What needs to be taken into account in a workflow with an MIS?

If you use an MIS in your Prinect Workflow system, cost centers, user data and operations (SFDC messages) should be synchronized between the MIS and the Master Data Store (MDS). You can then synchronize the MDS and the Prinect Press Center / Prinect CP2000 Center.

Please contact your Prinect Service if you want to run synchronization between the MIS and the Prinect Manager.

Synchronization is carried out in two steps:

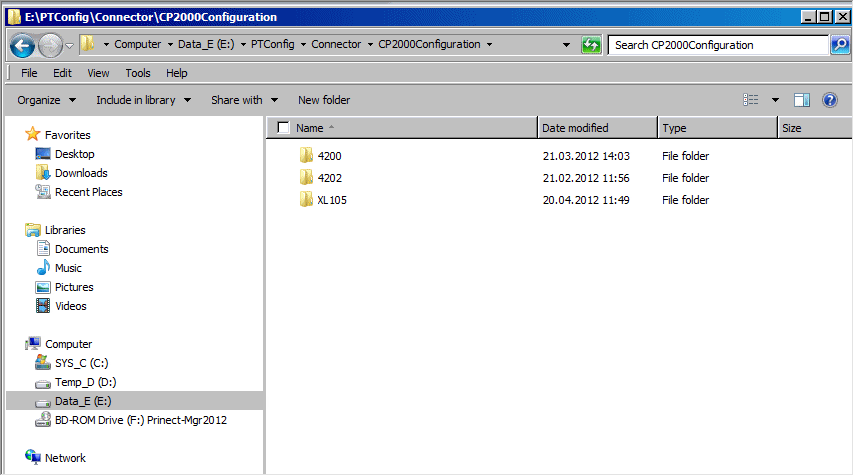

1.Three XML files are automatically generated via the interface "Export of the CP2000 configuration". This always takes place when defining a new CDM device. When the device features are altered, the XML files are overwritten. The files are saved in a subfolder for each device. The folder is named like the device (DeviceID). The XML files contain the cost centers, the operation groups (cost type groups), the operations (SFDC messages), and the staff.

The XML files are saved in a user-definable directory:

\\Prinect Server\PTConfig\Connector\CP2000Configuration\

2.Import the previously generated XML file on the press:

·In Prinect Press Center, use the menu

"Service >Integration/System > PDC configuration > <import icon>".

·In Prinect CP2000 Center, use the menu

"Service > Prinect configuration > PDC configuration > Transfer".

Note: You must run the import for each of the presses set up in CDM.

If you now wish to set up a new CDM device, the XML files are automatically generated and saved in the source directory defined above. A subfolder named according to the DeviceID is created for each device.

Importing the XML file in Prinect Press Center

Automatic import of the SFDC (PDC) configuration

Automated import is possible as of Prinect Integration Manager/Prinect Pressroom Manager version 2011 and Prinect Press Center version V11B and later.

In this case, the SFDC configuration is imported automatically after the "Workplace Interface" data storage has been configured and activated.

Heed the following:

•The "Workplace Interface" data storage must have been configured successfully for the connected press and set to active (in the "Active data storage devices" column).

•Import can take a few seconds.

•Check whether or not import was successful after data storage device configuration with "System > Service > Integration / System > Prinect Configuration > PDC configuration".

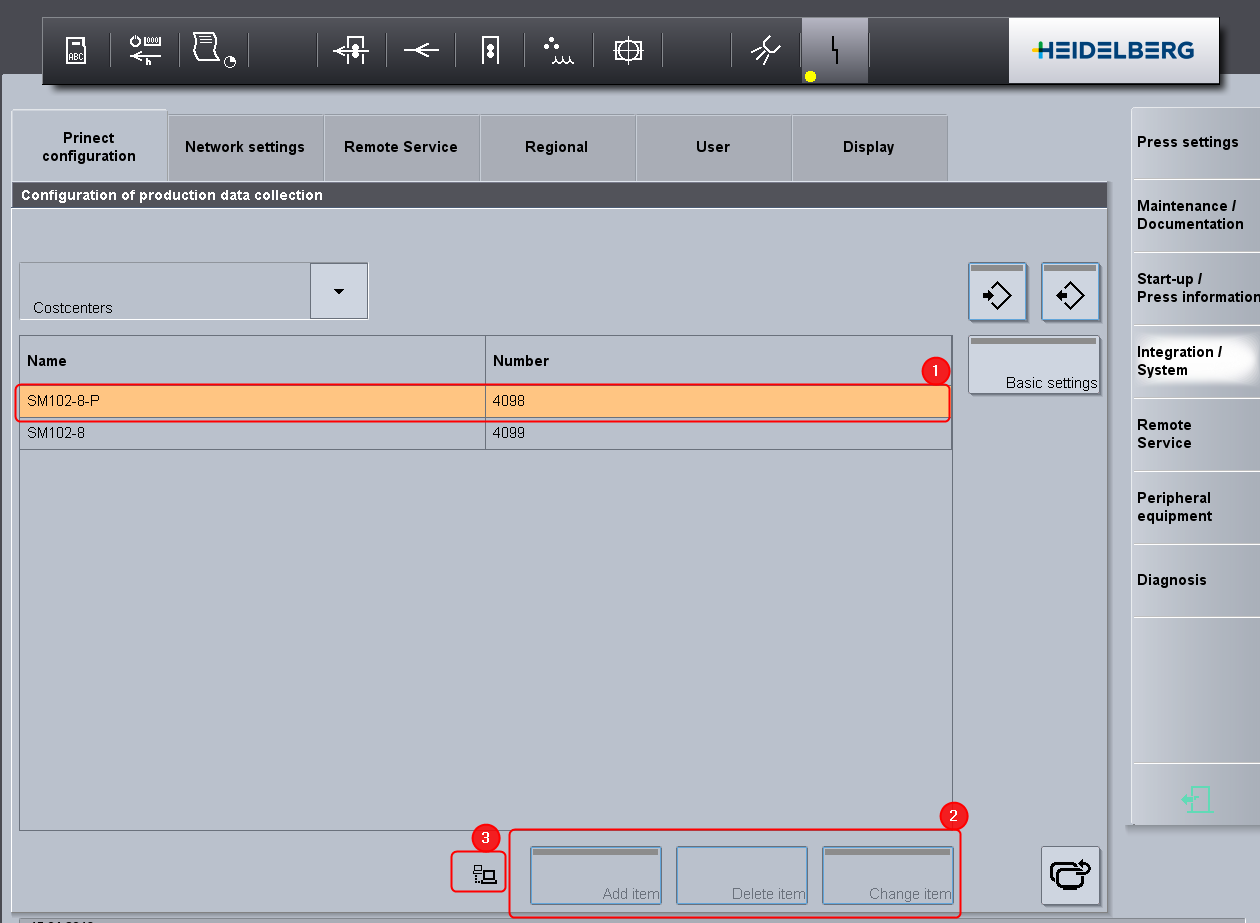

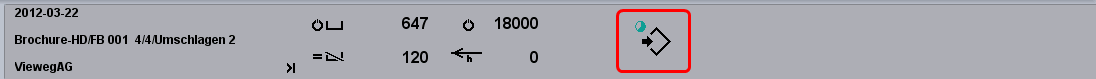

·The name and the number of the cost center(s) must match the configuration in Prinect Integration Manager/Prinect Pressroom Manager (1).

·The buttons for manual input are not active during automatic import (2).

·The network icon indicates that the automatic import was successful (3).

Run a manual import if you are in doubt. See Manual import of the SFDC (PDC) configuration.

•In case of an automated import, all locally defined cost centers and operations (SFDC messages) are deleted and overwritten by those of Prinect Integration Manager/Prinect Pressroom Manager.

Please contact our Prinect Service (support.prinectpress@heidelberg.com) if you want automated import to be disabled.

Manual import of the SFDC (PDC) configuration

The generated XML file is imported using the import function.

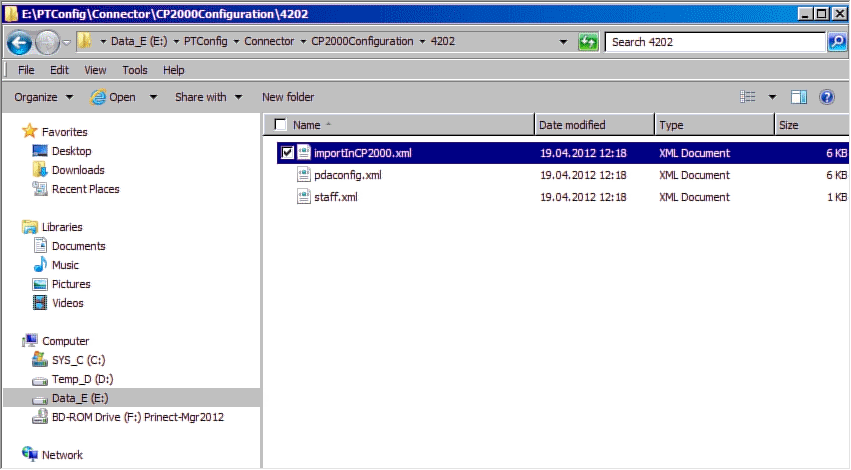

The generated XML file "importInCP2000.xml" must be imported.

1.Go to the corresponding Prinect Press Center press for which you have generated the XML file.

2.Go to the menu "Service > Integration System > PDC configuration" and press the button shown below.

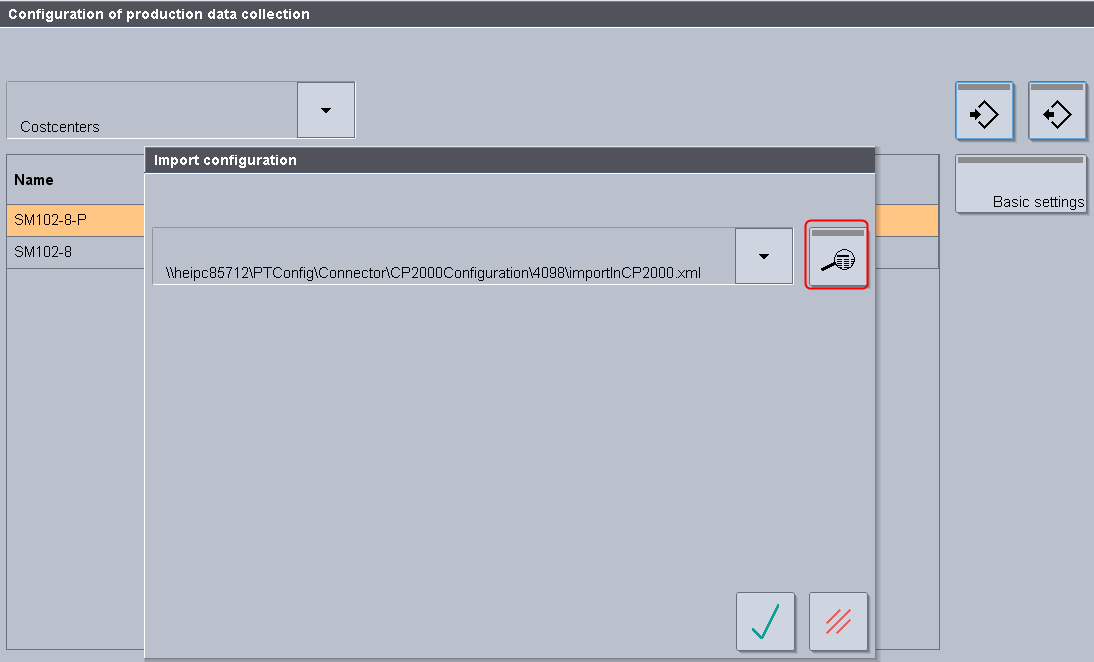

The window "Import configuration" appears.

3.Click the magnifier icon to specify a path for the XML file.

