Set up a Digital Press in Central Device Manager

Like an offset sheetfed press, the digital press is also created using the Central Device Manager (CDM). In this way, you can plan digital printing operations at the Scheduler and are given feedback in Analyze Point.

The General Settings are identical when setting up a digital press.

1.To do this, go to "Administration > Settings > System" and select the computer name of the Prinect server.

2.Select "Add device" in the context-sensitive menu of the CDM.

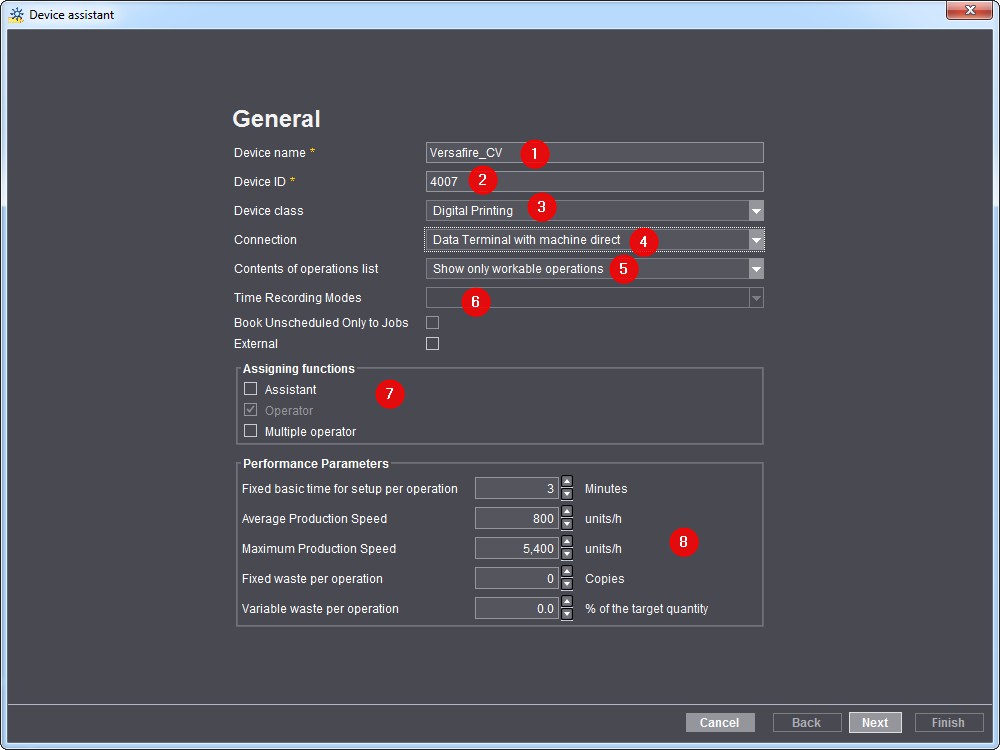

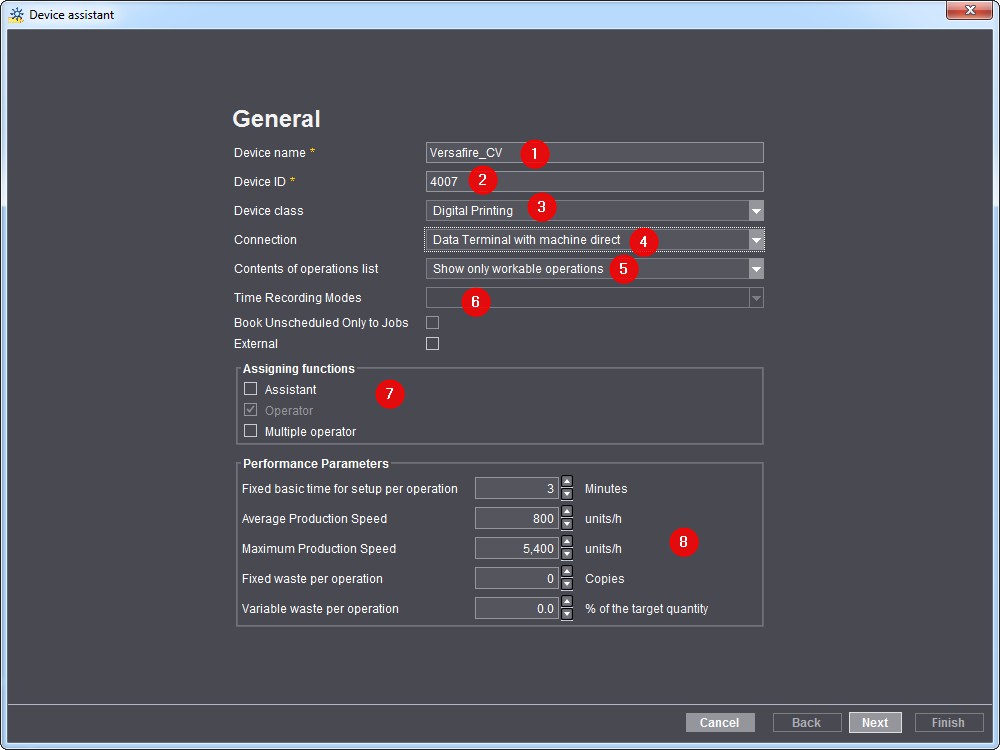

The "Device assistant" opens.

Device name

Under "Device name" (1), enter the designation for the digital press you wish to connect. The designation of the workplace/machine in the Prinect workflow must be unique. You may use no more than 30 characters. This designation serves as the press identification for the users in the entire Prinect workflow (in the scheduler and in Analyze Point, for example).

