Assign Plate Material ("Plates")

Plate materials are set up separately in the Prinect Business Manager and Prinect Integration Manager (import not possible). If plate materials are set up on both sides, usually feedback about the correct setup is sent to the Prinect Business Manager (no intervention needed).

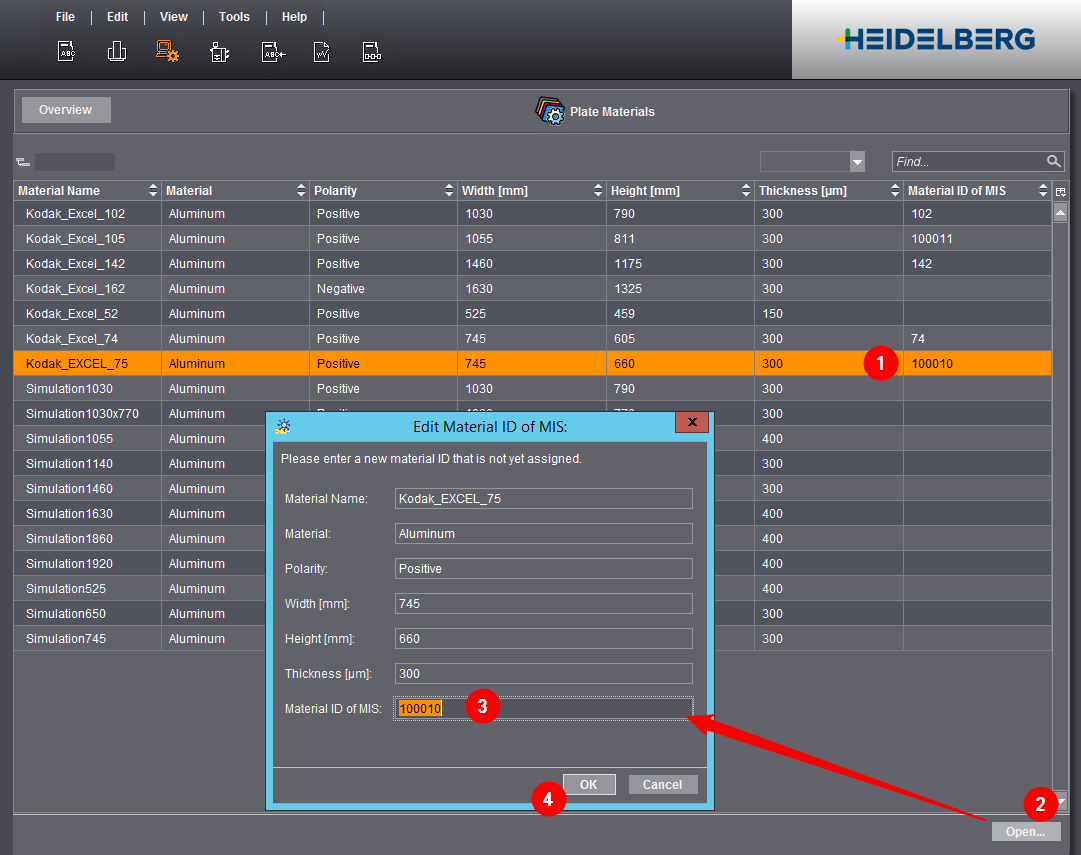

In the case of re-imaging and jobs that are not sent as JDFs by the Prinect Business Manager, a feedback is possible only if the IDs of the plate materials are the same ("MaterialID" in the Business Manager or "Material ID of MIS" in the Integration Manager). To make sure that the IDs match, the plate materials must be assigned to each other. This is done in the Web UI or in the administration of the Integration Manager. Below we will describe the process through the Web UI.

Procedure

Proceed as follows to assign the plate materials of the Business Manager and the Integration Manager to each other.

