For an explanation of terms relating to process value and process curves, see page 31.

What benefits do multi process curve sets have?

The following requirements are met through the use of multi process curve sets:

•Reduction of the number of ImpositionOutput sequences. The process curve set used for a job can be selected automatically based on the type of printing material (coated, uncoated). Under certain conditions, it is not necessary for you to define an ImpositionOutput sequence specifically for each type of printing material.

•A mix of AM and FM screen systems in one job as part of object-specific screening is easier. Usually, different process curves are required for AM and FM screens (see visual dot loss). The use of multi process curve sets makes it possible for a process curve set to be selected automatically on the basis of the object-specific screen that is presently in use.

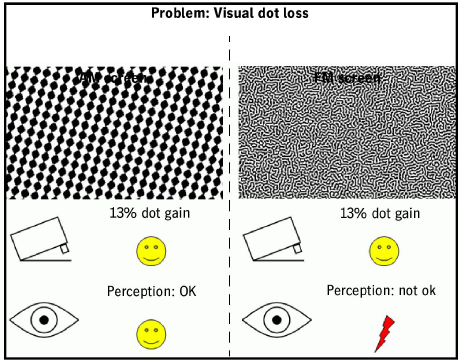

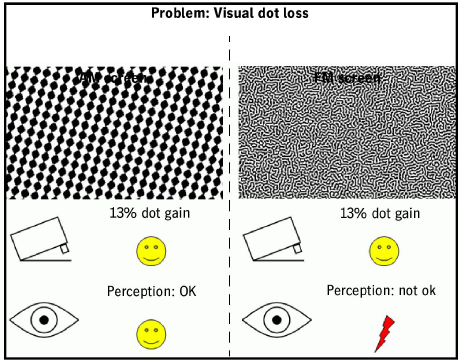

Problem of visual dot loss: In practice, you often cannot use the same process curves for (coarse) AM and (fine) FM screens. Even if the dot gains in an AM and FM screen are the same, the visual impression in the screens is still different due to the different frequency.

Taking the same dot gains in both an AM and FM screen, the visual impression that the objects in the FM screen make is unsatisfactory and poor in contrast. For that reason, higher target curves are often used in the field for FM screens. In other words, dot gain is increased in the midtone.

What Is a multi process curve set?

Process curve set

Properties like type of printing material or screen system are not explicitly assigned to a process curve set. Nevertheless, process curves are created taking into account certain properties of a printing process and in this respect can be grouped based on these properties. In a normal process curve set, these properties are usually seen in its name, for example, the name of the process curve set contains a type of printing material.

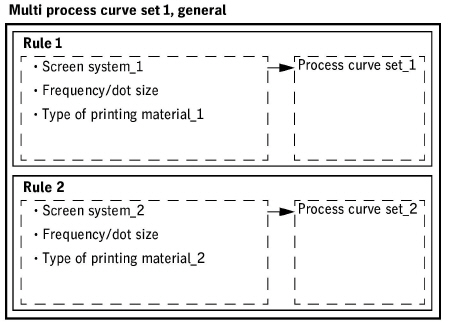

Multi process curve set

A multi process curve set encompasses one or more rules. Each rule assigns a process curve set to certain parameters (screen type, screen frequency, type of printing material). A process curve set is selected in the multi process curve set based on the rule. In other words, a multi process curve set is a number of process curve sets to which properties are assigned explicitly (and not just through their names).

These properties , that is, parameters, in a rule are:

•The type of screen system: You can select whether the process curve set will be used for all AM screen systems or for all FM screen systems or for each screen system.

•The frequency or dot size: You can specify an exact frequency if you select "AM screen systems". You can specify an exact dot size if you select "FM screen systems".

•The type of printing material: You can select whether the process curve set will be used for a specific printing material or every printing material.

A multi process curve set is first of all created like a container. Afterwards, you add rules that assign available process curve sets to the parameters named above. Each rule creates an entry in the multi process curve set.

The name of a multi process curve set is freely selectable, except for the fact that it is automatically prefixed with "MP:". All the process curves sets in a multi process curve set are referenced by this one name!

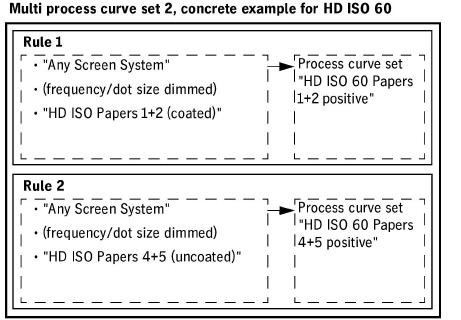

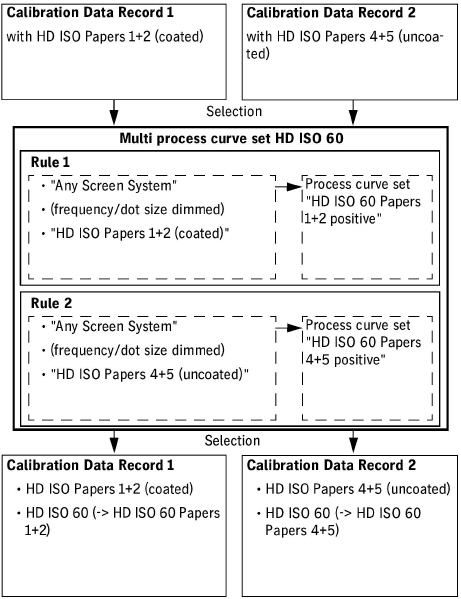

Below you will find diagrams with examples of two multi process curve sets. The concrete example for multi process curve set 2 shows a rule each for the different material types "HD ISO Papers 1+2 (coated)" and "HD ISO Papers 4+5 (uncoated)". By applying the rule, the matching process curve sets for coated and uncoated printing materials will be assigned to the different types of printing material.

Both process curve sets can be referenced through the name of multi process curve set 2.

Multi process curve sets in calibration data records

When you create a new calibration data record, the list box for process curve sets also displays any available multi process curve sets. See also the Create a New Calibration Data Record (Process Calibration). If you require a multi process curve set for a calibration data record, select it from this list box.

You can select the same multi process curve set for different calibration data records. All the process curve sets in it can be referenced through its name when you are editing the job (provided that the same multi process curve set is selected in the ImpositionOutput sequence; see also the Multi process curve set in the ImpositionOutput sequence ).

Example: In one calibration data record, you set "HD ISO Papers 1+2 (coated)" as your printing material and in another "HD ISO Papers 4+5 (uncoated)". You can select the same predefined multi process curve set "HD ISO 60" for both calibration data records.

In the first calibration data record, process curve set "HD ISO 60 Papers 1+2" is used for calibration. Accordingly, in the second calibration data record, process curve set "HD ISO 60 Papers 4+5" is used.

The diagram below illustrates this example:

Multi process curve set in the ImpositionOutput sequence

How do you select multi process curve sets for calibration in the Prinect Cockpit?

1.Open the ImpositionOutput sequence.

2.Select the calibration rule "Match, Else Error".

After that, any existing multi process curve sets are also available for selection of a process curve set.

By using multi process curve sets, you can see to it when editing a job that the proper process curve set is used automatically based on the screen, frequency/dot size and type of printing material.