Device ID

Enter a device ID (2).

•The "DeviceID" must contain only the characters [a-z], [A-Z], [0-9].

•The device ID serves for unique assignment of the machine in your Prinect workflow. The device ID must be matched with the Management Information System (such as Prinect Business Manager).

•In the Digital Printing Terminal, the device is given the name entered as the device ID in this box.

Device class

Select the "Digital Printing" entry (3).

Select the connection type (4).

"Direct connection of the machine"

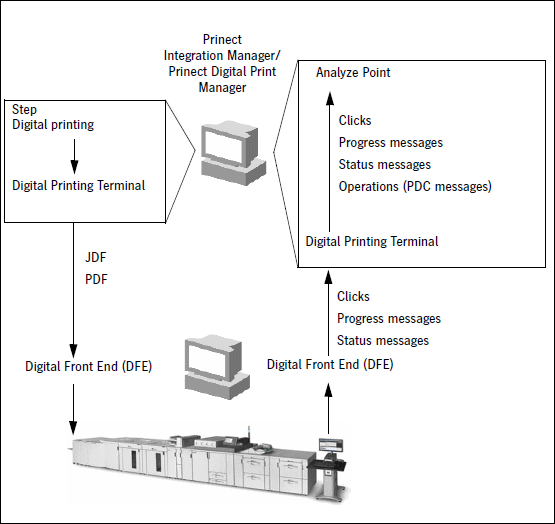

This connection type offers optimum integration into the workflow. In this context, the "Digital Printing" step first submits the jobs to the "Digital Printing Terminal" (see Digital Printing Terminal ).

The Digital Printing Terminal submits the jobs to the digital front end (DFE) where they are rendered and finally submitted to the digital press.

