Administration - Plate Pilot

Prerequisite: The following requirements must be met to operate the Plate Pilot:

·To generate the required planning data, an MIS (Management Information System) and/or the Prinect Scheduler must be available in the system environment.

·To use network signal lamps, such lamps must be installed and accessible in the network (WLAN) of the Prinect system environment.

With the Plate Pilot, it is possible to systematically put together printing plate stacks for just in time printing.

CTP devices

The Plate Pilot supports all imagesetters that are connected to the Prinect Manager directly via a Prinect Shooter 2 (Tiff-B export) or, if it is a third-party device, as an "external CTP device". See Add External CTP Device. When configuring CTP devices controlled via a Prinect Shooter 2, all the clusters containing this CTP device or the TIFF-B export devices have to be configured alike for the Plate Pilot. In other words, "Plate Pilot active" must be enabled, and the respective parameters must be configured.

Note: In "Administration > System", you can switch between manual operation and operation with the Plate Pilot, if needed, in the context menu in the "FormSetter" cluster view for directly connected CTP devices (not for TIFF-B outputs). See also Configure CTP devices for Plate Pilot or manual operation.

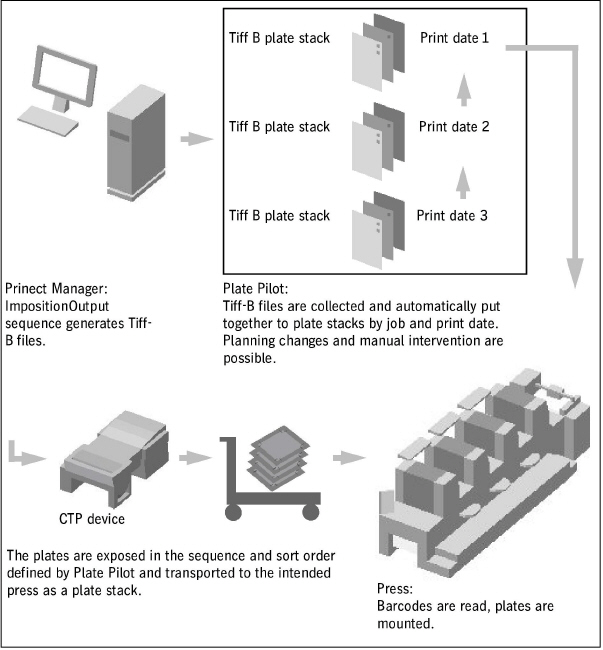

In a first step, the ImpositionOutput sequence generates the Tiff-B files required for exposure and collects them instead of forwarding them to the imagesetter immediately. When all the Tiff-B files belonging to a print job have been generated, they are put together to a "virtual plate stack" and sorted to match the print unit order. The assignment to a plate stack or the creation of a plate stack is based on the following criteria:

•the operations are scheduled for a specific press

•the print operations follow each other without gaps

•the maximum number of possible plates for the intended plate trolley is reached (a new plate stack is generated in this case)

•a minimum lead time prior to the scheduled print date has been reached, i.e. all plates must be exposed after the lead time has expired, and the plate trolley must have been transported to the press

•a minimum time offset to the scheduled print start has been reached.

The plates are exposed shortly before the scheduled date of the "Print" operation. The plates can then be transported to the press as a "real plate stack" on a plate trolley. Thanks to the sort order, the plates can be mounted into the print units one after the other, and printing can take place at the scheduled date.

Barcodes

Barcodes are printed on the plates and can be read at the press in order to automatically identify the plates. The barcodes are printed on the plates as marks and also contain operation information such as JobID, sheet, color, etc.

Note: These barcodes can also be used to control Plate Management Systems (Nela Plate Indexer).

Network signal lamps

The current state of CTP devices and plate trolleys can be indicated over a long distance with controllable signal lamps installed in the press room. In this way, you can easily detect that a plate trolley is completely filled and needs to be transported to the press or replaced with an empty trolley.

User Interface

The user interface of the "Plate Pilot" is part of the Prinect Portal (WEB UI). Configure the system-wide settings for the Plate Pilot in the Administration area of the Prinect Cockpit.

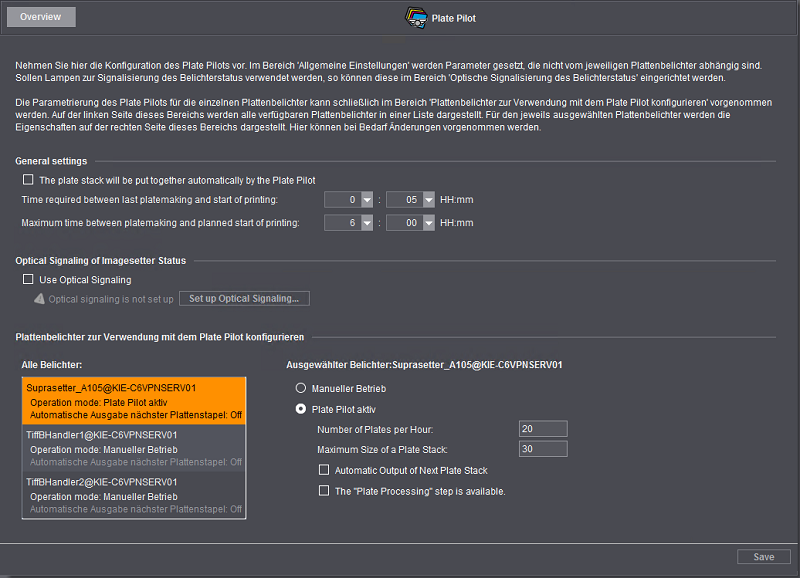

Configuration of the "Plate Pilot" Administration area

This is where you define settings that impact the general functionality of the Plate Pilot and not a particular CTP device.

Option "The plate stack will be put together automatically by the Plate Pilot"

Use this option to enable that plate stacks will be put together automatically. In this context, the plates belonging to a print job are arranged automatically in the correct sequence. At the press, the plates need only be taken off the stack and mounted in the respective print unit one by one.

Text box "Time required between last platemaking and start of printing"

This is where you enter the typical period of time required to transport the plate trolley to the press and to mount the plates into the print units. You may have to consider waiting periods that cannot be excluded at all times.

Text box "Maximum time between platemaking and planned start of printing"

This is where you enter the maximum period of time that may elapse between the end of platemaking and the print start (transport of plate stacks, waiting period, mounting of plates in the press).

These times are used for Plate Pilot scheduling and for calculating the order of plates in the plate stack.

"Optical Signaling of Imagesetter Status" group

Prerequisite: A network signal lamp must be present and accessible in the network system environment of the Prinect Server to be able to configure this area.

Although the Plate Pilot is capable of automatically putting together and exposing plate stacks, you cannot always identify a full plate trolley that must be replaced by an empty one in the press room right away. Software-controlled signal lamps can be connected to the Prinect Manager to indicate such a situation and also any errors from a greater distance. Signal lamps controllable via a network link (WLAN and/or LAN) are, for example, Philips Hue lamps, connected via a Philips Bridge. Depending on the input, these lamps can indicate various signals, e.g. red flashing in case of errors, or indicate that a plate trolley is full and needs to be replaced with an empty one. This must be done in due time to ensure the automatic workflow continues without jeopardizing scheduled deadlines.

Meaning of lamp signals:

|

Signal lamp |

Imagesetter |

Plate trolley |

Plate stacks |

Message |

|

|---|---|---|---|---|---|

|

|

Flashing red |

Error |

— |

— |

Imaging interrupted — action required |

|

|

Flashing yellow |

Warning |

— |

— |

Needs attention! |

|

|

Flashing blue |

Waiting |

Full |

Waiting |

Replace plate trolley! |

|

|

Flashing blue |

Waiting |

Empty |

Waiting |

Send plate stack to imagesetter for exposure |

|

|

Permanent blue |

Idle |

— |

Empty |

No plate stack to image |

|

|

Permanent green |

Imaging |

— |

— |

CTP device busy imaging |

|

|

Switched off |

Offline |

— |

— |

CTP device is switched off |

"Use Optical Signaling" option

Enable this option to use network lamps. This will enable the controls in this area.

Set up optical signaling

The "Set up Optical Signaling for Imaging Status" assistant opens when you use this button. There are three steps in this assistant:

•Select Connection Type

In the first step, you should try to have the lamp detected automatically in the network (option "Automatic Search in Network"). Usually, network lamps have specific properties by which they can be identified.

Note: You can prevent the automatic connection by blocking the respective port 1900 in Windows. In this case you can establish the connection manually. Determine the IP address required for Philips Hue lamps as follows:

a.Run a Windows command line (CMD).

b.Type "ping philips-hue".

c.The pertaining IP address will be displayed if the Bridge of the lamp can be accessed.

d.You can now use the address to establish the connection manually (option "Connect via IP Address"). For more information, please refer to the documentation of the lamp, or contact your system administrator.

Click "Next".

•Connect

This step will establish the connection of Prinect Manager with the lamp if it was detected. You can select the lamp you want if several lamps are available.

Click "Next" if the connection was established successfully.

•Connection Confirmation

This step will confirm the connection with the lamp and close the assistant.

"Configuration of Platesetters for Use with Plate Pilot" group

"All Imagesetters"

A separate item displays for each CTP device connected to the Prinect Manager (connected locally or via a Prinect Shooter). This is why the number of these items is variable, depending on the Prinect Manager configuration. When you click an imagesetter item, this displays on an orange background. The configuration elements beside it in "Selected Platesetter" refer to this imagesetter.

"Selected Platesetter"

This is where you define the settings for the selected imagesetter.

"Manual Operation" option

Enable this option if you wish to switch off the Plate Pilot for the selected imagesetter.

"Plate Pilot" option

The Plate Pilot is enabled for the selected imagesetter when you enable this option.

Number of Plates per Hour:

This is where you specify the number of plates the CTP device can expose per hour. We recommend specifying the maximum number of possible plates that, according to your experience, can be produced in the most adverse case (complex content) because imaging can vary depending on the content and this number is used for precise scheduling.

Note: When you are setting up an "external platesetter" in "Administration > System", the speed of platemaking is already defined. See Add External CTP Device. This value for the number of plates per hour is used as the default. You can change this value for special purposes related to the Plate Pilot.

Maximum Size of a Plate Stack

This is where you specify the maximum number of plates the CTP device or plate trolley can handle for a plate stack.

Option "Automatic Output of Next Plate Stack"

A new plate stack will be created automatically as soon as a plate stack is ready if this option is enabled. This option considers the Plate Pilot scheduling times.

Option "The ’Plate Processing’ step is available"

With this option, you set up the Plate Pilot management for the respective CTP device or CTP cluster.

When this option is enabled and when "Plate Processing" is enabled in the ImpositionOutput sequence of the CTP device involved, the imaged plates will be marked as "finished" only when the "Plate Processing" process is finished. See "Plate Processing" Option.