There are two types of dot gain:

When a screen dot passes from film to plate and rubber blanket onto the printing stock, its geometric size and, accordingly, its tonal value can change because of various influences.

•optical dot gain. See Optical dot gain.

The perceptible hue on the press sheet, that is, the actual dot percentage, materializes both through the process-related and the optical dot gain.

Dot gain is the absolute and not the relative gain in dot percentage. For example, the overall gain is 17% if a 50% hue in the original really has a 67% dot percentage on the press sheet.

The process-related dot gain refers to a change in the geometric dot size during a processing step. The geometric dot size can change at three points in the process:

•at the exposure and development of the film or plate

•at the contact exposure and development of the plate in one film run

•at the printing process on the printing machine

Dot size might slightly change during exposure to plate (directly or from film). The contact exposure of a negative film normally results in an increase of tonal value, whereas the contact exposure of a positive film usually reduces the tonal value.

The tonal value changes at the press during transfer of the dot from the plate to the printing material via the rubber blanket. The ink, paper, rubber blanket and printing plate are influencing factors. For example, too much ink can be applied or the printing material does not absorb the ink well. In this case, the ink is pressed apart, making the geometric dot size bigger.

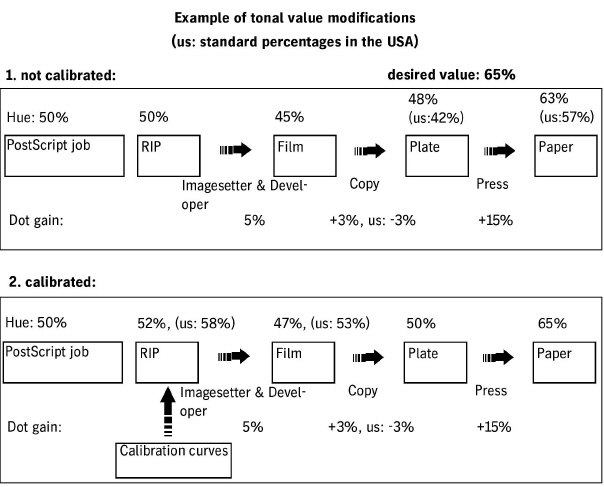

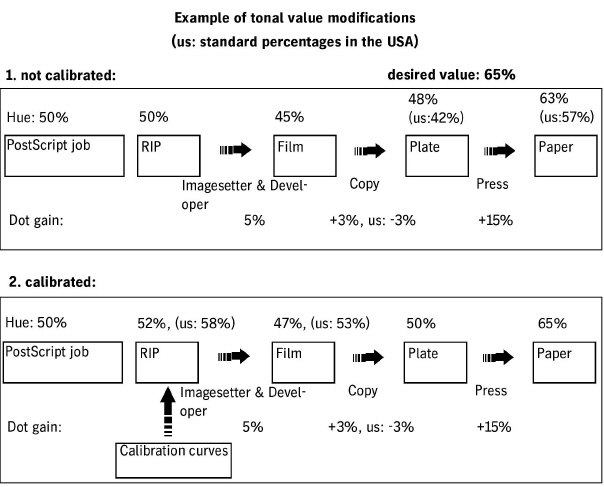

The illustration shown above displays typical tonal value modifications. In this example, the total dot gain (from the PDF hue to the output hue of the press sheet) is 15% and the actual dot percentage on the press sheet is 65% (based on a 50% PDF hue).