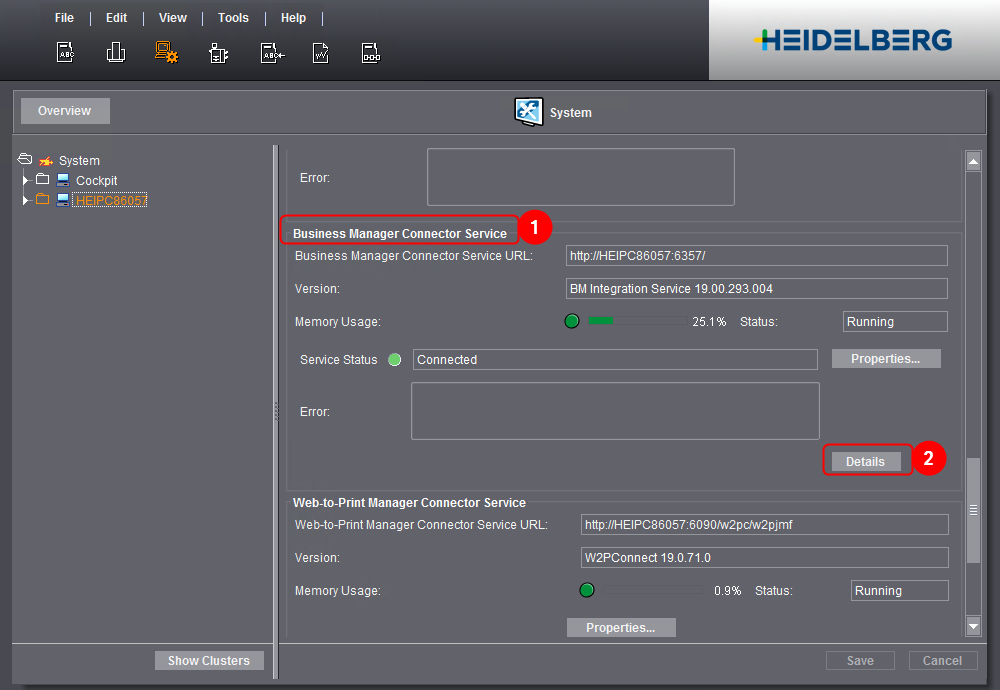

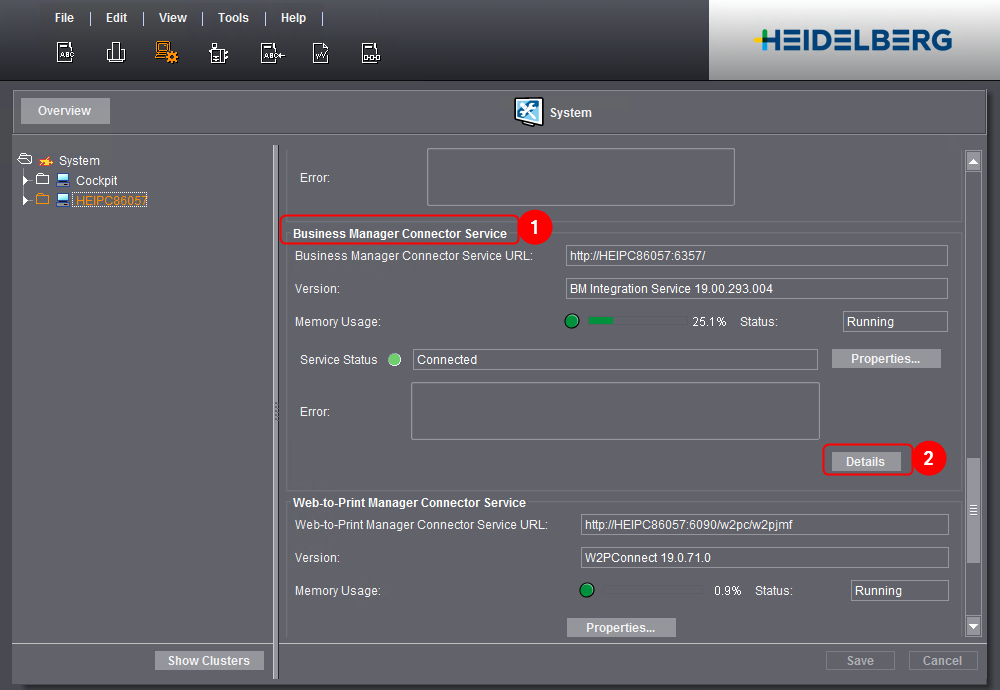

1.In the Prinect Cockpit, go to "Administration > System".

2.Click the Prinect server in the left column.

3.Scroll to "Business Manager Connector Service" (1) on the right side.

4.Click "Details" (2).

The "Configuration Status" window opens in the Internet browser.

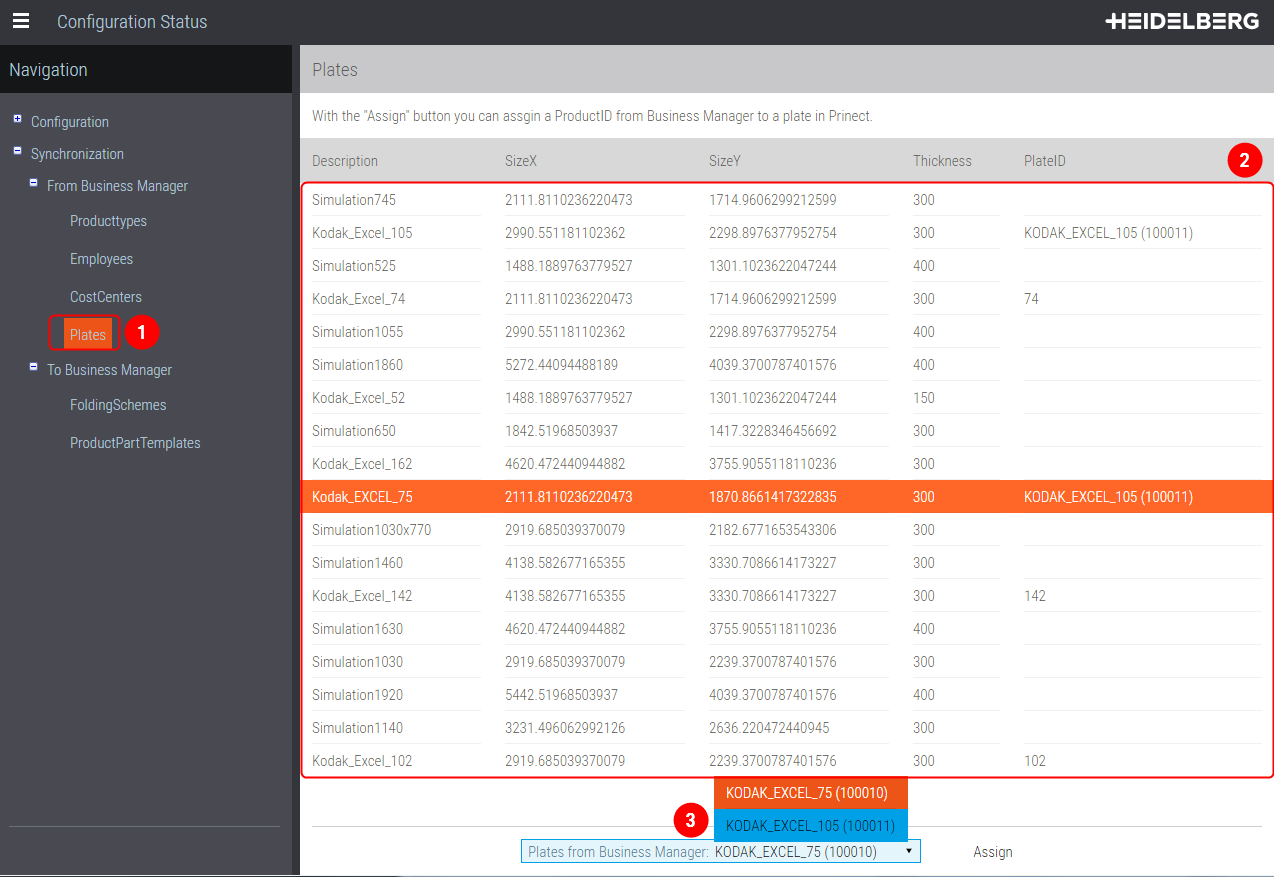

5.Go to "Synchronization > From Business Manager > Plates" (1).

