Principle of Calibration Based on Process Calibration

Please read the information relating to the terms: nominal value, measured value and process value (see the Terms Relating to Dot Gain ).

•When you have a curve with reference values or a process curve: Input values = nominal values

Output values = process values

This curve portrays the desired, i.e. ideal printing process.

•When you have a curve with actual values or a data curve:

Input values = nominal values

Output values = measured values.

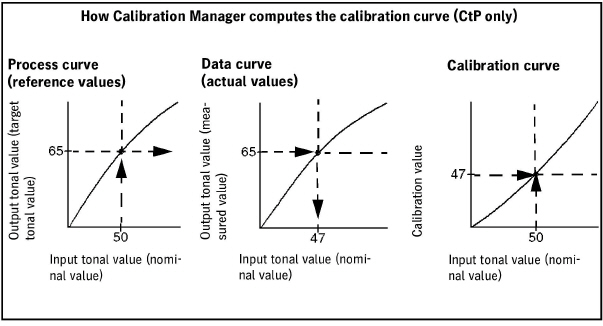

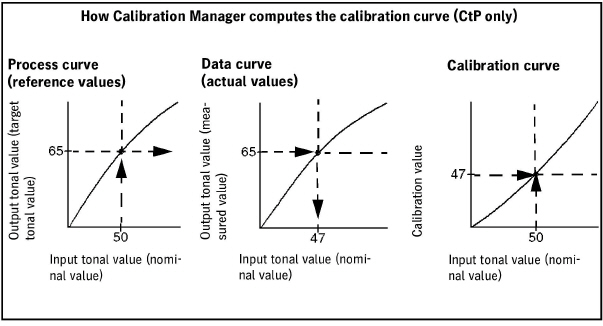

•Calibration curve: this is determined from the process curve and the data curve as follows (see also diagram below):

The actual dot percentage for a nominal value of 50% is to be 65%, for example, according to the process curve. However, this tonal value is not achieved at the nominal value of 50% but at 47% as shown in the data curve. For that reason, the calibration curve assigns the tonal value of 47% to the input tonal value of 50%.

This means that in the input data the input tonal value of 50% is replaced by the tonal value of 47% before screening.

Creation of a calibration curve (process calibration)