In the Operation report "Summary" you see the quality evaluation of a selected operation according to the preset print standard. The selected OK sheet is compared with the wet ink set of the print standard and assessed in relation to the tolerance specified in the print standard. In addition, all subsequent measurements are compared with the OK sheet during the production run and assessed in relation to the variance specified in the print standard.

Other than "Job quality", the "Summary" report contains the real measured values.

Note: You can change the preset print standard in the Presettings of Analyze Point. See Presettings - quality reports.

Requirements

See Requirements.

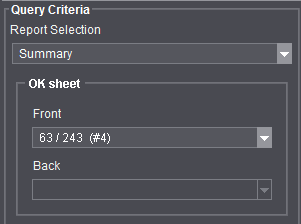

Query Criteria

This lets you select the measuring sheet to be used as the OK sheet for assessing the quality. You can select one measuring sheet each if the operation comprises front and back.

The OK sheet selected here is relevant for the following:

•In "Job quality" and the operation report "Summary", the OK sheet is assessed according to the preset print standard.

•For production run checks, "Job quality" and the operation report "Summary" only use those measuring sheets printed after the selected OK sheet.

By default, the following press sheet is selected as the OK sheet:

•The following applies to Prinect Axis Control and Prinect Inpress Control:

Up to Prinect 2017, the first sheet after you switch on the good sheet counter is selected. As of Prinect 2017 and Prinect Press Center version 15B.02, the press sheet that the user set as the OK sheet on the colorimeter is selected. If none is set, the first sheet after you switch on the good sheet counter is selected.

•For Prinect Image Control:

The first sheet after you switch on the good sheet counter is selected.

Meaning of OK sheet values on display:

•The first value indicates the number of good sheets printed at the time of measurement.

•The second value indicates the number of all press sheets (good sheets and waste) printed at the time of measurement.

•The value in brackets stands for the measurement number.

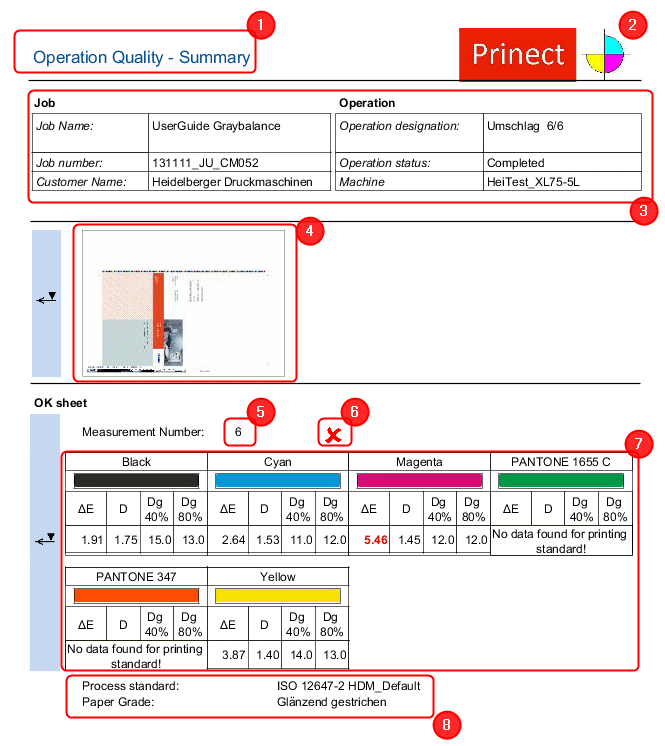

Operation Quality "Summary"

Report title (1)

The logo you selected (2). See Logo.

Header data (3):

•Information regarding the job

•Information regarding the operation

Thumbnails for front and back (4)

OK sheet:

•Measurement Number (5):

Number of the measuring sheet used for quality evaluation. By default, the first measuring sheet is selected. You can use the query criterion "OK sheet" in the left navigation pane to manually select another OK sheet.

•Evaluation of the OK sheet (6):

Evaluation of the OK sheet by status icon (see Status icons). For evaluation, the OK sheet is compared with the value of the wet ink set specified in the print standard.

Note: Only those measured values recorded in this table are used for evaluation. The result is always "OK" if there are no measured values, for example for dot gain (dash "-" in the cell).

•Table with measurement results for each color (7):

Measurement results for Delta E, density and dot gain for each color of the OK sheet.

·Red measured value

This value exceeds the permissible tolerance specified in the selected print standard.

·Dash "-" in the measurement:

The operator of the colorimeter did not measure this value.

·No Lab data found in measurements!:

The protocol does not contain the required measuring values. Cause: Color measuring was performed with an incompatible software version. See Requirements.