The list displays all plate materials set up in the Prinect Integration Manager (2). The "PlateID" column shows the currently assigned "MaterialID" of the Business Manager.

The list box (3) displays all the plate materials set up in the Prinect Business Manager. The number in parentheses is the "MaterialID".

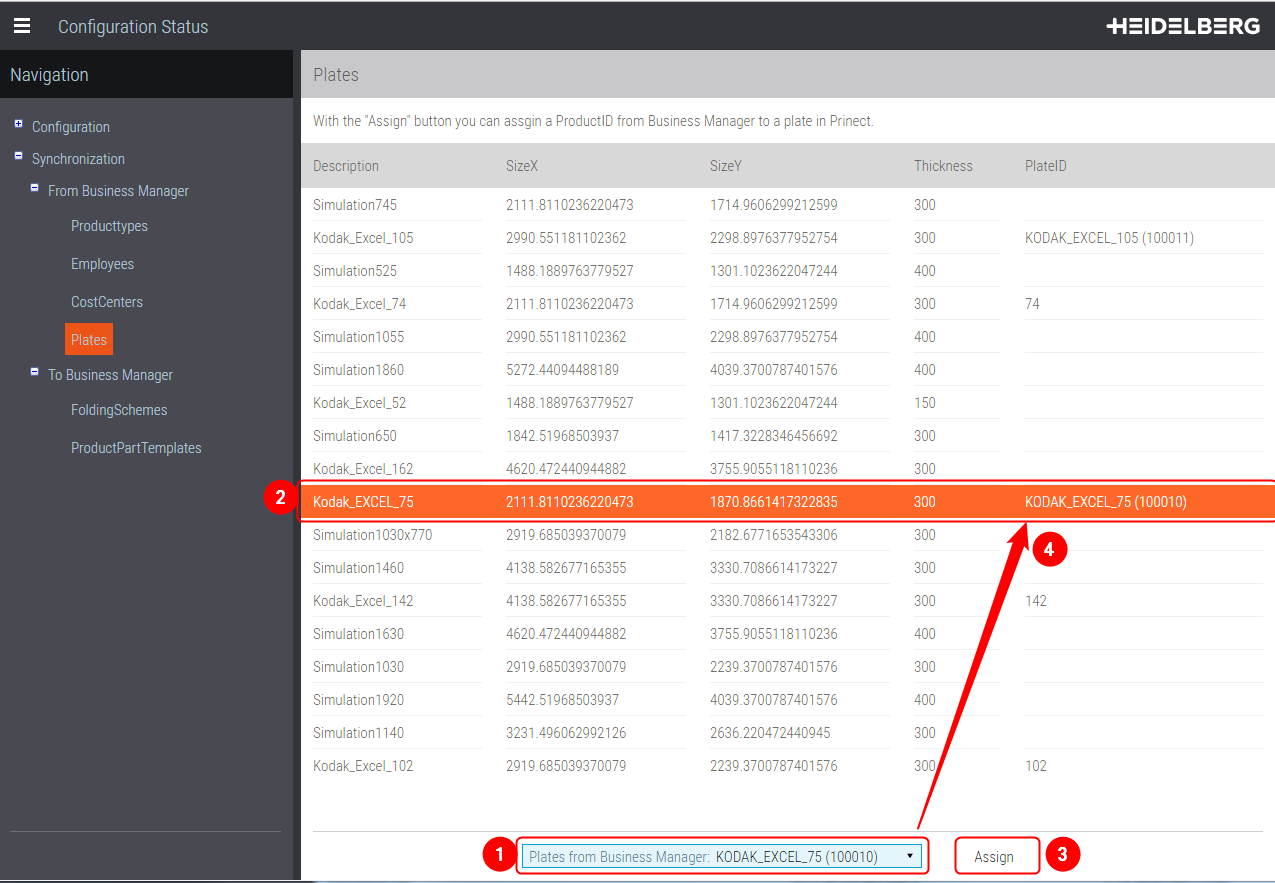

6.To assign the plate materials to each other, select them (1/2).

