Linearization and Process Calibration in the Printing Process

Linearization comprises the output process up to imaging of the plates or film (see diagram above).

The input tonal values from the PDF/PS are to be linear to the output tonal values on plate or film. The dot percentages are measured on the plate or film.

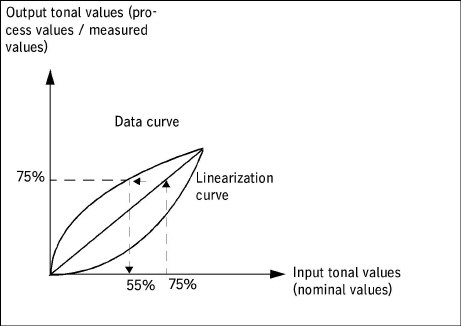

The principle of linearization is similar to that of process calibration, only that the nominal values are linear. An example is used to illustrate this in the diagram below. The nominal value of 75% is replaced by the nominal value of 55% in order to obtain an output tonal value of 75%. The linearization curve is produced by mirroring the data curve along its diagonal.

Diagram showing example of linearization:

Process calibration comprises the output process up to printing to the printing material, see the Linearization and Process Calibration in the Printing Process.

See also Principle of Calibration Based on Process Calibration .

The actual dot percentage on the printing material for a nominal value of 50% is to be 65%, for example, according to the process curve. However, this tonal value is not achieved at the nominal value of 50% but at 47% as shown in the data curve. For that reason, the calibration curve assigns the tonal value of 47% to the input tonal value of 50%.

Diagram showing example of process calibration: