Alignment of placed blocks on the cut lines

The dimensions of the assembly blocks/folding sheets are not always identical to the cutting edges. On the one hand, the geometry of the folding sheet is determined by the folding scheme and, as a result, can be different to the cut block. On the other, margins can be set around the 1ups in the product part template in the case of assembly blocks.

This is not a problem as long as the distances of the folding sheet/assembly block edges to the cut blocks are all the same because the common block edges of placement and the cut blocks then always stay on one line and are related.

However, when folding sheets and assembly blocks are mixed or different margins are set in the assembly blocks, then the block edges and cut lines have different distances, and the cut lines do not form any common edges. The result of this is that cutting is no longer optimal.

As of version 2019, such cases are included in optimization:

Folding sheets/assembly blocks with different margins without (left) and with cut optimization

If less 1ups can be placed on the sheet as a result of cut optimization, then utilization of the sheet has higher priority.

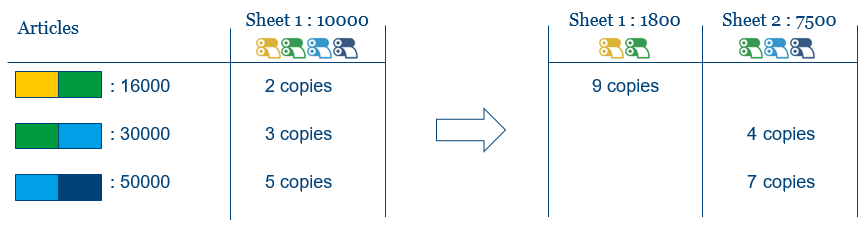

Single-sided and double-sided 1ups

Optimization includes the distribution of single-sided and double-sided 1ups to prevent a few double-sided 1ups from being scattered on the press sheets, in turn requiring a whole plate set for the back.

The impact of the function is greatest when the cost for separations is not specified with "0".

Optimization with "Include Separations" gives you only press sheets where the placed documents of a press sheet do not have more colors in total than available printing units. This makes it possible to avoid multiple runs. The report not only supplies the usual details but also a table listing the separations used, indicated by front and back.

The number of available printing units is defined in the Plate Template Editor. To use these values from the plate template, "Use Optimization Parameters from Plate Template" and also "Include Separations" must be enabled in the sheet optimization data.

You can enable the functionality at the following points:

•"Resources "> "Sheet Optimization Setup Editor"

•"Optimization" step "Advanced Settings > Sheet Optimization Setup"

The color list is filled with content in the "Job" step in the "Colors" tab already during the import of the input data for optimization. All colors that occur in the input data are listed. In the "Usage" and "Output as" columns, you can edit the properties of the colors. Colors whose "Usage" is defined as "Tool" or "Proof" are not included later in optimization.

When optimization starts with "Include Separations" enabled, the system checks whether there are documents in the input list for sheet optimization that have more colors on the front or back than printing units specified for the plate template concerned. If this is the case, an error message displays if no plate template is suitable or a warning if at least one plate template can be used for the data specified.

Product Part Search with ShapeID instead of Product Code

The Montage and Label/Packaging work modes merge when "Sheet Optimization without Layout Default" and "Sheet Optimization with Layout Default" are used. Because labels/packaging products are described only via a ShapeID and not via a ProductCode, Prinect Signa Station has to generate a ProductCode from the ShapeID. This process, with a product part template found as a result, is described below.

Sheet Optimization without Layout Default

The search for a product part runs based on the following scheme. The following conditions must be met in order to select this product part template:

•The product code entered in the product part template matches the "ShapeID_$$" string, with $$ corresponding to the ShapeID.

•The product part template is an assembly product part template and has loaded a CF2.

•The list item ShapeID matches the ShapeID of the product part template.

Normally, the full ProductCode (no wildcard) is then entered, e.g.

ProductCode="ShapeID_circle" for ShapeID=circle.

If the search was not successful, it continues with the following conditions:

•The product code entered in the product part template matches the "ShapeID_$$" string, with $$ corresponding to the ShapeID.

•The product part template is an assembly product part template and has not loaded a CF2.

Normally, the product part template is then a placeholder for all CF2-based assembly blocks (a restricted "Assembly Block" product part template is enough). The product code can then be "ShapeID_*".

Caution: In this scenario, the content cannot be clipped along the dieline. Also, no information about the ShapeID is written to the output product.

If the search was still not successful, it continues with the conditions below. But only if it is NOT a list item from "industrial ganging" (this includes gang pool processing, gang job and Prinect Business Manager gang job).

Reason: In industrial ganging, the product code search must be successful; the assembly product part template set in the job must not be used.

•The currently set assembly product part template for CF2 is used.

•The assembly product part template has loaded a CF2.

•The list item ShapeID matches the ShapeID of the product part template.

Normally, the full product code is then entered, e.g. ProductCode="ShapeID_circle" for ShapeID=circle.

Note: This scenario is very specific and is only useful if you are working with identical list item ShapeIDs.

If the search was still not successful, it will succeed as follows:

•The currently set assembly product part template for CF2 is used.

•The assembly product part template has not loaded a CF2.

Normally, the product part template is then a placeholder for all CF2-based assembly blocks (a restricted "Assembly Block" product part template is enough).

Attention: In this scenario, the content cannot be clipped along the dieline. Also, no information about the ShapeID is written to the output product.

Sheet Optimization with Layout Default:

The system searches for product part templates in the cluster. If the following conditions are met, this product part template wins.

•The product code matches "ShapeID_$$", with $$ corresponding to the ShapeID.

•The assembly product part template has loaded a CF2.

•The list item ShapeID matches the ShapeID of the product part template.

Normally, the full product code is then entered, e.g. ProductCode="ShapeID_circle" for ShapeID=circle.

The list item page size is not checked further with that of the product part templates in the cluster.

If the search was not successful, it continues with the following conditions:

•The product code matches "ShapeID_$$", with $$ corresponding to the ShapeID.

•The assembly product part template has not loaded any CF2.

•The list item page size is compared with the page size of the product part template in the cluster.

Normally, the product part template is then a placeholder for all CF2-based assembly blocks (a restricted "Assembly Block" product part template is enough). The product code can then be "ShapeID_*".

Caution: In this scenario, the content cannot be clipped along the dieline. Also, no information about the ShapeID is written to the output product.

Note: It is not possible to use "Sheet Optimization with Layout Default" without using the product code (at least "ShapeID_*").