The user interface of the Planning Assistant is structured as follows, going from top to bottom:

•View pane for the icons of the planning steps.

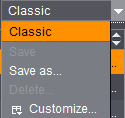

•Customization of the columns

You can add the columns you need or deselect them. You can save the column set under a new name.

Middle part:

View pane for the operations and for parameters that were entered or calculated as far as this planning step.

Operation is dimmed

There may be several reasons why an operation is dimmed:

•The operation was delegated, in other words, it is running in a different job.

•The machine is running the operation, preventing rescheduling.

Bottom part: Input Panel

Information for the binding, folding, gluing folding carton, cutting, die-cutting, press, printing material operations:

•"Duration" display:

The MIS is the "master" if the times are taken from the MIS. Setup time and production time are then calculated using the times stored in the MIS.

If times are not taken from the MIS, setup time and production time are calculated using the machine-related parameters filed in the Central Device Manager (CDM).

•"Quantity" display and input box:

·In the Planning Assistant, all the quantities are calculated based on the delivery quantity entered in the "Delivery" planning step. In the other planning steps, the quantities will appear as read-only where possible. For that reason, the box is normally locked. In exceptional cases, it may be necessary to edit the box. You can unlock the box with "Ctrl + Shift + E".

The following is applicable for the selected operation: The amount to be produced for this operation is calculated from the shown amount plus allowance. The amount calculated this way is the output variable for calculation of the amount(s) in the next operation.

Example: In the "Delivery" step, enter '1000' for the "delivery quantity". As a result, the amount ("Quantity") in the "Binding" step is '1000'. Enter an "Allowance" of 15 for binding. This means that the amount to be bound is 1015. In the next planning step ("Sheet finishing"), a quantity of 1015 is the output variable for calculation of the folding sheet quantities.

•The waste depends on the machine used and is set by the machine data. It is transmitted by the MDS but can also be entered by the user.