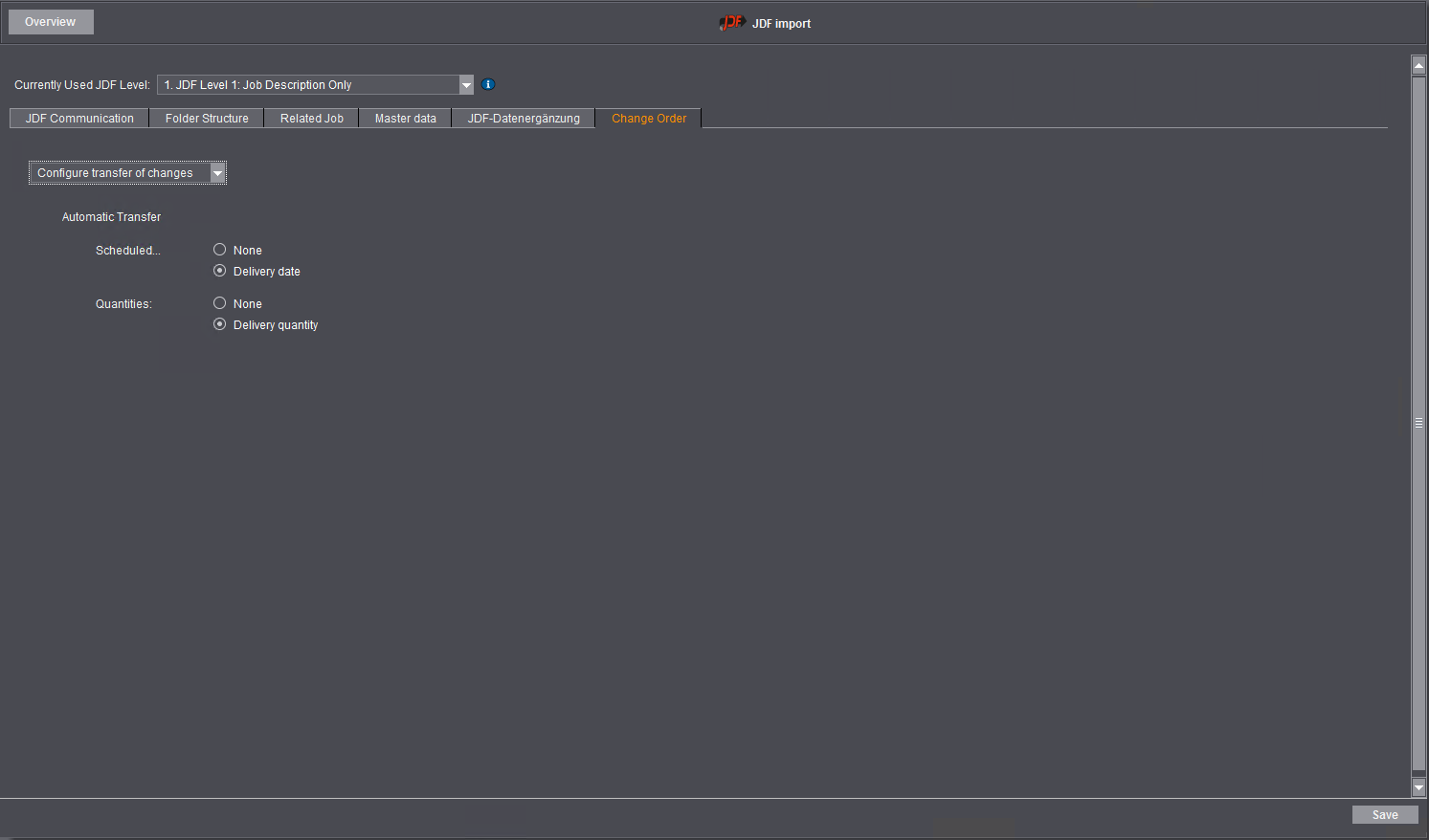

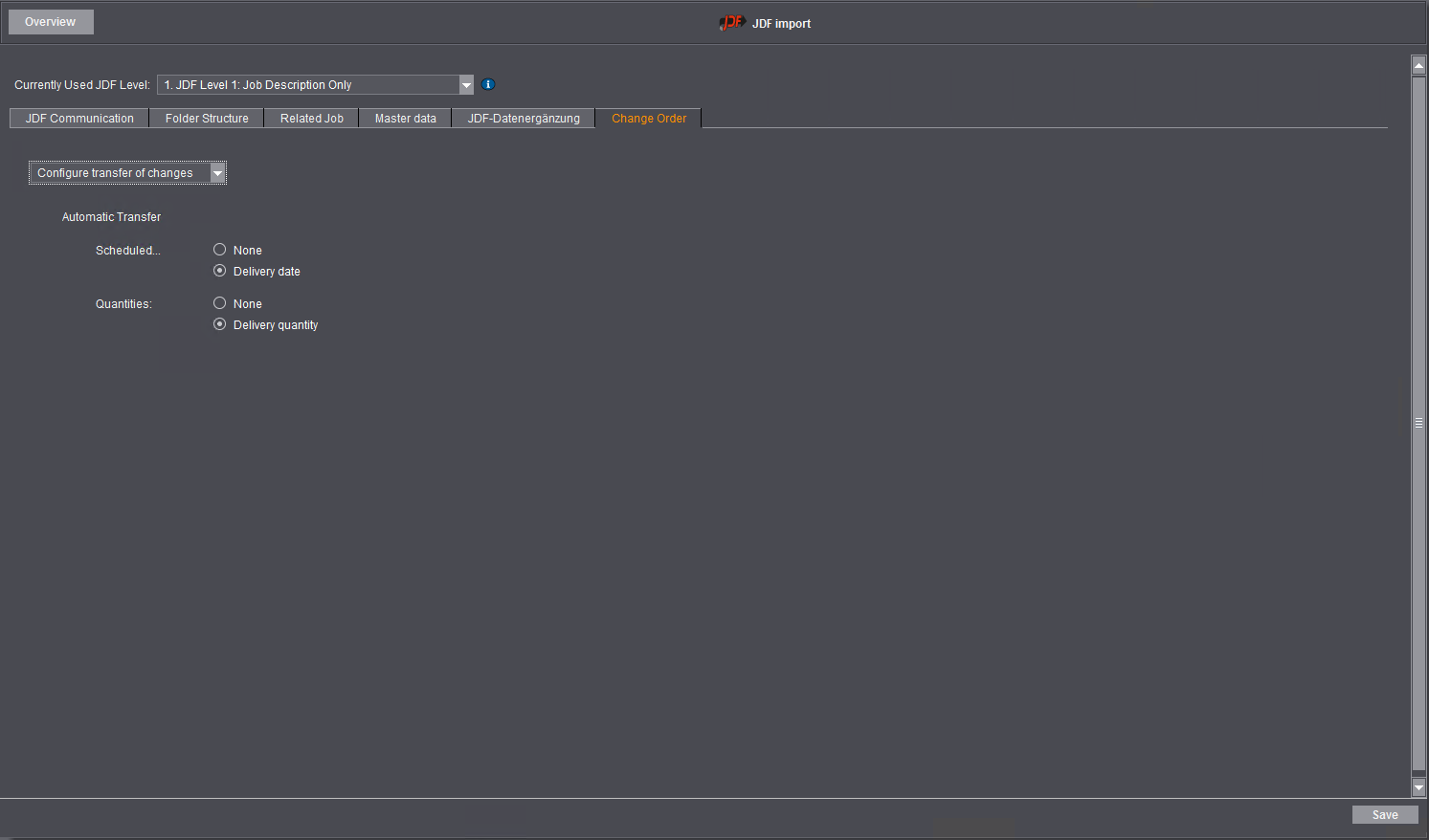

In this tab you configure how job changes made in the MIS are applied in Prinect Manager during import.

The Prinect Manager automatically detects any changes in an existing order made by a Management Information System (MIS). The job data already entered is compared against the new job data here.

In "Change Order", you can configure for many possible order changes whether a "Change Order" request is adopted/accepted or rejected by the Management Information System (MIS) and define the boundary conditions. You can find a detailed description of order changes in the section Change Orders with MIS.

You can choose from the following options in the list box in the upper tab area:

•Do not apply any changes

Job changes from MID will not be applied if you enable this option. Accordingly, no further options are visible.

•Configure transfer of changes

All other options are visible and operable.

•Use all changes

All job changes are applied without further configuration.

Automatic transfer

Scheduled times

The scheduled times change, for example, if there are changes to quantities and colors and if there is a change in the page total.

The scheduled times from the Scheduler are overwritten if you use scheduled times from the MIS. If applicable, you must make the change manually in the Scheduler if you do not wish to apply the scheduled times from the MIS.

The following options are available:

•None

No scheduled times are applied.

•Delivery date

Only the delivery date is applied from the MIS.

•Detailed Scheduling

The entire detailed scheduling is applied from the MIS.

Quantities

Quantity changes are related to scheduled times. If you accept quantities but not scheduled times, there are discrepancies in the Scheduler because the scheduled times are not recalculated there.

The following options are available:

•None

No quantities are applied.

•Delivery quantity

Only the delivery quantity is applied from the MIS.

•Process Quantities

All the quantities defined in the MIS processes are applied.

"Paper Availability" option

Paper availability displays whether paper is ordered, supplied or available. This data about the material generally comes from the MIS and can be transferred for planning to the Prinect Manager.

You can set the following parameters for these options:

Transfer

You can choose between the following options:

•None

No data is applied.

•Manual

If relevant changes were made before printing, for example, a note about job changes displays in the job list and in the open job. The user must accept the change before it is applied. You will find details about how to accept a change in Accept/reject order changes manually.

•Automatic

The MIS values are automatically applied.

If relevant changes were made before the plates were imaged, for example, the changes are applied automatically and the user does not have to accept them first. However, to keep the user informed about the change, a warning about job changes displays in the job list and in the open job. This warning disappears only when the message was marked as "Read". You will find details about how to mark a change as read in Mark a Change Order as "read".

until start of

You can choose between the following options:

•Plate imaging

The transfer criterion selected beforehand refers to the start of plate imaging.

•Printing

The transfer criterion selected beforehand refers to the start of printing.

Paper

Depending on the configuration of Change Order, changes to paper works only semi-automatically. This means that paper changes are active only when you open the layout in Prinect Signa Station after the change and output it to the Prinect Manager.

Layout and Page Count

The following MIS changes in layout and page count trigger job changes in the Prinect Manager:

•Change sheet list (add, rename or remove sheets)

•Change page size

•Change folding type

•Change language

•Change number of pages

Layout changes are closely related to other changes. For example, deletion of a sheet brings about a change in the layout and a change in processing.

For that reason, each of the change items must match each other when configured.

Caution: Manual changes to a layout can be lost when you accept layout changes from the MIS.

To prevent this, we recommend that you make changes to the layout manually and do not accept the layout changes.

Colors

Changes to colors from the MIS works only semi-automatically. In other words: the Cockpit operator must change the colors manually in the Cockpit when a change has been applied.

Processing

The following changes affect processing: adding, renaming and removing sequences and operations.

Processing is closely related to the layout. For that reason, we recommend that you coordinate configuration of the layout change and the processing change.

Machine

Changes to the machine work only semi-automatically. This means that the Cockpit user must still edit the machine sequences (SheetfedPrinting, PagePrint, ImposedPrint) manually in the Cockpit after the changes are accepted.