·No data found for printing standard!:

The print standard does not contain any color or paper grade values.

•Measuring conditions (8):

Used print standard and paper grade

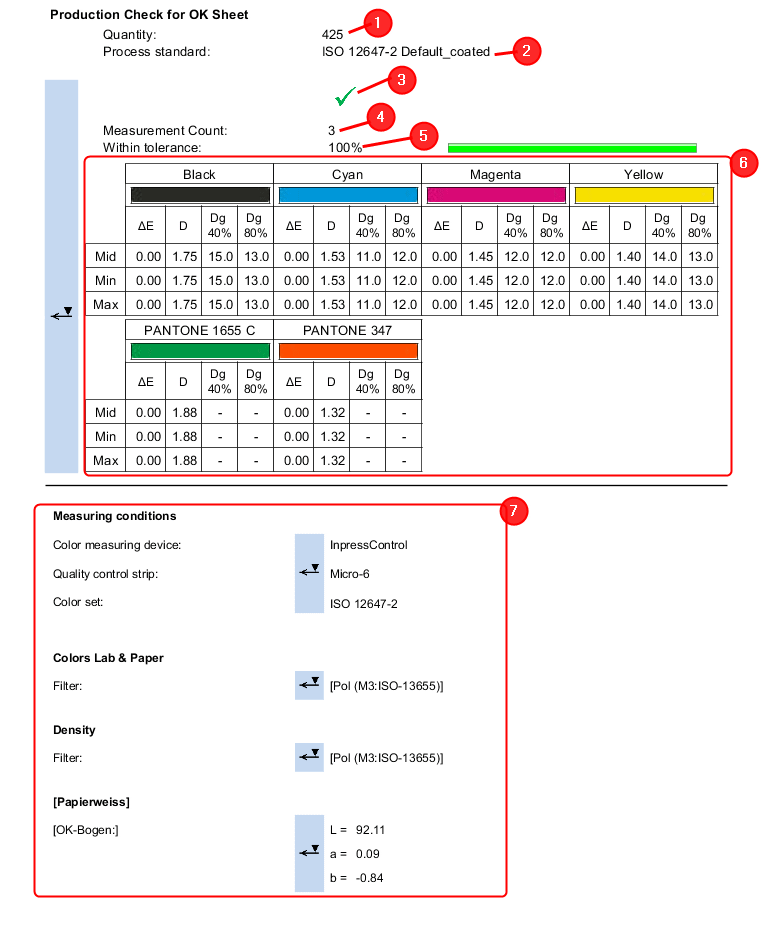

Production Check for OK Sheet:

•Quantity (1):

Total number of OK sheets

•Process standard (2):

Used print standard

•Evaluation of the production run (3):

Evaluation of the production run by status icon (see Status icons). The measurements during good production (good sheet counter ON) are compared with the OK sheet and assessed. The status icon in the "Print Run Quality" column also gives you a fast overview of the production evaluation of all operations. See Display of the print run quality .

Note: Only those measured values recorded in this table are used for evaluation. The result is always "OK" if there are no measured values, for example for dot gain (dash "-" in the cell).

•Number of measurements (4):

Number of measuring sheets considered for the production run check. Only those measurements performed after the selected OK sheet are considered.

•Within the tolerance (5):

Number of measurements lying within the tolerance according to the print standard when compared to the OK sheet. The production run is assessed "OK" if at least 68% is within the tolerance.

•Table with measurement results for each color (6):

Average (Mid), minimum (Min) and maximum (Max) for Delta E (ΔE), density (D) and dot gain (TWZ) of each measured color.

·Average (Mid)

Average of all measured values of measured sheets

·Minimum (Min) and maximum (Max)

Smallest or greatest average value of all measured sheets.

For calculation, the average of each measuring sheet is determined first. The following example for density will illustrate this:

|

Measuring sheet |

Average density |

|---|---|

|

Measuring sheet 1 |

1.73 |

|

Measuring sheet 2 |

1.63 |

|

Measuring sheet 3 |

1.83 |

The average density of measuring sheet 2 (1.63) in this example is the minimum, and that of measuring sheet 3 (1.83) is the maximum.

·Red measured value

This value exceeds the permissible tolerance specified in the selected print standard.

·Dash "-" in the measurement:

The operator of the colorimeter did not measure this value.

·No Lab data found in measurements!:

The protocol does not contain the required measuring values. Cause: Color measuring was performed with an incompatible software version. See Requirements.

·No data found for printing standard!:

The print standard does not contain any color or paper grade values.

Measuring conditions (7)