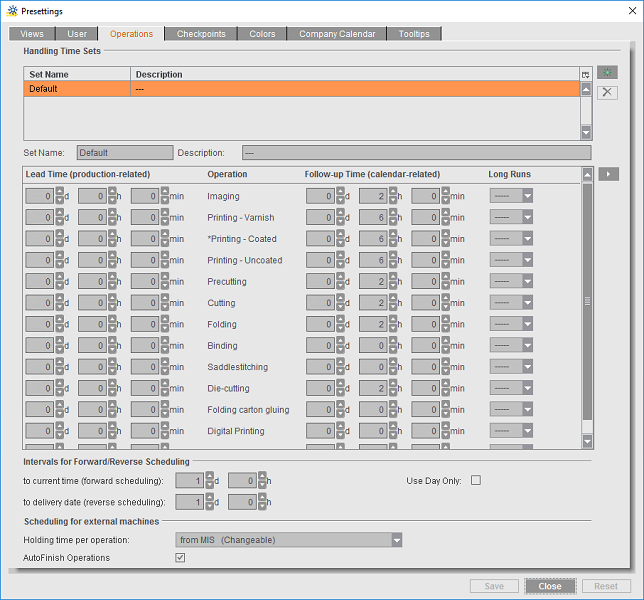

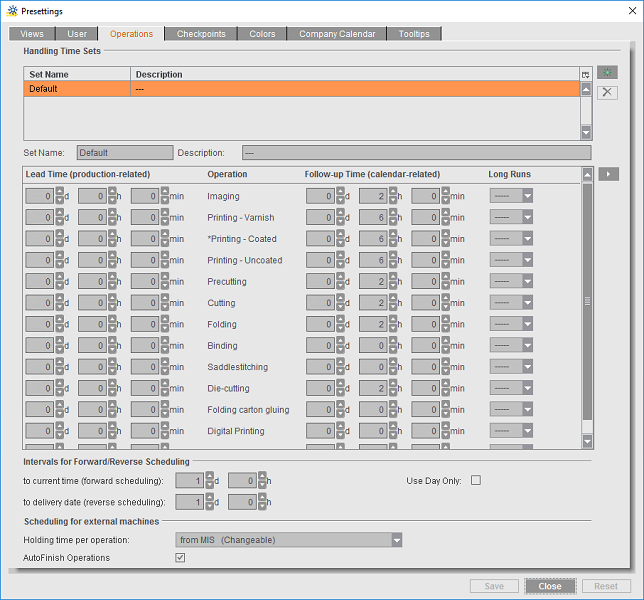

In the Prinect Scheduler, you can schedule operations in different ways. Because of the processes in production, it is important that suitable intervals for prepress, press and postpress operations are observed. You define the rules for compliance with these intervals in the "Operations" tab.

Note: You can predefine individual gaps before and after scheduled operations. In addition, you can also distinguish between 'production time' and 'real time'.

Example: The drying time of a sheet without varnish is much longer than the drying time with UV varnish. For that reason, you can set different intervals between cutting and folding.

In "Handling Time Sets" you define lead times and follow-up times for operations. The lead time is calculated from the production time only, non-productive times (outside a shift) are not considered. For the follow-up time, you can define an absolute time — drying is also possible outside a shift.

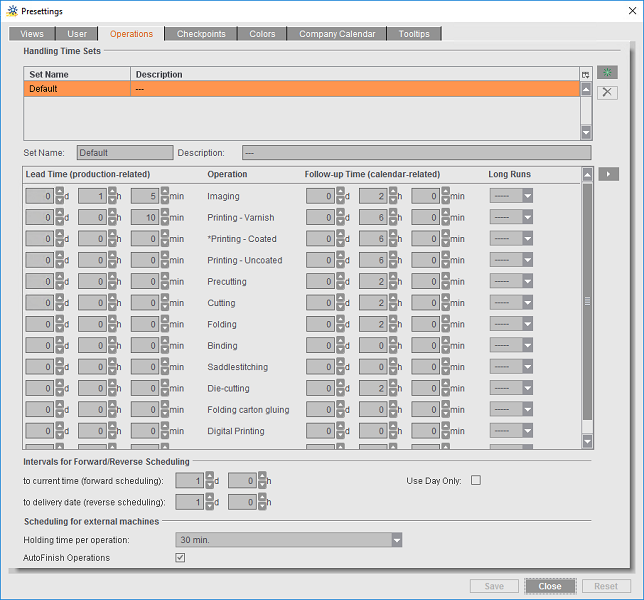

A "Default" handling time set is already set during installation. You can set the following parameters for the various operations:

•Lead Time (production-related):

In these boxes, enter the lead times for each of the operations, matching your production conditions.

•Follow-up Time (calendar-related):

This is where you enter the follow-up times matching your production conditions.

•Long Runs:

Operations may overlap in jobs that run for an extremely long period (high press run, e.g. with 30 hours printing). Such overlapping operations are highlighted in the planning board as red bars (warning). In such jobs, however, you may want to schedule the next step, for example, "Folding" after a printing period of six hours even though printing is not yet finished.

By setting a follow-up time (in hours) in the "Long Runs" column, you define a delayed start time for the next operation, referring to the time at which the preceding operation finishes. By setting a long run time, you disable the warning function for overlapping operations in the planning board.

The value "----" indicates that no delay is set (the "Long Runs" function is disabled).

Note: In the overall view, you can hide or view overlapping operations. When enabled, overlapping operations are marked with yellow arrows.

Video Tutorial: You can view more on this topic in the following video:

Prinect Scheduler - Easier to find overlapping operations

Example: A print operation starts on Monday at 10:00 and lasts till Monday at 20:00. Follow-up Time = 6 hours, Long Runs = 1 hour (1). The next operation is "Folding".

Without a time set for "Long Runs", the next operation will start on Tuesday at 2:00 (20:00 + 6:00 hours). The start of "Folding" is scheduled for 17:00. The schedule bars are red because the times for printing and folding overlap:

With a time of one hour set for "Long Runs", the next operation will start at 17:00 (10:00 + 6:00 hours + 1:00 hour). The schedule bars are not red because a "Long Runs" time was set:

You can define and save various "Handling Time Sets" for different production conditions (different production lines, with/without "Long Runs"). Proceed as follows:

1.Click the "Create new set" button.

2.In the "Set Name" box, type in the name for the new set, e.g. "ProductionLine1 Long Run". You may have to overwrite a default name (e.g. "Default").

3.If necessary, enter text in "Description", explaining the use of the set.

4.Enter the lead times, follow-up times and, when required, the long run times for all operations needed.

5.Confirm your configuration with "Save".

6.Repeat steps 1 thru 5 to create further sets.

7.To delete a set, mark the item concerned and click the "Remove handling times set" button.