The G7 standard is an offset standard; for this reason, there are similarities to classical offset printing (ISO 12647-2), similar to the check of primary and secondary colors.

But there are still some differences:

•The gray balance is predominant for the G7 check, and more emphasis is placed on it than for current ISO checks. In other words, the gray balance replaces the dot gain check in the G7 check.

•In contrast to the ISO check, the G7 check also evaluates the luminance values of the CMY and K patches with regard to color purity.

•The ISO standard determines the gray balance by comparing printed CMY gray patches with printed reference K-patches. In the G7 standard, the K-patches are not printed but the reference K-patches are calculated internally.

•The G7 applies the dynamic printing material adaption: primary and secondary colors are adapted to the current paper white.

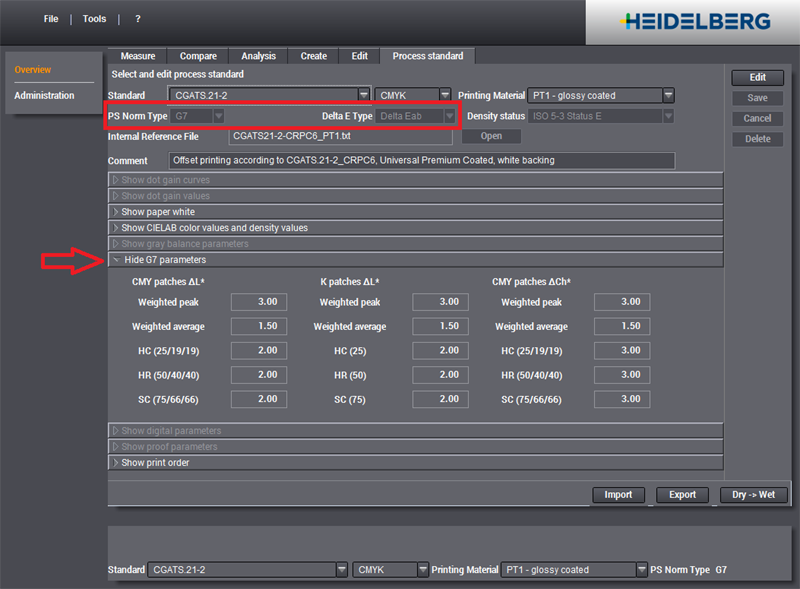

G7 process standards use a comparison with an internal reference file.

The following check dialogs are feasible for G7 process standards:

•Process standard

•Color values

•extended gray balance and

•Printing Materials

As the G7 standard supports the dynamic paper white adaption, the printing material check is redundant and part of the advanced evaluation just like the CMYK contone check (to determine the suppressed dot gain effect) and the density check.

Supported mini spots and test charts

The following mini spot test strips are normally used for a standard G7 check:

•P2P25/P2P51 — Target control strip

The target control strip is also suitable for setup and profiling.

•FMS — G7 control strip (Heidelberg)

•the IDE Alliance test strip 2009 or

•the IDE Alliance test strip 2013

These US mini spot control strips contain additional gray patches not present in classical control strips, in particular 25%, 50% and 75% patches.

•TC1617 test chart (combination of IT8.7/4 with the P2P51, see 'TC1617' (X-Rite G7) Test Charts)

Note: A warning is issued if you use another mini spot test strip or a test chart type that is not ideal for a proof check.

Select process standard for checking

The "G7 Process Standard" is selected as the reference for the G7 check because all the checks are pooled in "Measure". Prinect Color Toolbox supports several types of process standards. For this reason, you must select a G7 process standard when checking G7.

The "PS Norm Type" must display "G7" for a G7 check.