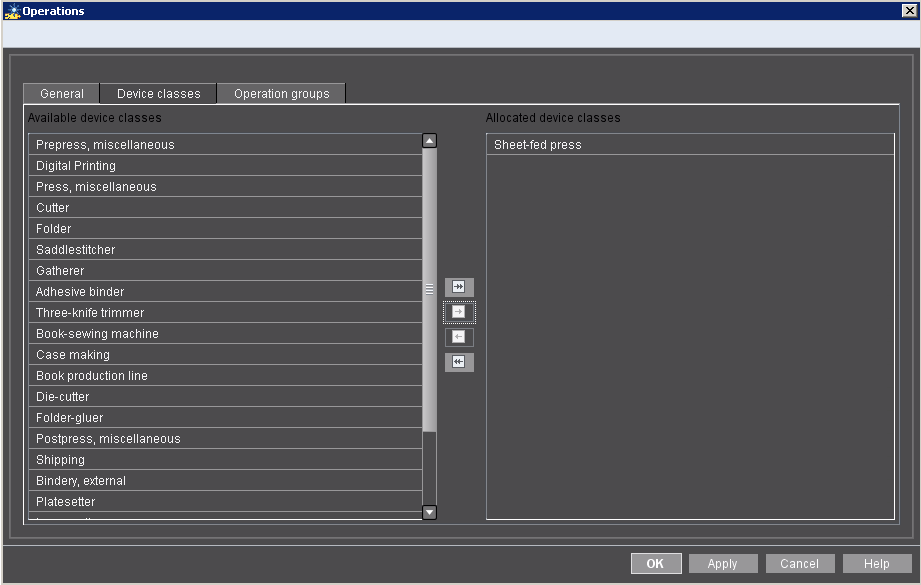

This tab is used to define the device class (printing press, cutter, etc.) to which this operation (PDC message) is to be automatically assigned. If, for example, you want this operation to be automatically assigned when defining printing presses, you have to assign the "Sheetfed press" entry to the "Allocated device classes" section here.

If you do not assign anything, this operation is assigned to each new device created.

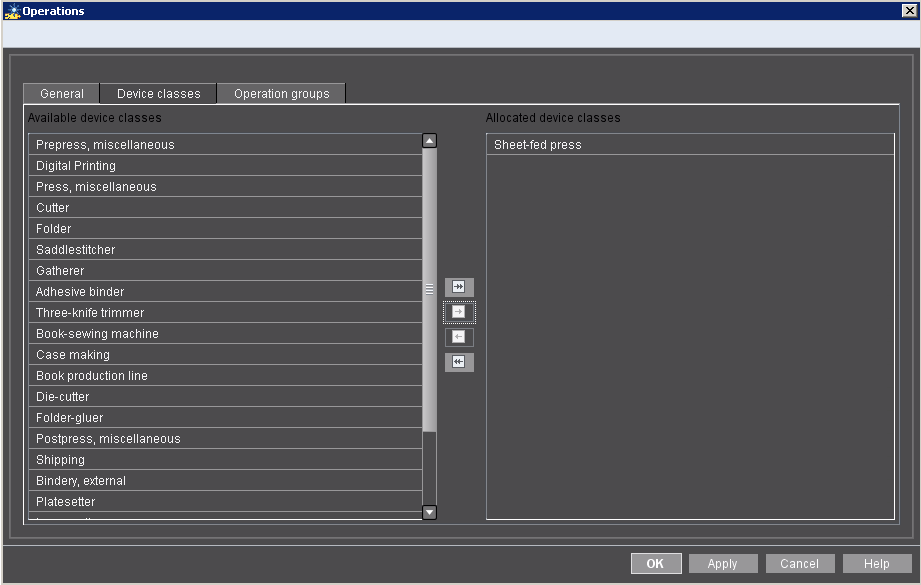

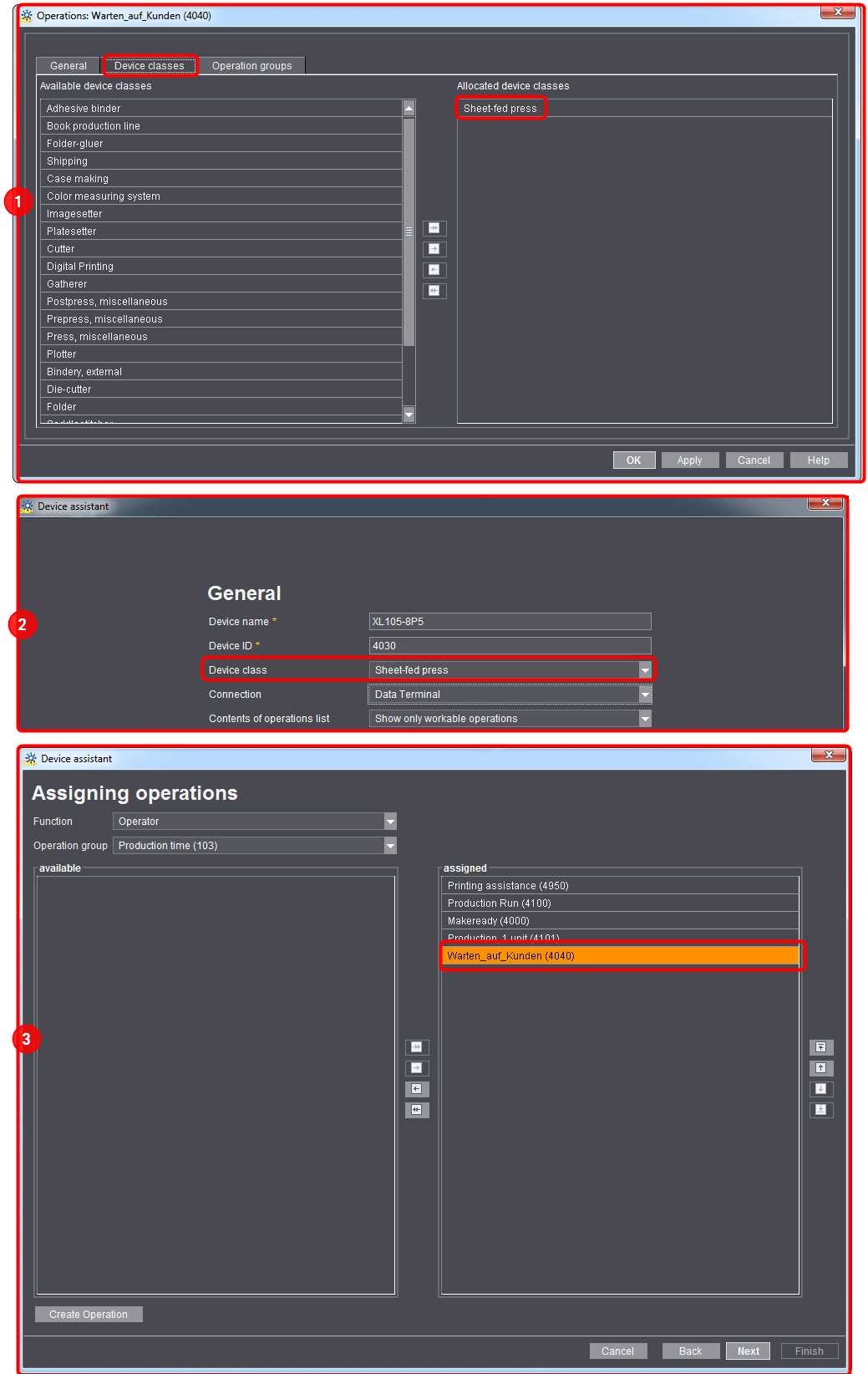

When creating a new device, this operation is automatically assigned to the device through the operation group. The following figure illustrates this.

In principle, the modules required in practice have already been created for all machines that are connected via the Central Device Manager (CDM). Therefore, you need to define new modules only in special cases.

The modules that you define here are then available as "available modules" for defining variants when creating the devices.

•What is such a module needed for?

What is such a module needed for?

A job generally consists of several operations. In order that an operation can be processed by a machine, at least one module is required in all cases. For example, the "Printing unit" module is required for a printing press. So that it can also process jobs involving print enhancement (varnish), this press also requires the "Coating unit" module. If you combine both modules, you obtain a variant.

In the case of the saddlestitcher, for example:

•Variant_1 consists only of the "Gathering" module.

•Variant_2 consists of the "Stitching" module and the "Three-knife trimmer" module.

•Variant_3 consists of the modules "Gathering", "Stitching" and "Three-knife trimmer".

Different variants are required in finishing, in particular depending on the type of job to be processed.

You can find a detailed description of the variants in Setting up variants.