7.Click "Assign" (3).

Assignment is finished whenever the plate material displays in the "PlateID" column (4).

Note: If the MaterialID from the Business Manager is known, the plate materials can also be assigned in Administration in the Prinect Cockpit.

Master Data Import to the Prinect Business Manager

To avoid creating master data twice, you can import master data from Prinect Signa Station to the Prinect Business Manager.

Which master data can be imported?

You can import the following master data from Prinect Signa Station:

•Manual folding schemes

Only manual folding schemes are imported. All standard folding schemes are already created in the Prinect Business Manager.

•Product Part Templates

The import of product part templates is needed especially for gang jobs in the packaging workflow.

•No configuration is needed in the Prinect Business Manager.

•Data can be re-imported if they change. Old values are overwritten.

Import Folding Schemes and Product Part Templates to the Prinect Business Manager

You can import folding schemes and product part templates from Prinect Signa Station. Below we will describe an example of how to import manually created folding schemes. Product part templates are imported in the same way.

To import manual folding schemes from Signa Station to the Prinect Business Manager, proceed as follows:

1.In Prinect Cockpit, go to "Administration > System".

2.Click the Prinect server in the left column.

3.Scroll to "Business Manager Connector Service" (1) on the right side.

4.Click "Details" (2).

The "Configuration Status" window opens in the Internet browser.

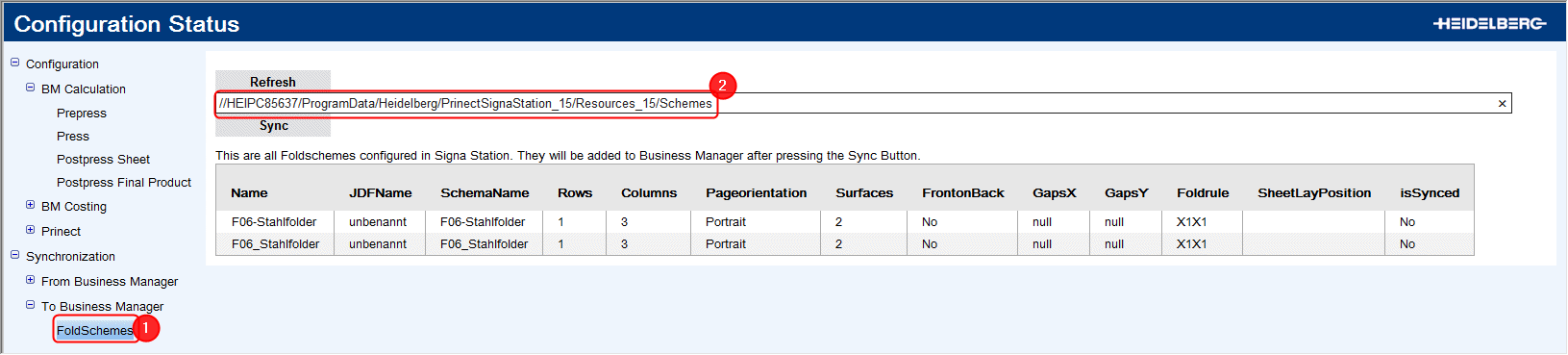

5.Go to "Synchronization > To Business Manager > FoldingSchemes" (1).

The list shows all manually created folding schemes of Prinect Signa Station. The "Ok/No" attribute in the "isSynced" column tags the folding schemes that are imported/not imported.

6.To synchronize the folding schemes, click "Sync" (2).

The folding schemes are imported automatically. Import is finished as soon as the "OK" attribute displays in the "isSynced" column.