Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes

Some prepress systems do not allow the objects in the job (pages, images) to be rotated or mirrored and then saved to the PPF file. The objects are written to the PPF file in the way they are output on the imagesetter. To allow useful area coverage values to be calculated, the objects must have the correct orientation.

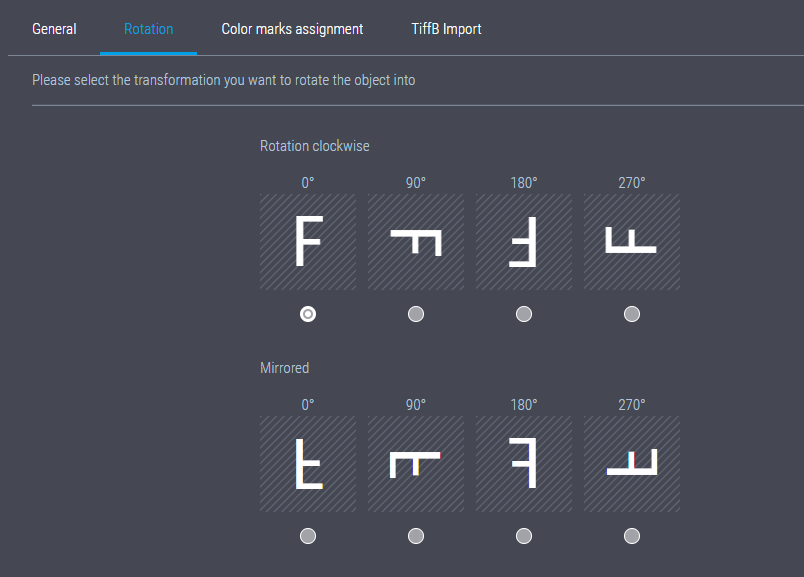

"Clockwise Rotation" group

Here you can select the rotation angle of objects in clockwise direction.

"Mirrored" group

Here you can select how the objects in the PPF are to be mirrored.

Rotation and/or mirroring is shown in the sheet preview.

Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes