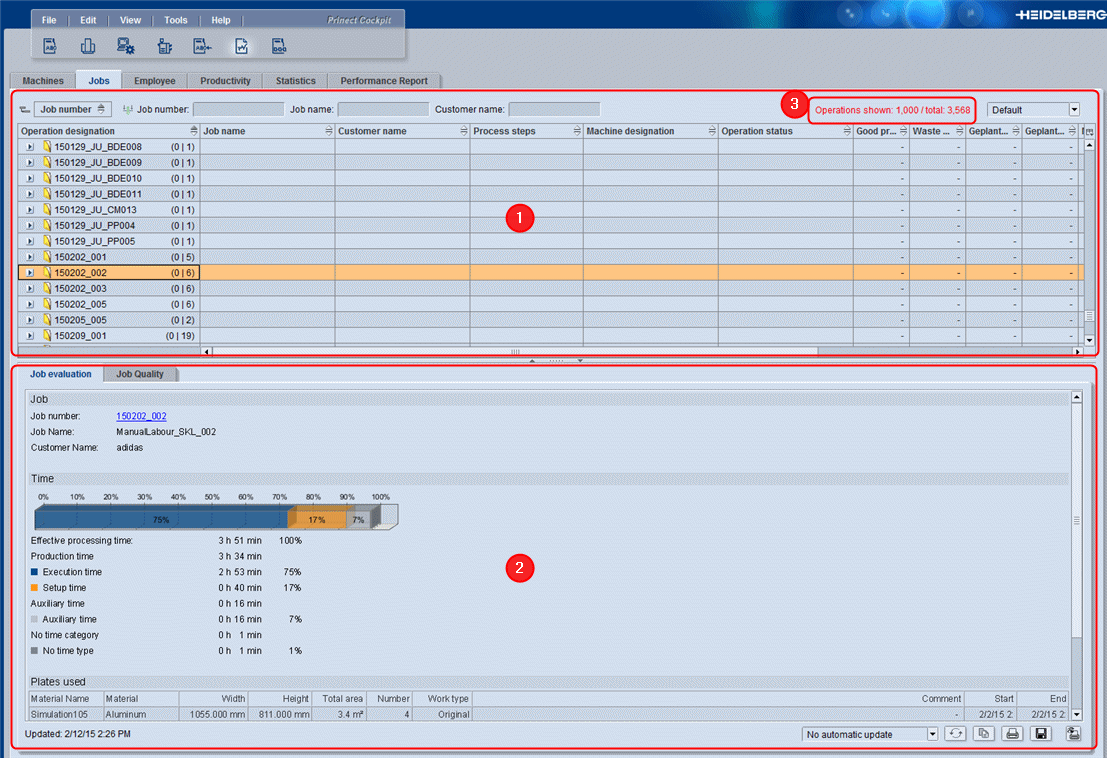

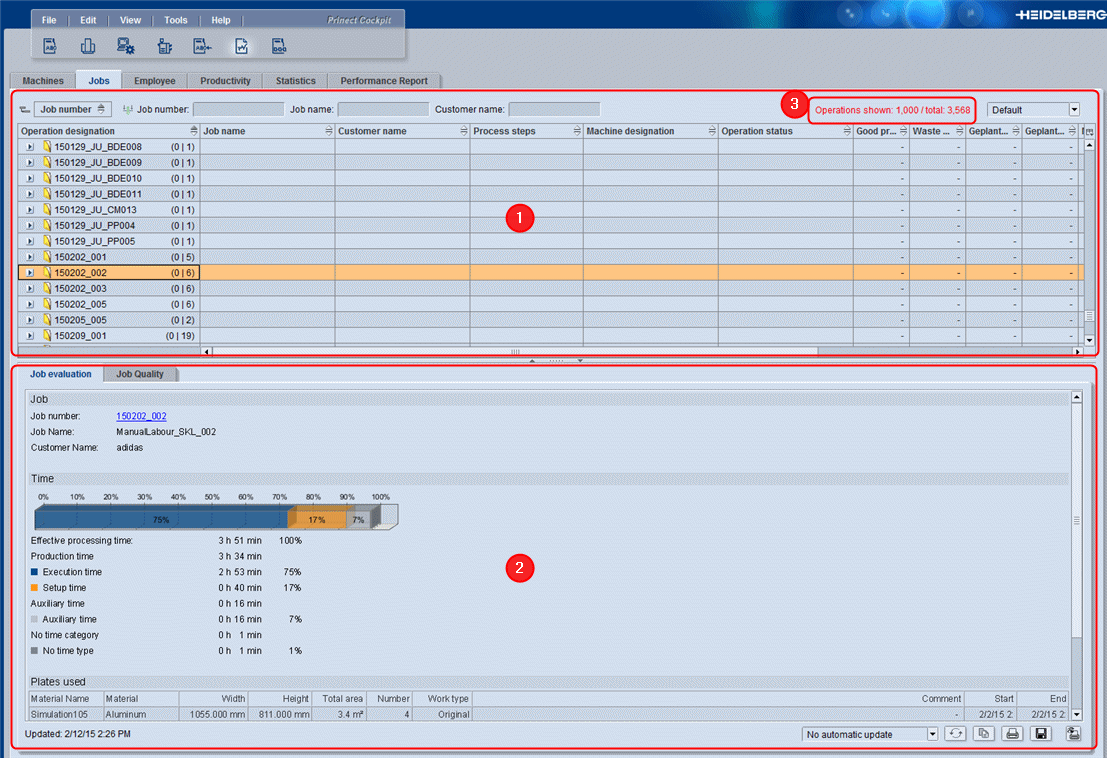

The job view gives you a quick overview of your jobs (1) as well as a job evaluation for each job (2). A maximum of 1000 operations display for fast loading times. If there are more operations on the whole in the database, you will see a message about this (3). Unprocessed operations are not recorded by Analyze Point.

Maximum 1000 operations displayed (3)

You can view jobs with a maximum of the last 1000 operations. If there are more than 1000 operations, a message showing you the total number of available operations displays at the bottom left. You can also display jobs that were not shown without a filter if you use filters on your jobs (for example, filter for "Heidelberg" jobs).

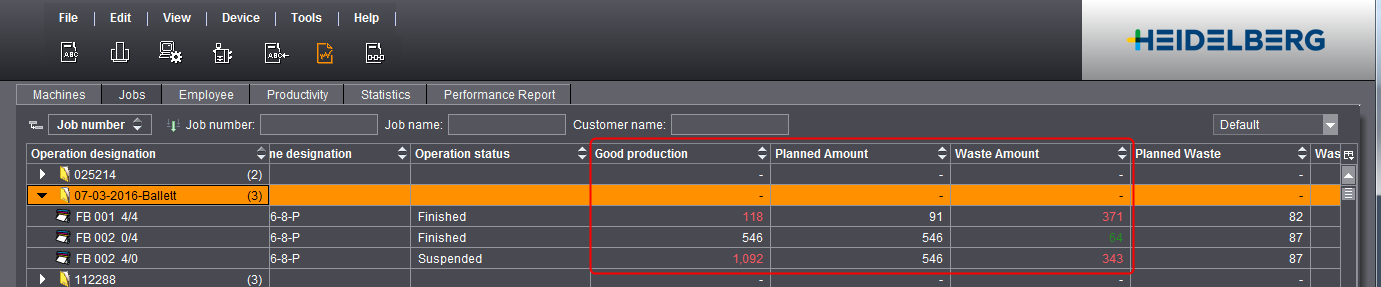

Colors highlighting differences in quantity

Prerequisite: By default, this function is disabled. Contact your service technician if you wish to enable it. The differences display in Analyze Point only if planned quantities were sent beforehand by an MIS or were entered in the Planning Assistant.

The screenshot shows the number of waste sheets in green. This means, less waste sheets than scheduled were produced. The values for number of waste sheets and good production of two operations are red. This means, more waste and more good production sheets than scheduled were produced.

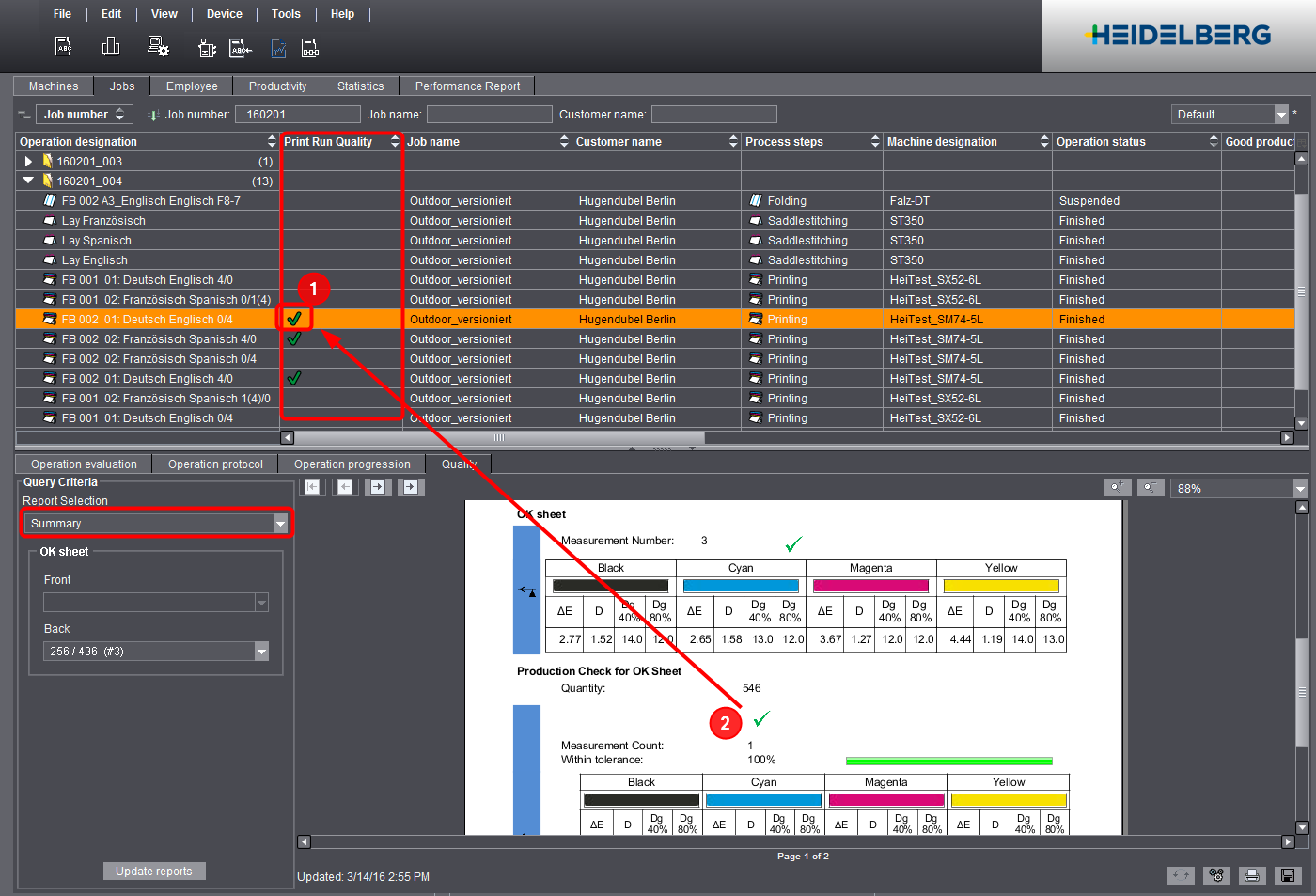

Display of the print run quality

The "Print Run Quality" column displays the status of the production run check to give you a fast check of the ink quality of an operation (1). This is the same status that displays in the "Summary" operation quality (2). See "Summary" Operation Report.

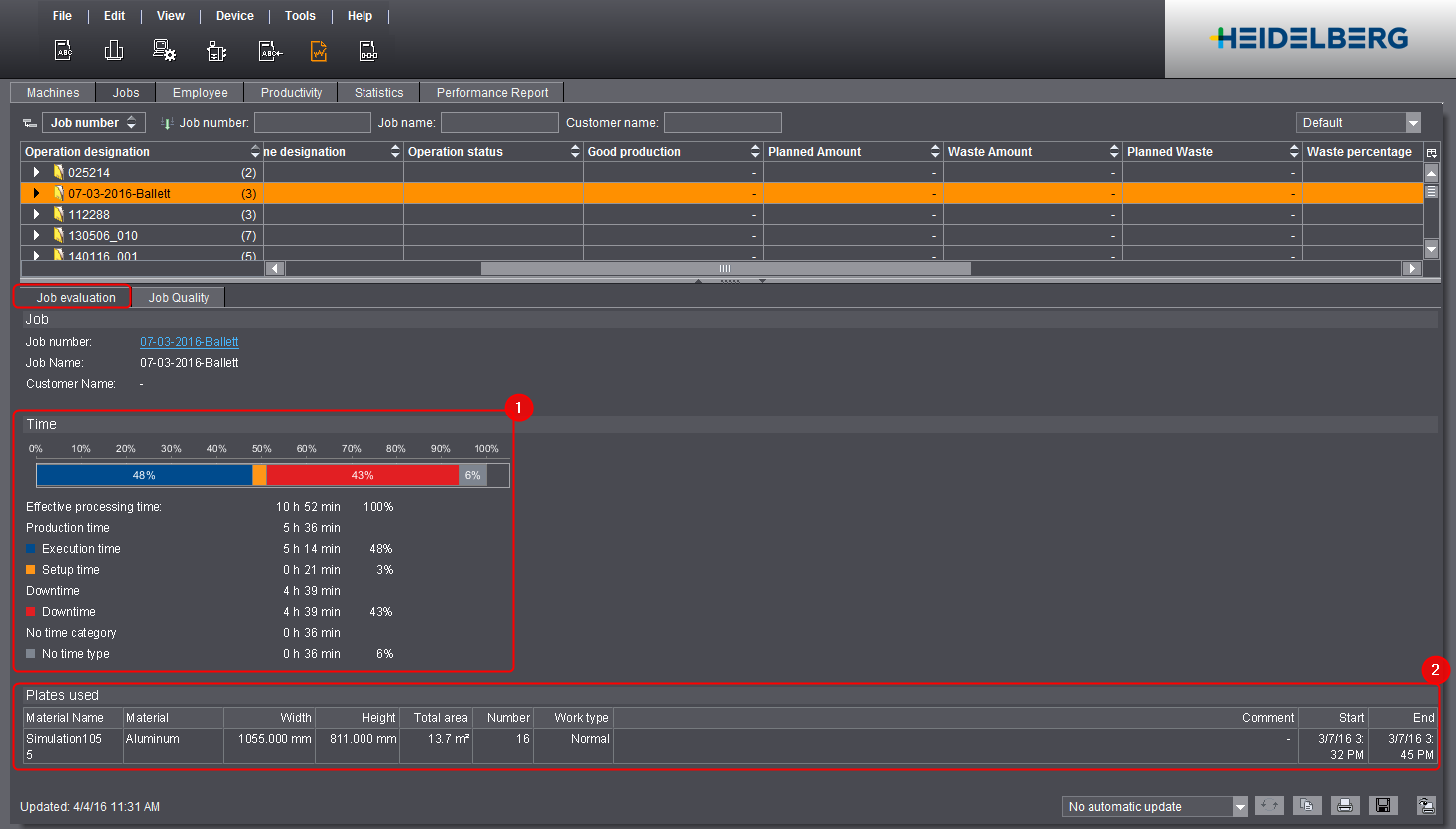

The "Job evaluation" tab shows you job data (job number, job name and customer name), times and material consumption for the selected job. You can find a detailed description of the times in Time (4).

Time (1)

The bar chart shows the percentage ratios of the production times. Here, the individual production times (percentages) always refer to the effective working time.

The effective processing time is always 100% (effective processing time = sum of all times in which an operation in the job was loaded on a machine). The absolute and percentage production times display again separately below the bar chart.

The classification and capture of times depend on how you have configured the time categories and time types in the Device Configuration. See Time Category.

The material consumption listed depends on the job. This includes:

•Plates used

Shows the number of imaged plates.

•Paper Consumption

Paper consumption is recorded through the material consumption message on the machine. In this process, the material number entered on the machine must match the article number of the planned paper. You can follow which paper is planned for an operation in the "Press" step (see "Materials" Tab). Paper is recorded as "Other Material Consumption" if a different article number is entered.

•Clicks

Shows the number of clicks recorded for your connected digital press. The billing category depends on the machine.

•Other Material Consumption

Shows all other material recorded that cannot be assigned to plates, paper or clicks. This also includes paper that is known in the MDS but not assigned to the job.

Job quality offers a fast overview of the print quality of all print operations of the selected job in relation to the present print standard. You can use this report to present your customer a comprehensive evaluation of the color quality.

Job quality shows you the following evaluations:

•The OK sheet is compared with the wet ink set of the measuring device and assessed with regard to the deviations to the print standard.

•The production run sheets are compared with the OK sheet and assessed with regard to the deviations to the print standard.

•The job is given a comprehensive quality evaluation based on the OK sheet and production run sheet evaluation.

The operation report "Summary" offers a more detailed evaluation of all operations. See "Summary" Operation Report.

Note: You can change the preset print standard in the Presettings of Analyze Point. See Presettings - quality reports.

To display the job quality, the following software prerequisites for the measuring devices apply:

•Prinect Image Control I:

Not supported

•Prinect Image Control II:

I13A and later

•Prinect Axis Control I:

Not supported.

•Prinect Axis Control II:

S12B and later

•Prinect Inpress Control:

S12B and later

Additional prerequisites for Prinect Axis Control II and Prinect Inpress Control

To display quality reports, the following prerequisites must be met:

•The option "Enable import of color data" must be activated and an output directory defined in the Prinect Pressroom Manager/Prinect Integration Manager for every created press that has a Prinect Inpress Control / Prinect Axis Control II.

•The color measurement output directory must be defined on the Prinect Press Center control station. The source directory must be identical to the color measurement target directory of the created press.

For in-depth instructions on how to connect Prinect Axis Control II, see Connecting Prinect Axis Control II.

For in-depth instructions on how to connect Prinect Inpress Control, see Connect Prinect Inpress Control.

•At the Prinect Press Center, you must load the job from the Workplace Interface of the connected Prinect Pressroom Manager/Prinect Integration Manager.

Note: No color data is sent to Analyze Point if the job is loaded from the local memory of the machine.

Additional prerequisites for Prinect Image Control

To display quality reports, the following prerequisites must be met:

•Set up a "Prinect Image Control" as PPFOut device in Prinect Pressroom Manager/Prinect Integration Manager. You define the output folder for the color data here.

•Set up the press you want to connect to Prinect Image Control in the Central Device Manager.

•Connect the press to Prinect Image Control and import the press parameters.

•In Prinect Image Control, you must define the folder for the Analyze Point data. The folder must be identical to the color data output folder you created when setting up the PPFOut device.

For in-depth instructions on how to connect Prinect Image Control, see Connecting Prinect Image Control.

Storage period of the color reports

If measured data should not display despite the latest software versions, it is possible that they were already deleted from Analyze Point. See Storage Period of Reports.

