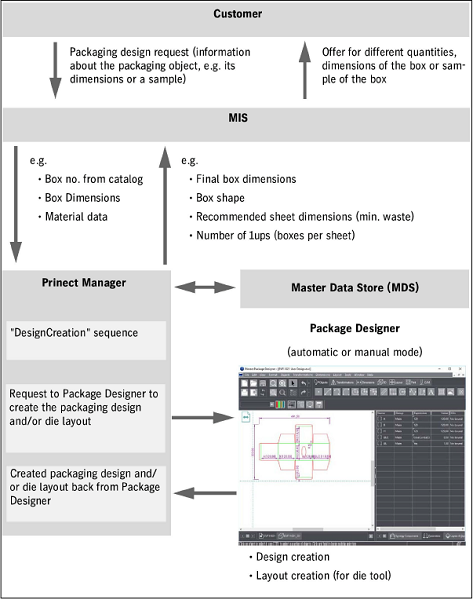

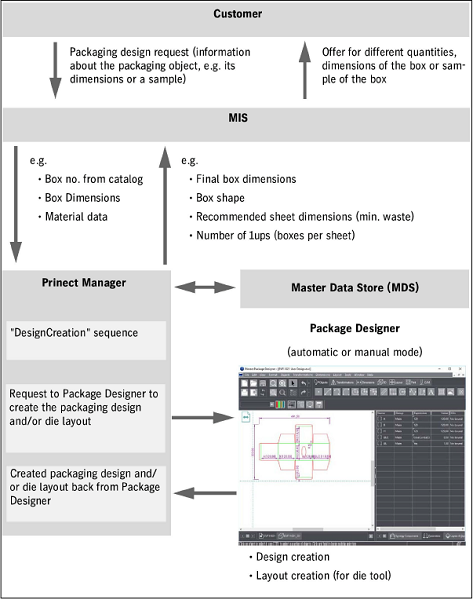

"DesignCreation" sequence in conjunction with the packaging workflow

For packaging printing, the Prinect Manager provides the option of editing special "preproduction jobs" (these are jobs without production of print products). These are jobs that assist users in designing a certain packaging and/or layout of a die tool. The jobs can be created manually in the Cockpit or they are created by a packaging MIS (e.g. CSG "Boxsoft"). The design or die layout is generated interactively or automatically with the Prinect Package Designer. In a packaging workflow, information that is needed for the single preproduction jobs (printing materials, box shapes, die layouts, dimensions, etc.) are exchanged between the various components (MIS, Package Designer, Integration Manager with Master Data Store) and used for editing the job. As a result, customers receive a quote on the cost of the packaging they want. This turns into a separate (production) job if customers should order quantities of the packaging later.

Planning is at the MIS in an automatic workflow. The data required for calculation of the shape and layout (e.g. box data (based on the dimensions of the packaging product), printing materials) are sent to the Prinect Manager and submitted to Package Designer. This can then automatically (i.e. without user intervention) create a shape and, if necessary, an optimized die layout. These results are then sent back to the Integration Manager preproduction job. Finally, the MIS received the data it needs to calculate an estimate.

A packaging job can be created in the Prinect Cockpit in a manual workflow, for example, if there is no packaging MIS. In this case, Package Designer can be started interactively and operated manually to be able to create the shape and, if necessary, the die layout. Package Designer receives the data defined in the preproduction job. Based on the data created by package Designer, users can calculate various offers manually and present them to customers.