The name of the XML file to be imported is always "importInCP2000.xml".

In our example this is: \\KIE-ESXPN1005\PTConfig\Connector\4202\importInCP2000.xml.

4.Confirm your input with the "green check mark" button.

5.Confirm the path once again with the "green check mark" button.

The import icon appears briefly while the network connection is being set up.

The configuration window closes and the file is read.

Importing the XML file in Prinect CP2000 Center

The import of the generated XML file depends on the Prinect CP2000 Center software version. As such, we describe the following two cases here:

•Case A: Prinect CP2000 Center with import function, version v41 and later.

The generated XML file "importInCP2000.xml" must be imported.

•Case B: Prinect CP2000 Center without import function, version v41 and earlier.

The generated XML files "pdaconfig.xml" and "staff.xml" have to be copied into a directory manually.

Case A:

1.Go to the corresponding Prinect CP2000 Center for which you have generated the XML file.

2.Go to the menu "Service > Prinect configuration > PDC configuration > Transfer".

You can find a detailed description in the Prinect CP2000 Center operating manual.

3.Click the "Data storage configuration" button.

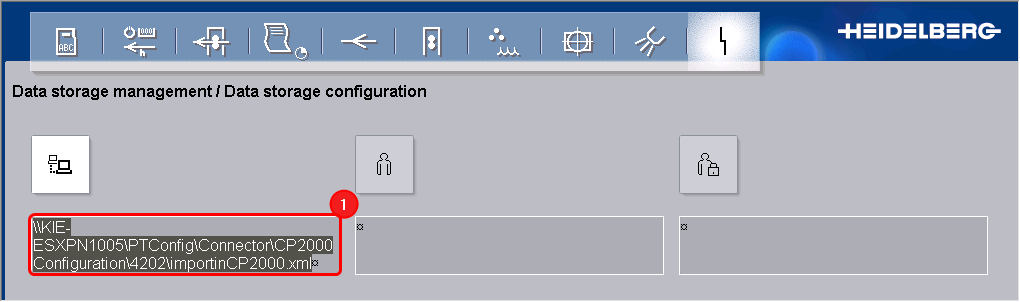

4.Enter the transfer directory and the name of the XML file in the "URL" input field (1).

The name of the XML file to be imported is always "importInCP2000.xml".

5.If necessary, enter the user name and password for access to the data storage unit.

You can find a detailed description in the Prinect CP2000 Center operating manual.

6.Confirm the entry.

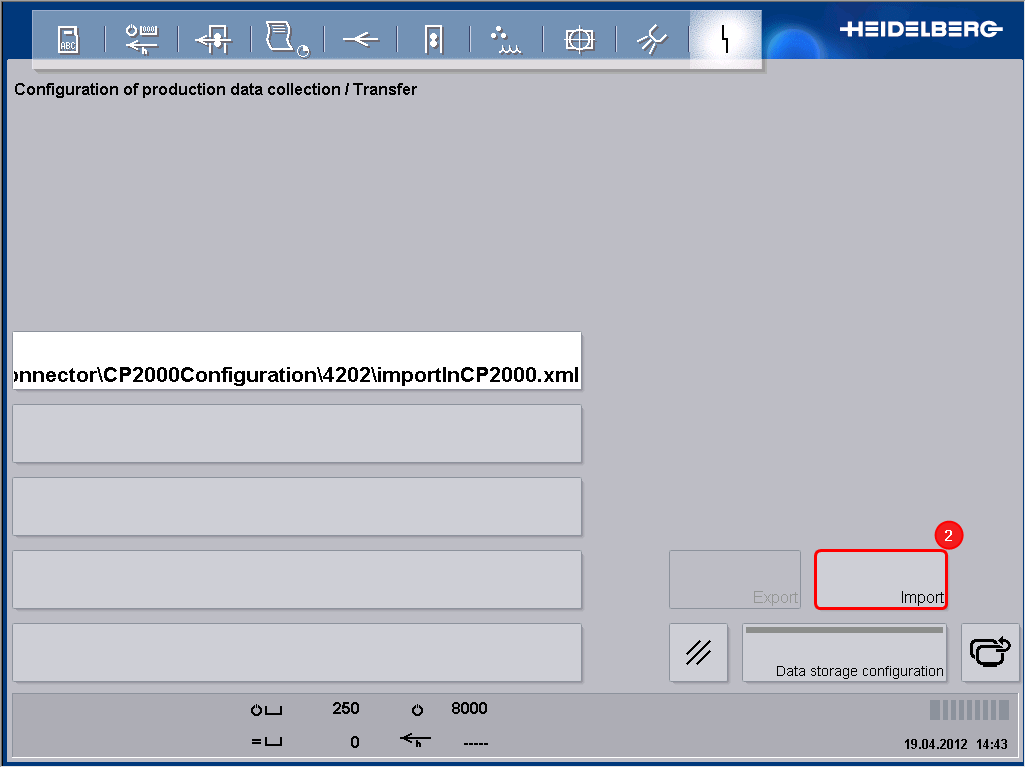

The window closes, and the menu "Configuration of production data collection/Transfer" appears.

•The transfer directory is accepted, and the button "Import" turns active (2).

7.Click the "Import" button (2).

The import is started and takes a few seconds. No message is issued stating that the import was successful. However, if the import is unsuccessful, this is displayed by a yellow service symbol.

Case B:

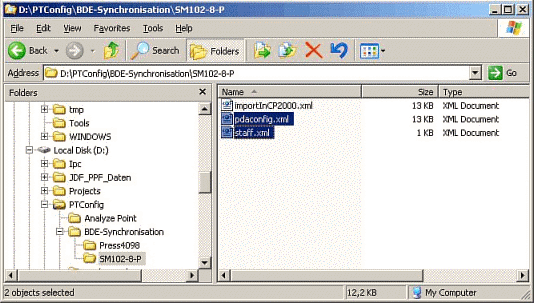

As no import function is available in this case, the generated XML file "importInCP2000.xml" cannot be used. The automatic export of the CP2000 configuration generates two more files which are also available in the IPC (Prinect CP2000 computer). These are the files:

•pdaconfig.xml

•staff.xml

These are also located in the generated device directory. For example "\\KIE-ESXPN1055\PTConfig\Connector\4202".

These two files have to be copied manually into the directory "C:\CP2000Ap\bin" on the IPC (Prinect CP2000 computer). The old files are simply overwritten here.

Finally, restart the Prinect CP2000 Center.

Heidelberg supports a number of digital presses that can be connected online to the Prinect system. In addition, Heidelberg provides all machine manufacturers with a JDF/JMF interface for online connection. Machines that cannot be connected online can be connected via a PDF connection or a Data Terminal.

You can find a list of the supported machines that can be connected online in: Supported Digital Presses.

In principle, there are the following different connection types:

•Online Connection of Other Manufacturers

•Data Terminal Connection (Offline Connection)

Connection Types for Digital Presses

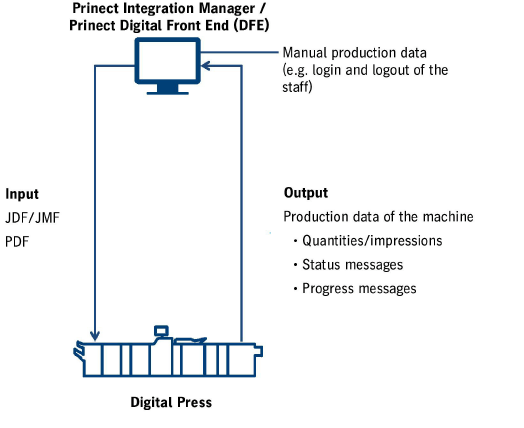

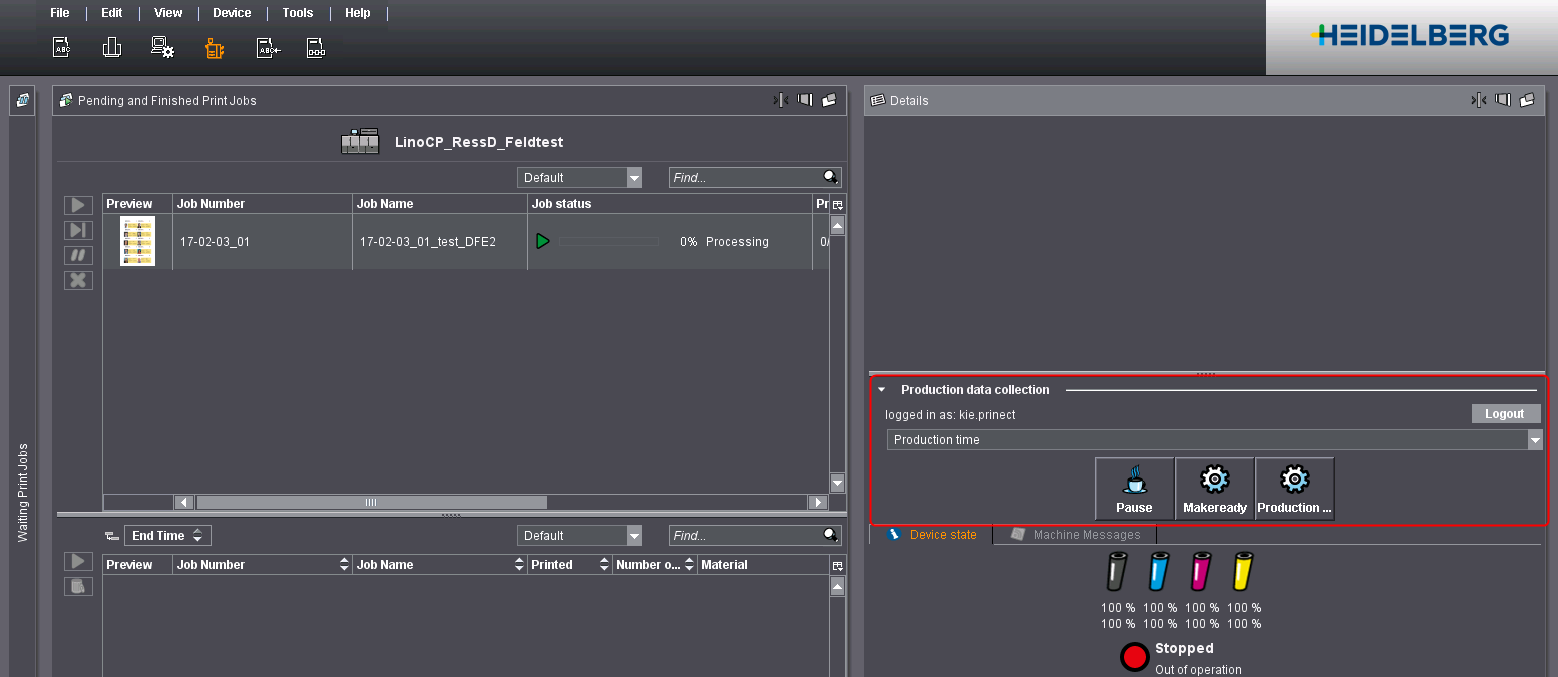

With this connection type, the machine communicates directly with the Prinect Digital Front End (DFE). On the Prinect DFE, the jobs are prepared (imposition, color management, etc.) and then sent to the press to be printed. The machine automatically reports back production data like quantities and status messages. Other production data like login and logout of the staff can be recorded manually on the Prinect DFE (within the Digital Printing Terminal) (see screenshot below). Finally, all production data display in Analyze Point.

Online Connection of Other Manufacturers

Heidelberg provides all machine manufacturers with a JDF/JMF-based interface for the connection to Prinect. This makes online connection also possible for machines that are not found in the list of supported machines. Machines with this interface can receive and report back the same data. The only difference lies in the configuration of the connection. See Set up Connection for Third-party Machines with JDF/JMF Interface.

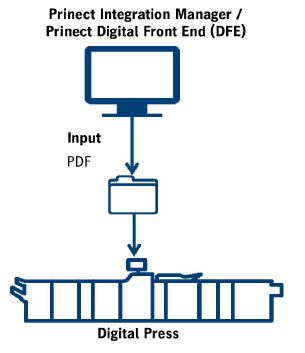

All digital presses that cannot be connected online can be connected through a generic interface. With this connection type, the Prinect DFE places the imposed PDF in a set folder that the press must access.

In contrast to the online connection, the press does not send any feedbacks to the Prinect DFE. This also means that the press cannot request any printing material. Instead, a default group of printing materials is created automatically after you have set up the press. You can edit this group manually (see Printing Materials and Substrates).

Data Terminal Connection (Offline Connection)

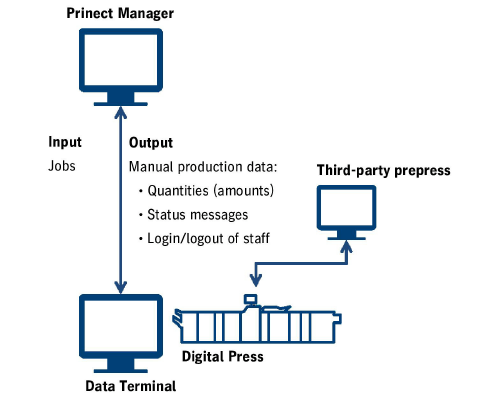

With this connection type, there is no direct communication between Prinect and the machine. It is solely for manual production data collection for a connected MIS and/or Analyze Point. The job data generally come to the machine from a third-party prepress system.

Heidelberg supports a number of digital presses that can be connected online. The table below lists supported presses. Digital presses that cannot be connected online can be connected through a generic interface ("Generic").

|

Vendor |

Model line |

Note |

|---|---|---|

|

Heidelberg |

Primefire |

With these machines, rendering can be done directly in the Prinect DFE. |

|

Gallus |

Labelfire |

|

|

Versafire CV/EV |

Versafire CV/EV |

|

|

Versafire CP/EP |

Versafire CP/EP |

|

|

Linoprint C |

Linoprint C751 |

|

|

Linoprint C901 |

||

|

Heidelberg JDF Engine Interface |

Various |

Third-party machines with a JDF/JMF interface are connected through this. |

|

Generic |

Various |

Third-party machines with no JDF/JMF interface are connected through this. |

|

Generic |

Platesetter |

PDFs are output to small-format platesetters through this (suited for simple offset workflow). |

|

Canon |

Canon |

To connect, you need the Fiery System 9 or 10 |

|

HP Indigo |

HP |

To connect, you need the HP SmartStream Production Pro Server or a machine with the HP Onboard Server. |

|

Konica Minolta |

Konica Minolta AccurioPRESS C2060 |

To connect, you need the Fiery System 9 or 10 or IC-603. |

|

Konica Minolta AccurioPRESS C2060 |

||

|

Konica Minolta AccurioPRESS C2060L |

||

|

Konica Minolta bizhub PRO C754 |

||

|

Konica Minolta bizhub PRO C70hc |

||

|

Konica Minolta bizhub PRESS C70hc |

||

|

Konica Minolta bizhub PRO C6000 |

||

|

Konica Minolta bizhub PRO C7000 |

||

|

Konica Minolta bizhub PRESS C6000 |

||

|

Konica Minolta bizhub PRESS C8000 |

||

|

Kodak Nexpress |

Nexpress |

Nexpress machines do not report back any data like machine status, quantities and progress messages. |

|

Ricoh Totalflow |

Ricoh Pro C7100 series |

Ricoh Totalflow uses a different DFE compared to the "Ricoh" connection. This means that the finishers are driven like in the case of Versafire machines. |

|

Ricoh Pro C9100 series |

||

|

Ricoh Pro VC60000 |

||

|

Ricoh |

Ricoh |

To connect, you need the Fiery System 9 or 10 |

|

Xerox |

Xerox |

To connect, you need either the Fiery System 9 or 10, or the Freeflow JMF Service |