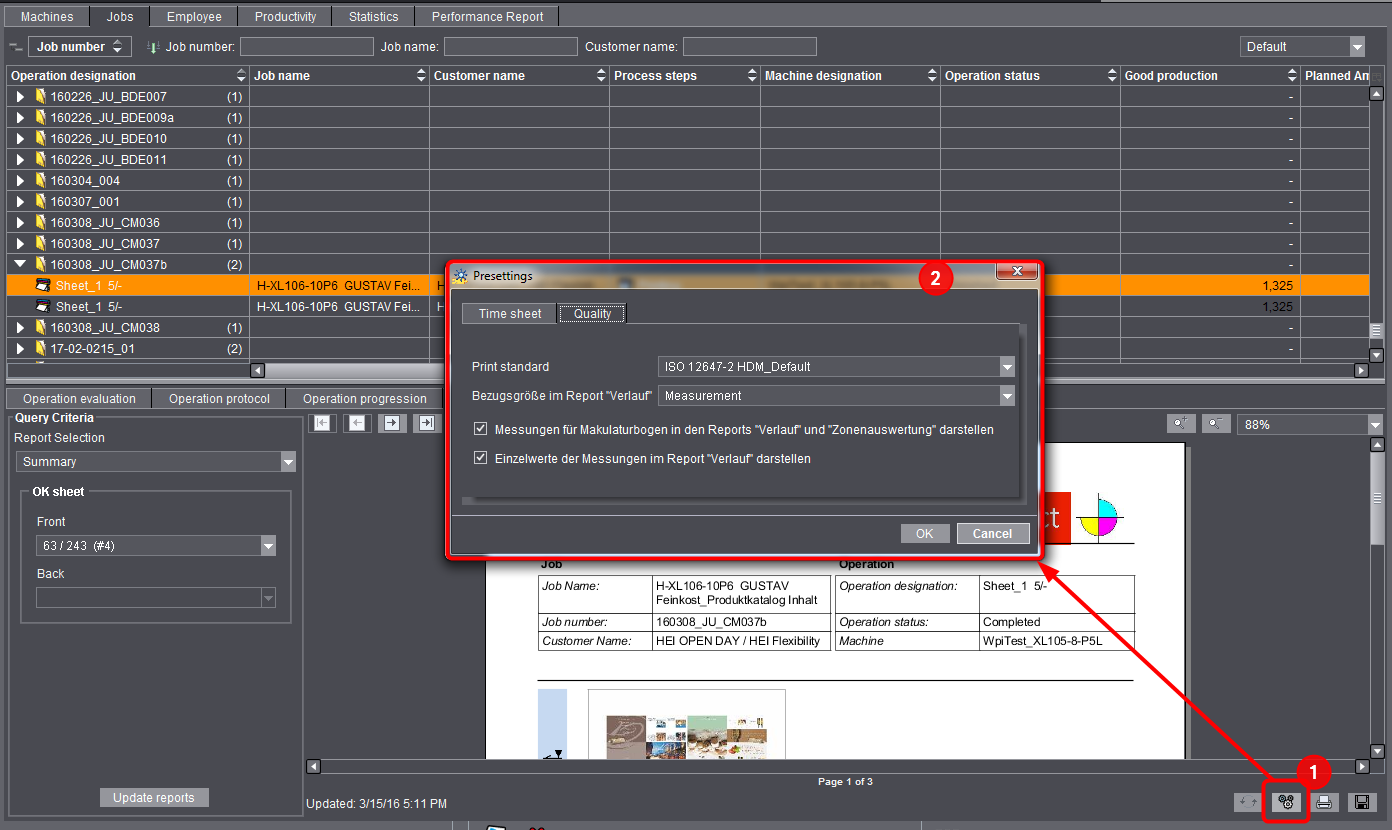

"Job Quality" and the "Summary", "Progress" and "Zone Analysis" operation reports have global presettings that impact the display and analysis.

Proceed as follows to open the Presettings:

1.Go to "Analyze Point > Job Reports".

2.Click the "Presettings" icon (1).

The "Presettings" dialog displays (2).

This is where you define the global presettings for the quality reports.

"Print standard"

Based on the set standard, in the "Job Quality" and "Summary" quality reports the quality of the OK sheet is checked against the value of the wet ink set. By default, the "ISO 12647-2 HDM_Default" print standard is set.

"Reference Value in the "Progress" Report"

The selected reference value displays on the x axis in the "Progress" report. See "Progress" Report.

""Show measurements for waste sheets in the "Progress" and "Zone analysis" reports""

When this option is enabled, measurements in good production and measurements during makeready are assessed in the "Progress" and "Zone analysis" reports.

"Show single values of measurements in the "Progress" report"

The values measured for Delta E, density and dot gain display on the last pages of the "Progress" report when this option is enabled.

3.Save your settings with "OK".

