Binding, Gluing folding cartons

The operations shown are sorted by sheets (in binding, sorted by product or product part). Within a sheet, the operations shown are sorted by their order in the production run. Each product part/version is listed at least once even if no operation is assigned to it (operation crossed out).

You can add and delete operations.

Functions in the "Binding" planning step

|

Context Menu/Button/Option |

Description |

|---|---|

|

New Operation Before |

The inserted operation is processed before the currently selected operation during the production run. See "New Operation Before" / "New Operation After". |

|

New Operation After |

The inserted operation is processed after the currently selected operation during the production run. See "New Operation Before" / "New Operation After". |

|

Split Amounts |

The selected operation is split into two equal operations. As a result, the total amount can be split and produced in parallel on several machines. Note: Be sure to make several plate sets if you want to print on several machines at the same time. |

|

Merge Amounts |

Select several operations whose amounts you split in an earlier step and combine them together again with this button. |

|

Add Stock Quantity |

This function lets you create a new operation for adding a production volume to stock. As a result, you can use available capacities, for example, and produce in advance for a later repeat job. See "Add Stock Quantity" and "Remove Quantity from Stock". Remember there is no automatic feedback to stock management. |

|

Remove Quantities from Stock |

This function lets you create a new operation for a stock withdrawal. This gives you the option of removing a quantity for a product part from a predecessor job (e.g. the cover of a booklet). |

|

Production |

•delegate •execute |

|

Delete |

The selected operation is deleted irrevocably. |

|

Binding |

Editing a versioned operation results in all other versions of the operation having the same binding mode. |

"Machine" / "Variant" list boxes

Select the machine you want and the variant of this machine you want. If allowance, setup time and production time are set up for the selected machine, then these data are set by default in the input boxes. (You can view the setup of the machine in the Device Assistant in "Administration > System > [name of Prinect server] > CDM > selected machine > Edit" in context menu.) The "SheetFinishing" and "StitchFinishing" sequences are set up automatically based on the selected machines and variants.

"New Operation Before" / "New Operation After"

Sometimes it is necessary to manually set up the process network for binding operations or match the existing process network. What's more, these process networks can be very complex and binding operations have to be based on the results of preceding binding operations (for example, if a compiled and sewn book block is glued with front/back end sheets).

Using "New Operation Before" and "New Operation After" it is possible to set up such a process network manually.

1.To do this, delete all suggested operations.

2.Extend the process network starting with the last operation (e.g. tumbling the protective cover) by selecting the machine and the variant.

3.Create the preceding operation (e.g. inserting book block and cover) using "New Operation Before".

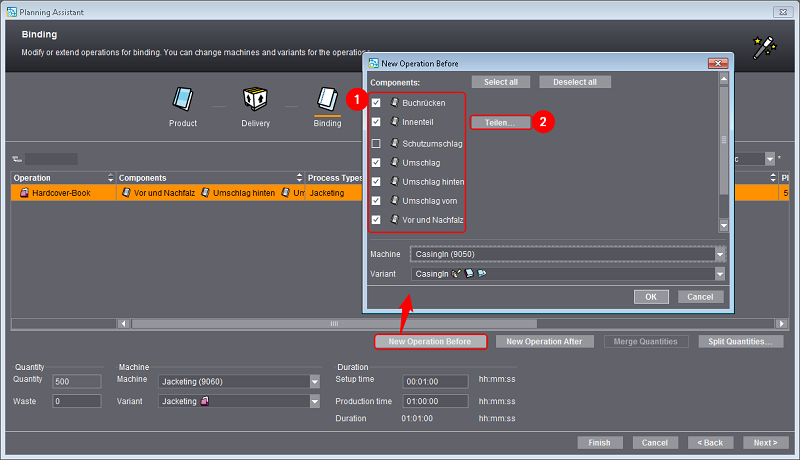

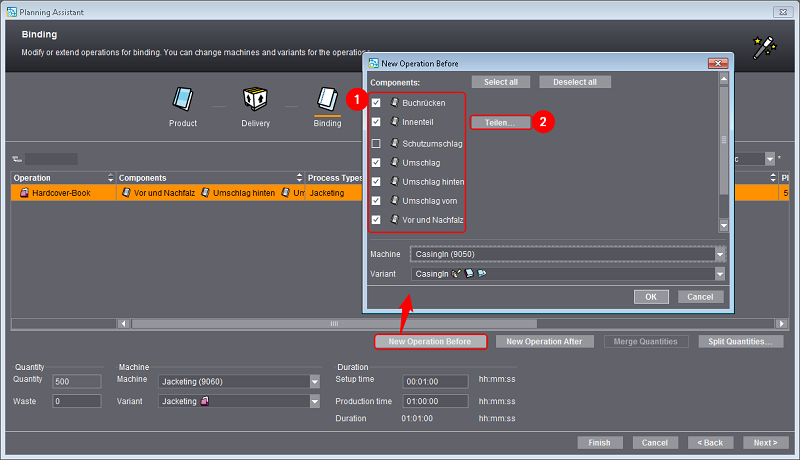

4.In the "New Operation Before" dialog, select the components to be processed during the operation (1). You can split several sheets across several operations with "Split" (2).

•Note on splitting

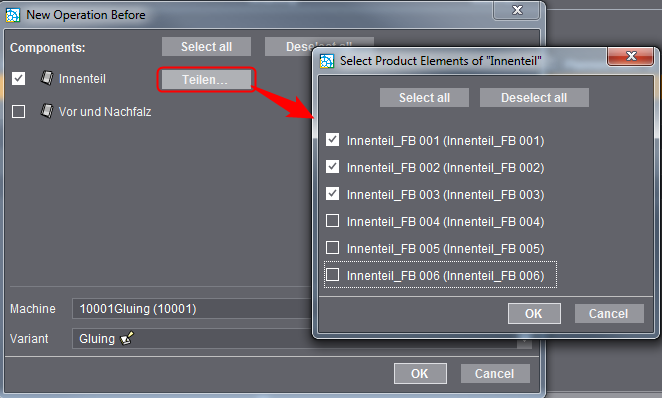

Sometimes it is possible to only process some sheets of a large product part (e.g. during preliminary ganging). When creating a new binding operation, you can also select a subset instead of the whole product part.

To do this, select "Split" and enable the sheets that are to be processed in the operation concerned. After that, confirm with "OK".

5.Using "New Operation Before", create all other operations until you have completed the process network.