Sequence Templates - Smart Templates

Smart templates are groups of sequence templates that group all the steps required for a workflow in automated processes as is found, for example, in a web-to-print environment. In contrast to group templates (see the Group Templates) that are made up of fully setup sequence templates, smart templates generally just contain placeholders for the different types of sequences that are linked together in the order they will be processed. These placeholders are characterized only by the sequence type and are not assigned any parameters when the smart templates are being defined. Only when the job is being processed are the required parameters sent to the template placeholders. The processing parameters result from the job properties as defined, for example, in the web-to-print application or in the MIS (Management Information System).

Note: In single cases, it may make sense to insert real sequences instead of placeholders for certain sequence types, e.g. AutoSheet or PageProof, because the flexibility found with dynamic sequence replacement is not needed in these cases. For that reason, real sequences are also available for smart templates.

In other words, the smart templates provide a "framework" for each of the steps in the Prinect workflow and for the links between these steps. This means that a suitable smart template can be created for each editing process possible in a web-to-print environment, for example, for booklets with saddlestitching, for postcards, calendars, etc. Customized smart templates can also be created for variants that are needed because of different sizes, different printing materials and output to different presses or finishing machines.

The basic data of the print job like the product type (brochure, etc.), the size, job volume, print run, colors, binding mode are defined by the web shop customers when they place an order. These parameters provide the basis for selecting a suitable smart template and also for the options that are used to set up each of the sequences. In addition, based on the defaults, suitable sheet layouts can also be created at Prinect Signa Station and made available so that the assignment of pages to optimized layouts can be automated to a great extent just like the other steps.

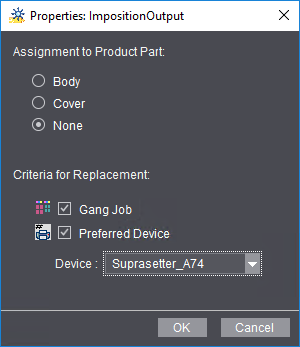

You can assign different properties to the various template placeholders in a smart template:

Assignment to Product Part

•Body

•Cover

•None

You can assign the template placeholders to product parts (body, cover) using these properties.

Criteria for Replacement

•Gang Job

•Approval

You can assign the template placeholders to gang jobs or an approval workflow using these properties.

You assign the properties for each template placeholder in the open smart template window that displays with the "Properties" context menu:

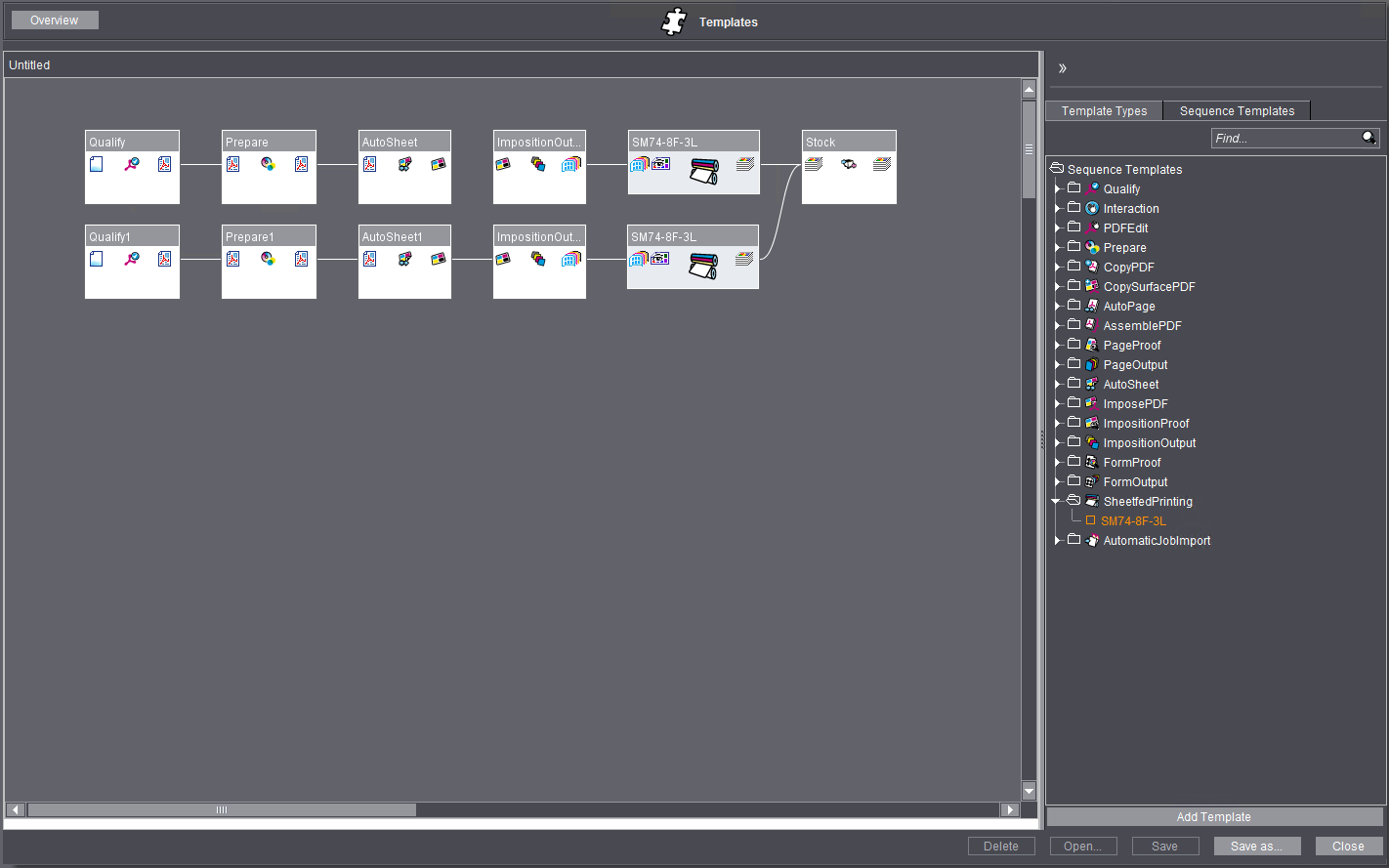

You can define different process routes for cover and body in smart templates, taking into account the special requirements of an automated web-to-print workflow. This means, for example, you can define a four-page color print on hardcover printing material for the "Cover" product part, and you can output the 64-page content only in black on different printing material. In finishing, the printed sheets are merged again to one overall product.

In this example, two template placeholders will be added to the smart template for each step up to printing (2x Qualify, 2x Prepare, etc.), whereas only one template placeholder will be added for each of the finishing steps. The product part property "Cover" and "Body" will be each assigned once to all of the double template placeholders. The finishing template placeholders will not be assigned a product part property.

In this way, it is also possible to set up a smart template for "hybrid jobs" where the cover is printed on a digital press and the body on an offset press.

In the example presented above, a four-page cover will be printed in a different print operation to the 64-page body. On an offset press, a press sheet may have more than four cover pages. You can define gang jobs to make optimal use of the available print format without having to assign the cover pages manually each time to a suitable sheet layout. In a gang job, the pages are buffered (in a "gang job pool") until all of the suitable sheet layout can be filled with pages. Only then are the pages assigned to the layout and processing of the sheet continues and it is output. Depending on the volume of the body, you can of course define gang jobs for this part as well, for example, for postcards, etc.

By doing this, gang jobs assist you in utilizing the areas on the press sheets optimally in an automated workflow.