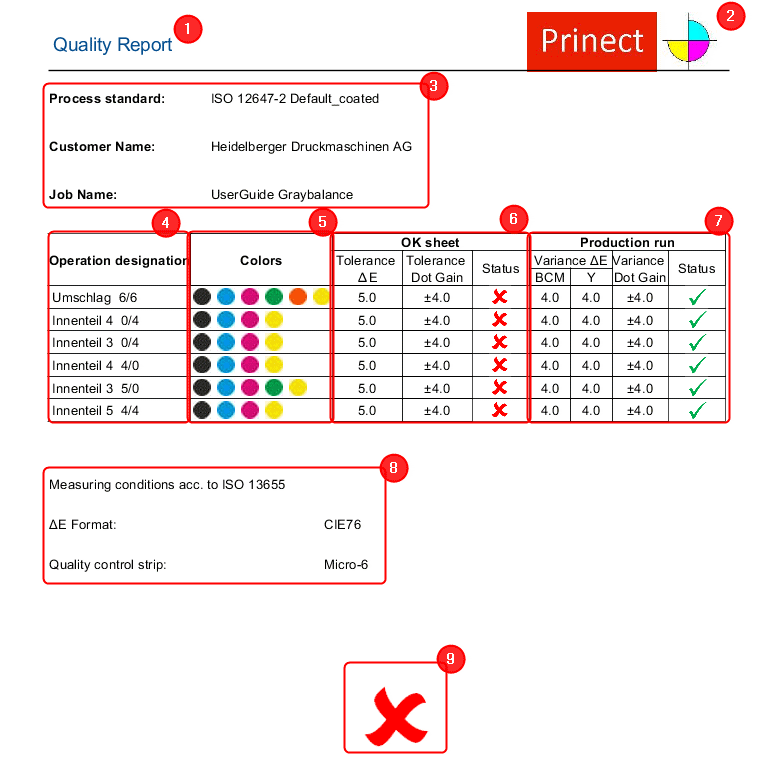

"Job Quality" report

Report title (1)

The logo you selected (2). See Logo.

Header data (3):

•Print standard you selected. See Presettings - quality reports.

•Customer Name

•Job Name

List of operations:

•Operation designation (4):

lists all print operations

In case of separate front and back printing, two individual operations will be listed. "No data found!" appears in the "OK sheet" and "Production run" columns if there is no data.

•Colors (5):

Operation colors

•OK sheet (6):

Note: Choose the OK sheet in the operation report "Summary". See OK sheet.

·Tolerance ΔE:

Delta E tolerance permitted for the OK sheet according to the print standard.

·Tolerance Dot Gain:

Dot gain tolerance permitted for the OK sheet according to the print standard.

·Status:

Evaluation of the OK sheet with the Status icon indicating whether or not the sheet complies with the tolerances. See Status icons.

•Production run (7):

·Variance ΔE (BCM):

Delta E variance for Black, Cyan and Magenta the print standard allows for good production.

·Variance ΔE (Y):

Delta E Yellow variance permitted for the OK sheet according to the print standard.

·Status:

Evaluation of the production run with the Status icon indicating whether or not at least 68% of the good sheets are within the specified variance. See Status icons.

Note: The specified tolerance and variance values are not the real measured values but the deviations permitted by the print standard.

Further information (8):

•Measuring conditions:

Used print standard

•Used ΔE format. The "CIE76" standard is used currently.

•Quality control strip:

lists all control strips used for color measurement during all print operations

Overall evaluation (9):

|

Status icon |

Explanation |

|---|---|

|

OK sheet The quality of the operation is OK. The OK sheet does not exceed the tolerances specified in the preset print standard. Production run The quality of the production run is OK. At least 68% of the operation's good production is within the tolerance as compared to the OK sheet. Total results The quality of the job is OK. All operations of the job - the OK sheet result and also the production run result - are OK. |

|

OK sheet The quality of the operation is not OK. The OK sheet exceeds the tolerances specified in the preset print standard. Production run The quality of the production run is not OK. Less than 68% of the operation's good production is within the tolerance as compared to the OK sheet. Total results The quality of the job is not OK. At least one OK sheet or production run result of an operation is not OK. |

|

Total results At least one operation of the job has no suitable data, or at least one operation has not yet been printed. |