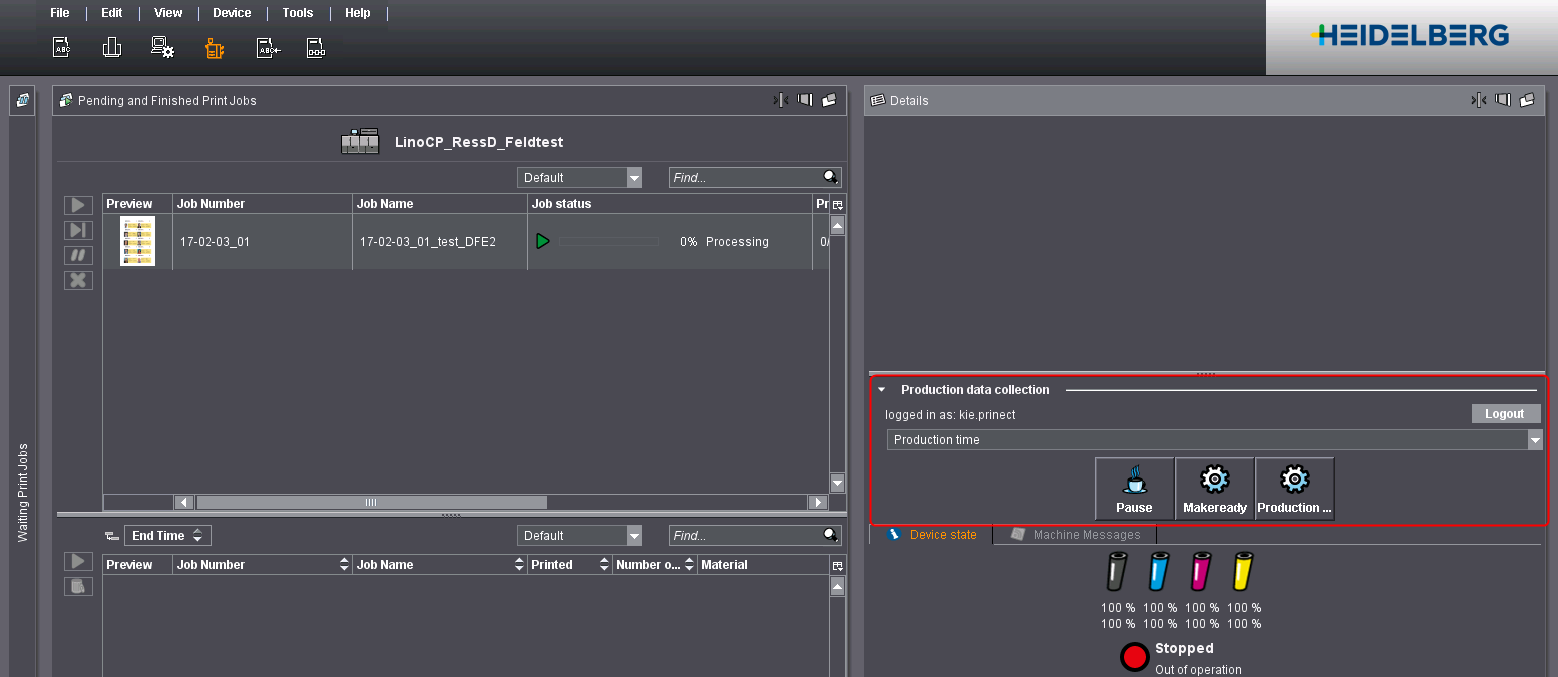

The press reports back various messages like impressions and progress messages to Analyze Point. PDC messages can also be recorded using the Digital Printing Terminal (see screenshot).

Press feedback is displayed in Analyze Point.

In this workflow, a pure production data collection runs using a Data Terminal. The Data Terminal is located on a separate PC and must not be mixed up with the production data collection via the Digital Printing Terminal. No job data are sent to the digital press and the machine does not report any messages to the Prinect Integration Manager/Prinect Digital Front End. This connection type is only relevant if you want to collect production data in your Management Information System and/or in Analyze Point.

Contents of operations list

Select the item you want in the list box (5). You can find a detailed description of the effects of the selection in Contents of operations list.

Time Recording Modes

Select the item you want in the list box (6). This function is available only for a Data Terminal connection.

You can find a detailed description in the Time Recording Modes.

Assigning functions

You define the roles for production data collection here (7). This means you define who can log in to the machine. You can select this option only with connection types "Data Terminal with machine direct" and "Data Terminal". You can find a detailed description of the roles in Assigning functions.

Performance Parameters

You do not need to change anything in the "Performance parameters" section (8). Defaults from the Master Data Store are entered in these boxes. The standard values entered here are only used as a template for calculating production times in a newly created operation. The calculated production times are then taken into account when scheduling the operation in the scheduler. In a Prinect workflow with a Management Information System (MIS), the production time are provided by MIS.

The "Performance parameters" are also important for the Planning Assistant. If no MIS data are available, these values are used to calculate how long an operation will take. For details about the Planning Assistant see Planning Assistant.

3.Click "Next".

4.Your next step is to select the machine type and connect to the press. Select one of the following links depending on your case:

·Set the machine type for Labelfire and Primefire

·Setting up a CTP device for PDF output for small-format platesetters

Set the machine type for Labelfire and Primefire

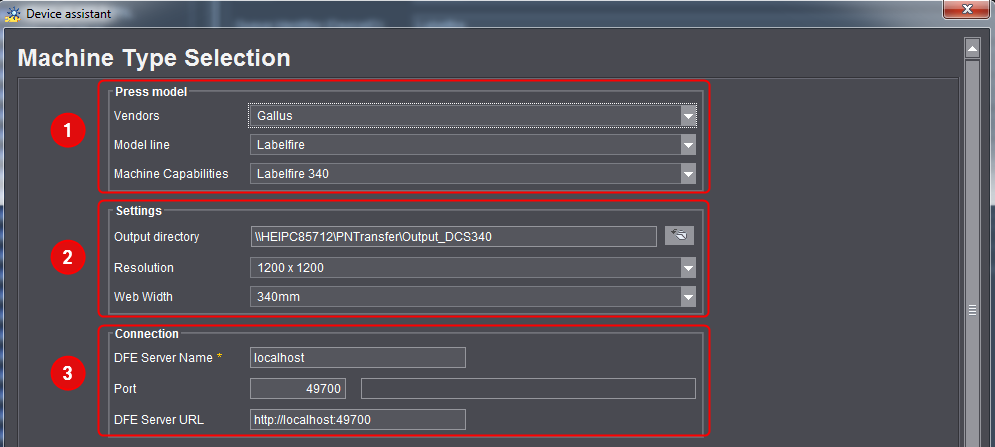

Press model (1)

Choose "Gallus" for Labelfire and the provider "Heidelberg" for Primefire. Model line and Machine Capabilities are set automatically.

Settings (2)

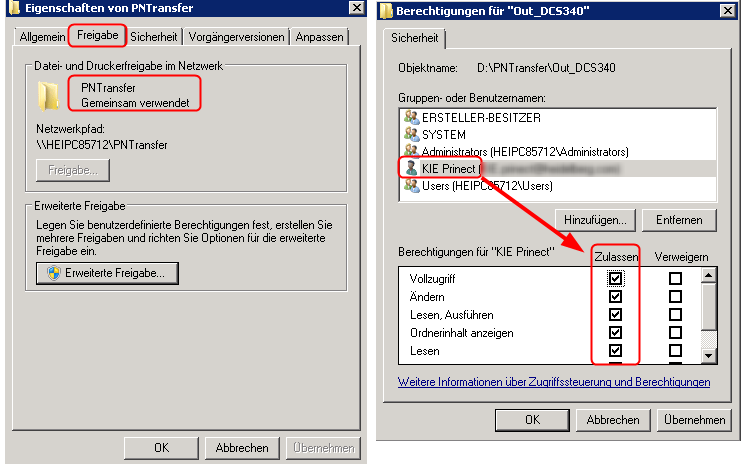

This is where you enter the folder to which the TIFF or BMP files will be written for the digital press. The press must be able to access this folder later. In other words, the folder has to be shared in the network, and there has to be a user having at least read and write permissions.

Connection (3)

Enter the server of the digital front end in "DFE Server Name" (Digital Front End). You can enter either the IP address or the name of the server.

The "Port" is entered automatically. You have to edit it only if you have changed it on the DFE server.

In "DFE Server URL", the URL is made up of the server name and the port. You do not need to make any changes in this box.

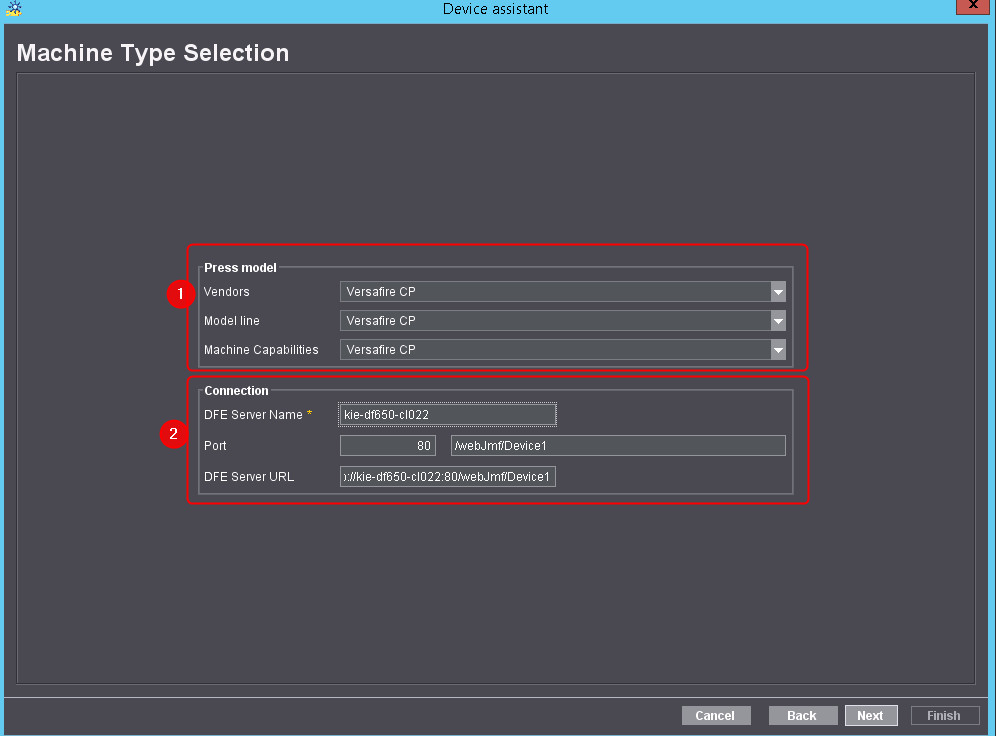

Setting up machine model parameters for Versafire CV/Linoprint CV, Versafire CP/Linoprint CP, Linoprint C and Ricoh Totalflow

Press model (1)

Select the vendor you want. Linoprint CV/CP was renamed to Versafire CV/CP; for this reason, the Linoprint CV/CP entries will remain for all presses set up until Prinect 2017. Choose Versafire CV/CP if you are setting up a new press. The functions of the machine models are identical.

Setting up machine capabilities for Linoprint C

•C751

You can choose from the following default finishing devices for Linoprint C751:

|

Machine Capability |

Explanation |

|---|---|

|

Fold_Staple_Interposer_SR5040_Trim_Punch4 |

Multi folder, high capacity stacker, booklet finisher SR5040 with Cover Interposer, front trimmer and 4 hole punching |

|

Fold_Staple_SR5030_Punch4 |

Multi folder FD5010, high capacity stacker SK5020, standard finisher SR5030 with 4 hole punching |

|

Interposer_SR5040_Trim_Punch4 |

Booklet finisher SR5040 with Cover Interposer, front trimmer and 4 hole punching |

|

SR5030_Punch4_Plockmatic |

Standard finisher SR5030 with 4 hole punching, Plockmatic |

|

Staple |

High capacity stacker SK5020 |

•C901

You can choose from the following default finishing devices for Linoprint C901:

|

Machine Capability |

Explanation |

|---|---|

|

SR5000_Punch4_Interposer_Plockmatic |

Standard finisher SR5000 with 4 hole punching and Cover Interposer, fully automatic Plockmatic (with page trimmer) |

|

SR5020_Punch4_Interposer_2Staple |

Booklet finisher SR5020 with 4 hole punching and Cover Interposer, two high capacity stackers |

Enter the server of the digital front end in "DFE Server Name" (Digital Front End). You can enter either the IP address or the name of the server.

