"Layout settings" tab for Labelfire 340 (or DCS 340) presses

The options available in this tab are matched to the Labelfire 340 press. This means that options that do not suit this press model are not offered for selection. Other options are matched accordingly.

Note: For Labelfire 340 presses, the trimmed size is generally taken from the PDF.

"Substrate" list box

Selection of the substrate (web).

"Width" list box

You can select a web width for the substrate in this list box. If a substrate has several widths, you can specify the one you want by selecting it in this list box.

"Output Condition" list box

This is where you select the output condition defined for the paper used (see Machine setup using output conditions).

When you enable this option, you can import cutting dies as CFF2 files for labels and cartons and assign them to the 1ups found in the PDF files. You can select a CFF2 file in the file system of the Prinect server by clicking the "Browse" button. The 1ups in the PDF files are assigned automatically to the cutting dies. Combinations of 1ups and cutting dies can be arranged automatically on the substrate in different ways.

Prerequisite: To use CFF2 files, you must pay attention to the following general conditions:

·The 1ups in the PDF must match the cutting die in the CFF2 file with regard to the trim box shape, its size and orientation. If necessary, you can customize the data in the PDF Toolbox using "Assemble Pages".

·The CFF2 file may only have one shape. This can be used several times.

·The layout of the CFF2 file must have the same number of 1ups in every row. Likewise, each column must have the same number of 1ups.

Note: The trim boxes of the 1ups must fit into the cutting dies exactly. If necessary, you can correct this using the options in "1up position" by moving the 1up in relation to the cutting die.

You can set up the number of columns and rows on the subject and, if necessary, repeats using the "Columns" and "Rows" parameters and the "Repeat" option. See "Columns / Rows" options.

You can also set the horizontal subject offset to the printing material margin and positioning of the 1ups. See "Subject offset in X direction" option and "1up position" section.

"Use CFF2 File" is not enabled

If no CFF2 cutting die file is loaded, the parameters for defining the sheet layout differ compared to the workflow with cutting dies. See "Use CFF2 File" is enabled.

This is where you define the number of 1ups on the press sheet.

The "Repeat" option only has an effect if the "Rows" or "Columns" box contains a number equal to or greater than "2".

•"Rows" without "Repeat"

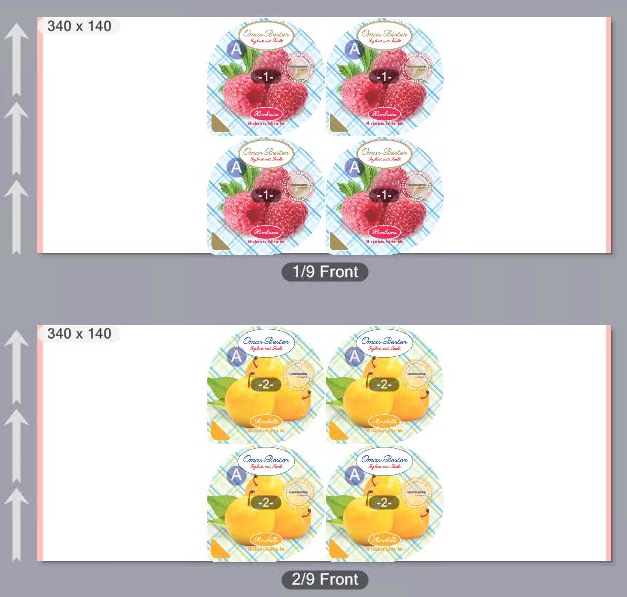

Enter a "1" in each case in the "Rows" and "Columns" boxes. The "Repeat" options are not enabled.

A different 1up is placed on each sheet:

Now enter a "2" in the "Rows" box.

Two different 1ups are now placed one below the other on a sheet:

•"Rows" with "Repeat"

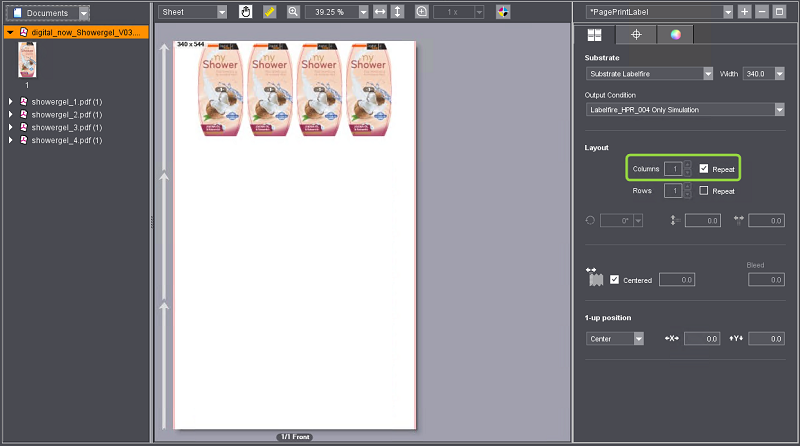

Enter a "2" in the "Rows" box. The "Repeat" option is enabled. A "1" is in the "Columns" box and "Repeat" is disabled in this case.

A 1up is placed repeatedly one below the other on each sheet:

•"Columns" with/without "Repeat"

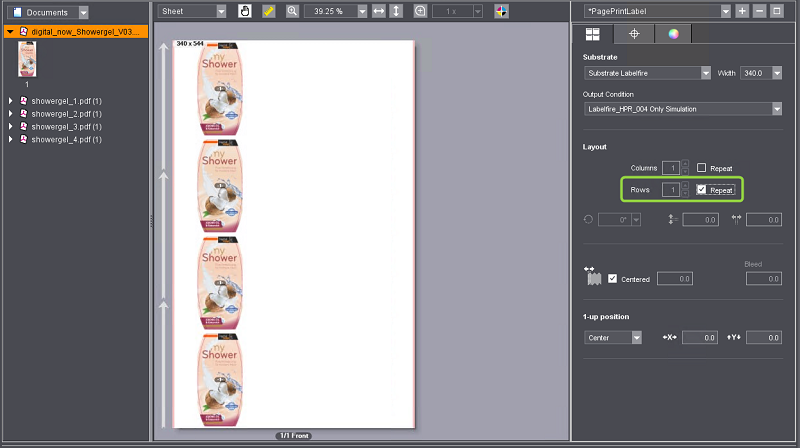

Enter a "2" in the "Columns" box. A "1" is in the "Rows" box and "Repeat" is disabled.

Two different 1ups are placed side by side on each sheet:

Enable "Repeat" beside "Columns".

Two 1ups of the same kind are placed side by side on each sheet:

•Rows and columns with Repeat.

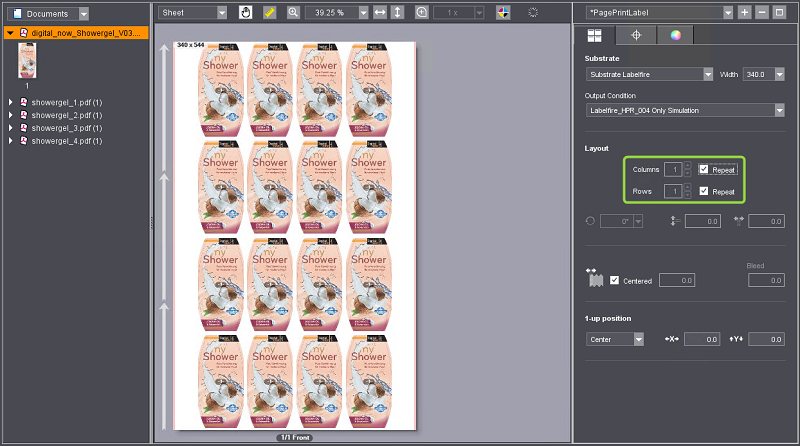

Enter a "2" in each case in the "Columns" and "Rows" boxes. Enable both "Repeat" options.

Four 1ups of the same kind are placed on each sheet.

"Columns / Rows" options for press sheets with CFF2 cutting dies

If the "Use CFF2 File" option is enabled and a label document and matching CFF2 cutting die file are open, you can use the "Repeat" options only in "Layout".

When you enable "Repeat" for columns, the substrate in horizontal direction is filled automatically with objects (e.g. labels), with as many objects placed as fit on the substrate width.

If only "Repeat" for rows is enabled, objects are placed likewise automatically in vertical direction.

The substrate is filled completely if both "Repeat" options are enabled.

Note: For example, you can have different labels that match the loaded cutting die arranged automatically. The PDF document must contain the labels or suitable PDF documents must be added to the job. Then create a page list with different labels and select the page list in the "Digital Printing" step. See "Display format" list box.

You can also link PDF/VT files to cutting dies, for example, for customized labels. The setting options for columns and rows as well as for repeats are not available for PDF/VT files. The sheet layout is automatically filled fully with the labels as specified in the PDF/VT defaults. You can change the order of the labels with the "Sort Order" option.

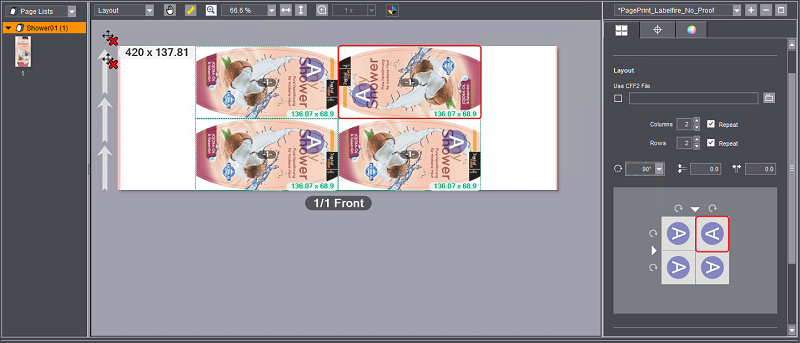

"Rotation" option (angle sign)

In this list box, you can set a rotation angle for all objects (pages, labels, folding sheets, cutting dies) placed on the surfaces. In doing so, the page content is rotated too.

Rotation angles 0°, 90°, 180° or 270° in clockwise direction are available.

Note: Orientation of the pages is tagged by "A" icons if you select the "Layout" view in the preview.

Custom folding sheet settings for spacing and rotation angles

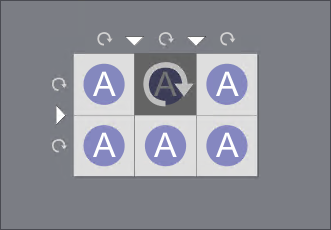

If a number greater than "1" is entered in the "Columns" and/or "Rows" boxes, a graphic displays in the lower part of the "Layout settings" tab where you can individually set the orientation of the single folding sheets and the spacing between the folding sheets.

When you click an object in the graphic, you can edit the orientation of this folding sheet. This orientation displays in the preview pane.

These rotations rotate the single objects on a surface.

In contrast to this, you set the orientation of all objects placed on a surface using the rotation angle settings from the list box.

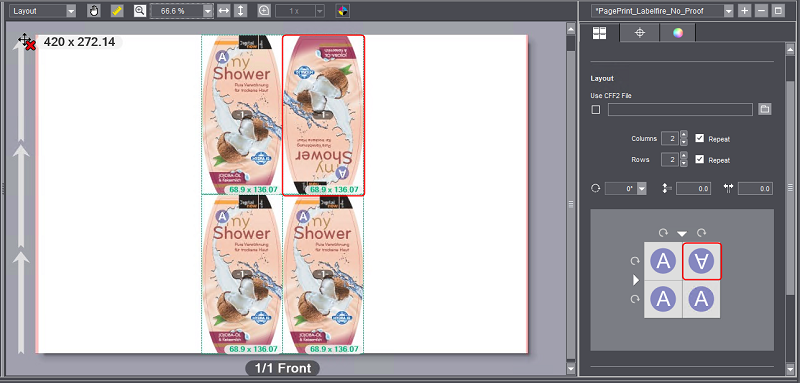

Example: A label is placed several times on a surface. Parameters: Columns = 2, Rows = 2, Repeat = On. The "Layout" preview is set.

Rotation angle setting = "0°", the top right object in the graphic is rotated:

Rotation angle setting "90°", the top right object in the graphic is rotated:

The whole arrangement of the labels is rotated by 90°, the top right label is rotated by 180° compared to the other labels as seen in the graphic.

The setting of the rotation angle in the list box rotates the entire arrangement of the objects on the press sheet. Rotations that you define by clicking in the graphic affect the rotation of single objects in relation to the other objects.

"Vertical/horizontal distance" options

Prerequisite: More than one page/folding sheet are placed in horizontal and/or vertical direction on the sheet layout.

With these options you can set up the vertical and/or horizontal gap between the pages or folding sheets.

|

|

Vertical spacing between folding sheets.

|

|

|

Horizontal spacing between folding sheets. |

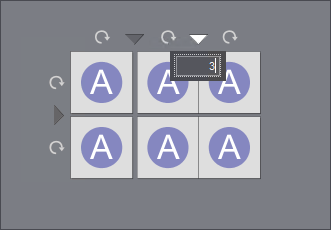

Set folding sheet spacing individually

If you wish to set the spacing between single folding sheets individually that is different to the vertical and horizontal spacing, you can do this in the preview graphic.

In the graphic, click the arrow for the separating line concerned and enter the spacing you want in the input box (in mm).

The spacing displays in the graphic and also in the preview window for the separating line. If needed, you can set other spacings.

Prerequisite: This option is available only if a job with PDF/VT documents (several data records) is being processed and if such a document is selected.

For some finishing processes, the sorting order of the data records in label printing must be defined in advance. You can select between the following sorting orders in the list box:

|

|

from top left to bottom right, horizontal |

|

|

from top right to bottom left, horizontal |

|

|

from top left to bottom right, vertical |

|

|

from bottom left to top right, vertical |

"Subject offset in X direction" option

|

|

Subject offset in X direction Use this parameter to set the left offset (in feed direction) of the printed content to the paper edge. Placement of the objects and display in the preview window are matched automatically and, consequently, the objects of the subject are positioned on the substrate as defined in the settings. |

Note: The grain direction of web material in the press is indicated by arrows in the preview. The page trim boxes of the subjects are shown when you select "Show > Boxes" in the context-sensitive menu in the layout section, visualizing the subject offset of the page trim boxes to the left substrate margin.

"Centered" option

The same offset to the printed content is set on both sides of the web substrate if you enable this option.

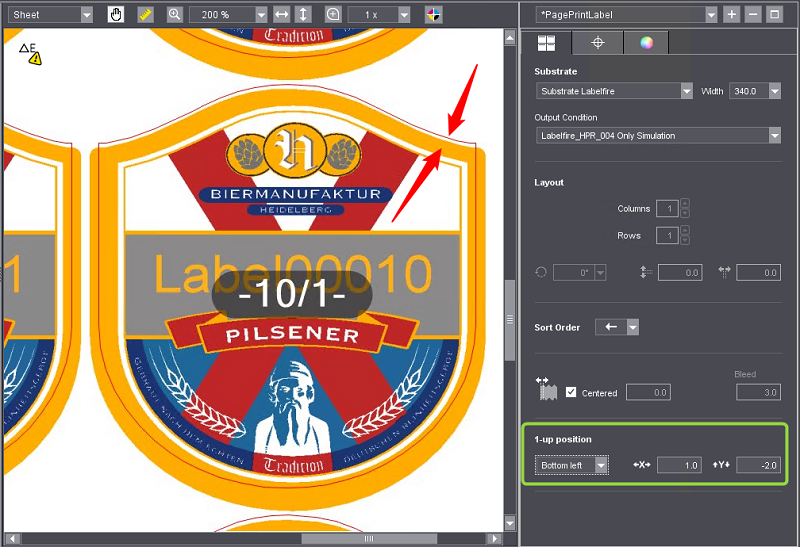

In this section, you can orientate the position of a 1up (e.g. a label) precisely compared to a cutting die. In this process, the trim box of the 1up is matched to the cutting die. Editing this is necessary only if the 1up positions do not exactly match the cutting dies. Proceed as follows:

1.Select the "Sheet" view in the preview and select a zoom factor that lets you detect the details of the objects accurately enough.

2.Select "Show > Cutting Die / Dimensioning" in the context menu above the preview pane.

3.Now in the list box in "1up position" select whether you wish to orientate the 1up centered or on the bottom left corner of the cutting die.

4.In the boxes for offset in X and Y direction, now enter offset values until the orientation of the 1ups exactly matches the center of the cutting die. You can also enter negative values in the boxes. The change displays in the preview when you change your input focus or hit the Tab key.

The High Performance Renderer (for Primefire / Labelfire) supports the printing of security tags. These contain special marks as prescreened CMYK images. These images must be printed as far as possible as they are in their original size.

These security tags work similar to QR codes and can be identified as the original print using special mobile device apps. A copy of the label would destroy the security feature.

You obtain a result that you can scan only if the security tags are printed without color management and using drop size 1.

Comments:

•The security tags can be placed on the label and marked with the Prinect PDF Toolbox.

•When the marked elements run through the Qualify sequence, they are detected and passed on to the High Performance Renderer without editing. The bitmaps for the security tags are generated there.

•This special handling of the security tags cannot be seen in the preview in the "Digital Printing" step but only in the TIFF output.

The following restrictions are valid:

•A security tag may be max. 20 x 20 mm.

•Several security tags can be placed on one page but they must not overlap.