The "Port" is entered automatically. You have to edit it only if you have changed it on the DFE server.

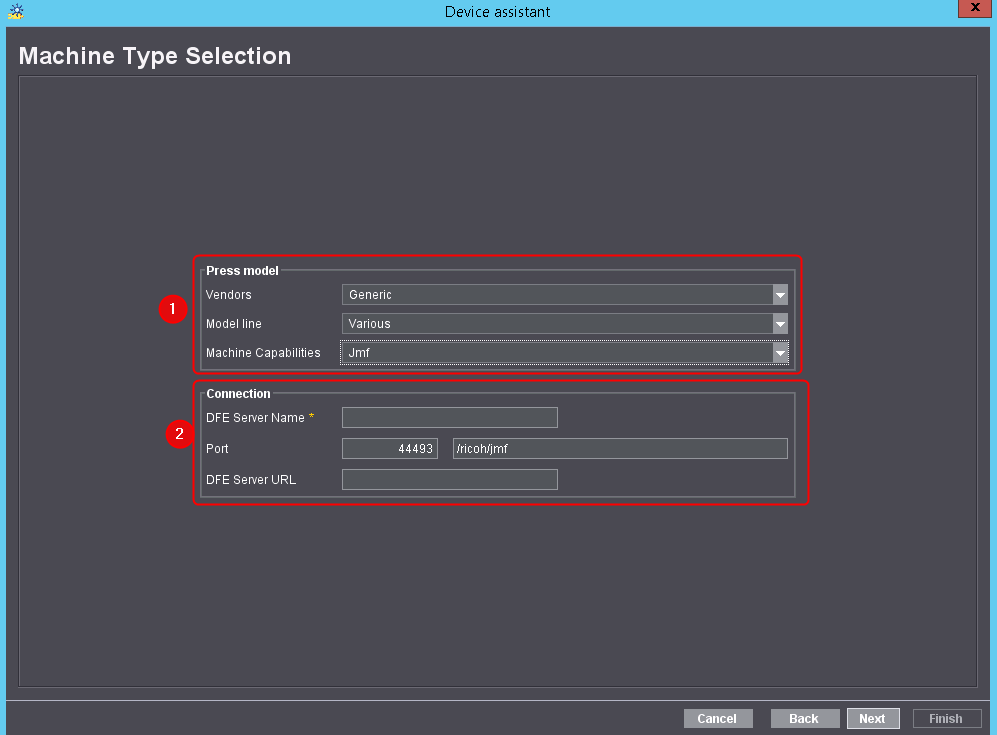

Setting up the machine model parameters for Canon, HP Indigo, Kodak NexPress, Konica Minolta, Ricoh, and Xerox

Machine model

Choose the respective manufacturer, the model line and the machine capabilities.

Connection

See Connection (2).

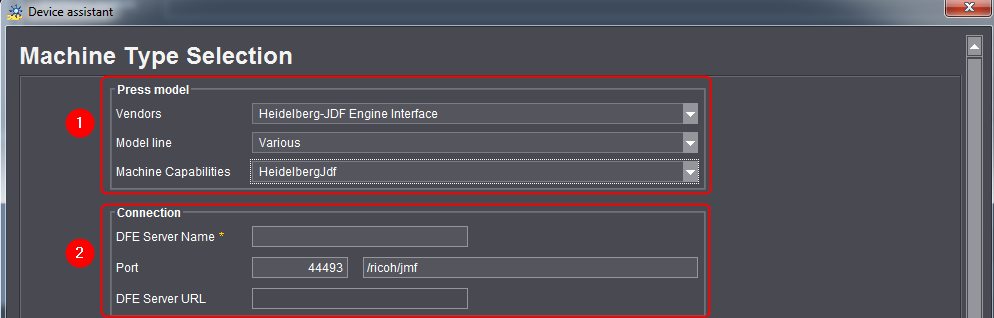

Setting up machine model parameters for third party presses with a Heidelberg interface

Compared to other third party presses, digital presses with Heidelberg interface can send feedback to the Prinect System, for example about the printing material. Please contact your vendor to find out if your machine has this interface.

To connect the press, select the following settings when setting up machine type parameters:

Press model (1)

Select "Heidelberg-JDF Engine Interface" as vendor. Model line and Machine Capabilities are set automatically.

Connection (2)

Enter the server of the digital front end in "DFE Server Name" (Digital Front End). You can enter either the IP address or the name of the server.

The "Port" is entered automatically. You have to edit it only if you have changed it on the DFE server.

Setting up machine model parameters for third party presses without a Heidelberg interface

All digital presses not yet supported by Heidelberg and have not implemented a Heidelberg interface (see Supported Digital Presses) can be connected via a generic interface. For such machines, the "Generic" item is available in the machine model list box. The Prinect System will write the PDF files into a specified folder later. This connection type does not allow any feedback from the digital press. This also means that the press cannot retrieve any printing material. Instead, a default group of printing materials is created automatically after you have set up the press. You can edit this group later. See Printing Materials and Substrates.

Press model (1)

Select "Generic" as the Vendor. The model line is set automatically.

Output directory (2)

Specify the folder (hotfolder) here to which Prinect Digital Front End is to write the PDF files for the digital press later. This folder must be shared.

The output directory is a root directory. In the Prinect workflow, all subdirectories of this directory are treated like "virtual printers" (see Printing Materials and Substrates). As a rule, the names of the subdirectories you set up there should match the names of the "virtual printers" you set up on the DFE.

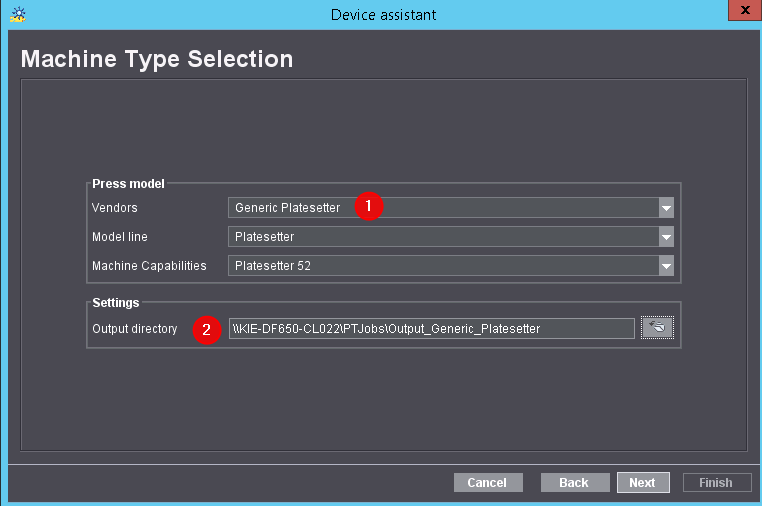

Setting up a CTP device for PDF output for small-format platesetters

Small print shops often have a simple small-format offset workflow in addition to their digital printing workflow. These print shops produce comparably simple products and use simple tools for press sheet generation. In this context, outputting a layout as PDF to the platesetter's RIP is often sufficient.

For this purpose, Heidelberg offers an option to create a layout in the Digital Front End and to output it as a PDF. The format is restricted to a maximum size of 656 mm (width) x 530 mm (height).

To output such a PDF, a digital press has to be set up at the CDM. After having made general settings (see General settings), make the following settings in the "Machine Type Selection" dialog:

Select "Generic Platesetter" (1) as the vendor. For Output directory (2), select a folder where the PDFs for the RIP are to be written later. The RIP has to have access to this folder as well.

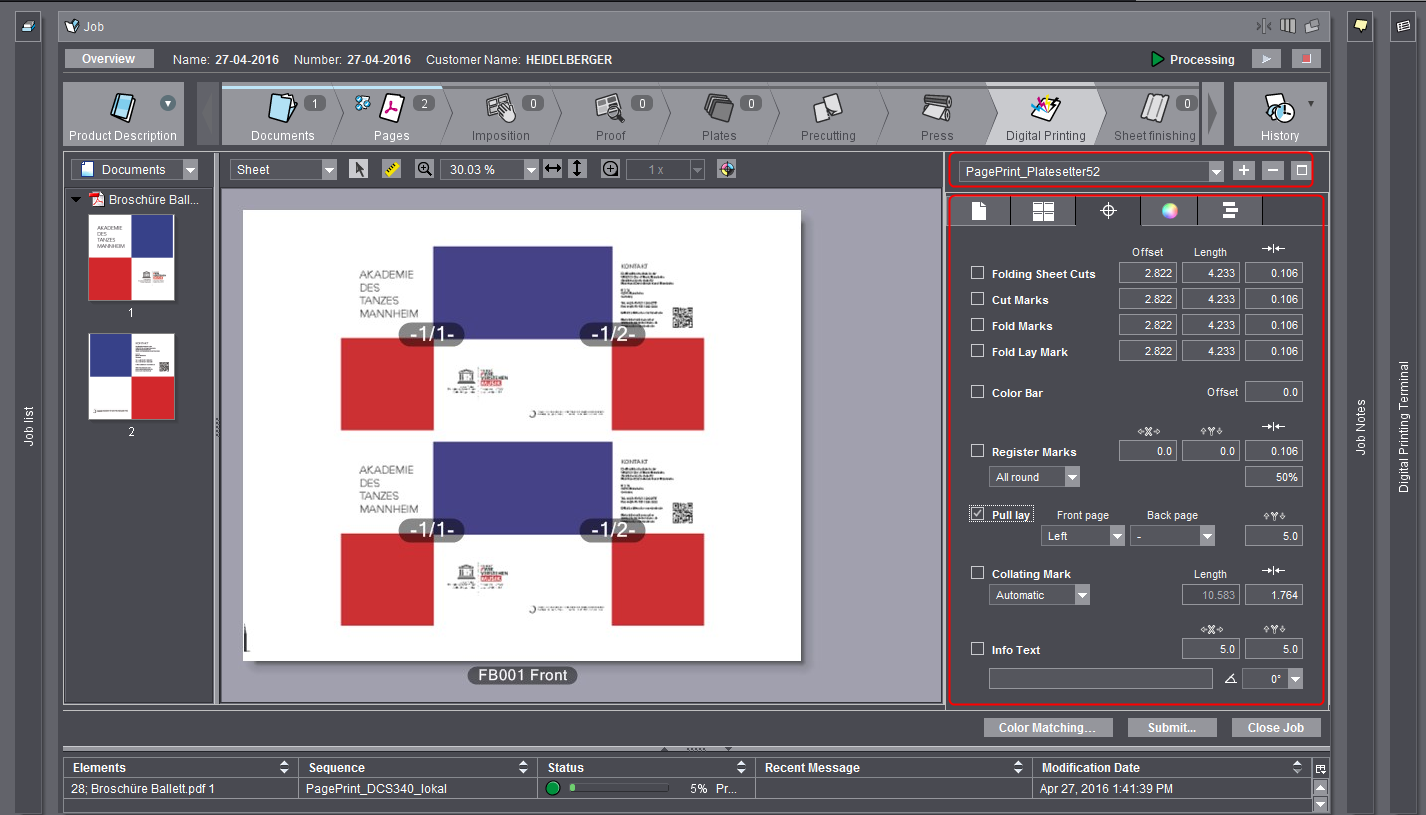

You can then set up a "PagePrint" sequence selectable in the "Digital Printing" step for the new device. Here you can edit the plate format, specify the position of the sheet and place pull lays.

Further Device assistant steps for Data Terminal devices

For digital presses of connection types "Data Terminal with machine direct" and "Data Terminal", the Device assistant offers steps for setting up production data collection parameters. These settings are identical to those of other Data Terminal devices. In a direct connection without Data Terminal you go directly to the Device Assistant - Summary window.

For Data Terminal steps, see:

•Device Assistant - "Assigning operation groups" and "Assigning operations"

•Device Assistant - Assigning User Groups