Using rules, you can use different automarks within a job, depending on the press sheet (for example, different settings for certain customers).

In this way, you can for example insert a number of different press sheet labels and control placement specifically for each customer.

As a general rule:

•You can insert each rule type only once per selected automark.

•If there are several rules for an automark, this configuration is used if all the rules are applicable (And operation).

•In the case of several criteria within a rule, this rule is applicable if one of the criteria is met (Or operation).

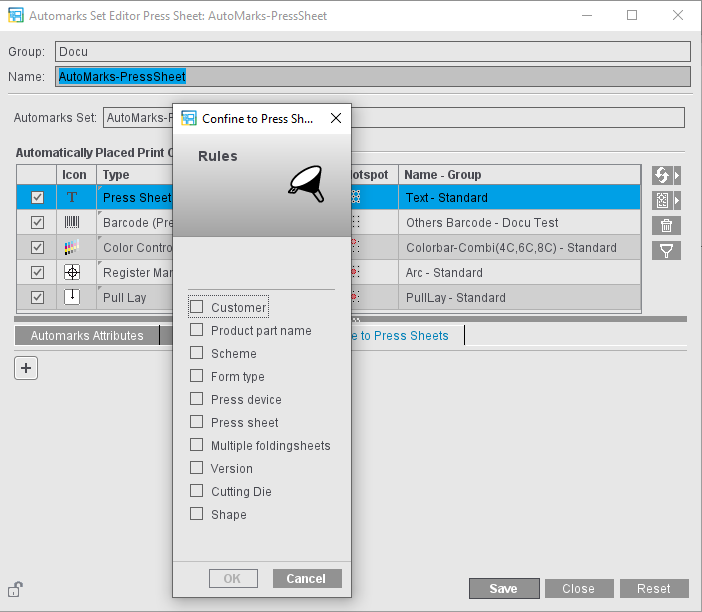

1.By clicking the Plus button, you open the rules dialog to add a new rule.

2.Select the rule you want and click "OK" in the dialog.

3.Define the restrictions that you want:

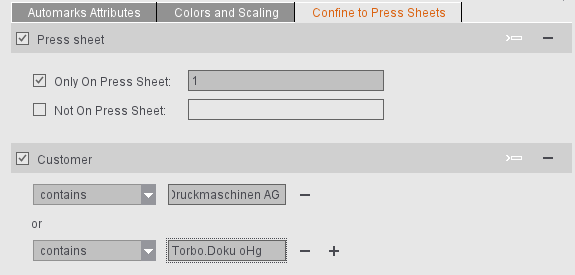

•Customer: Enter the customer name. All suitable items display for selection in a list. Typing errors can be avoided in this way. Then you select whether the currently selected mark is to be placed for this customer or not. You can use the plus sign to the right of the name box to add other customers for whom this mark will be placed.

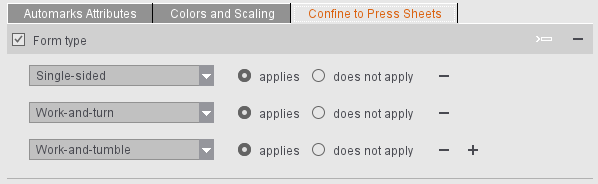

•Work Style: By selecting a work style from the list, you can define on which surfaces the automark is to be placed or not. For example, you can define that the mark will be placed only on single-sided surfaces.

•Multiple Folding Sheets: The "Multiple Folding Sheets" rule makes it possible for a press sheet automark to be placed only when all folding sheets on the press sheet, regardless of the scheme used, have an identical page list. This is needed, for example, in the Push2Stop workflow. The rule name is related to the term "Multiple 1ups".

When the rule is selected, the page lists for all folding sheets on the press sheet must have the same indices (the number of pages per folding sheet is identical and the pages each have the same index, irrespective of the position in the scheme). The schemes used are irrelevant in this case. The automark is not placed if different folding sheets with different page lists are on the press sheet.

•Press/Product Part Name: You can confine placement of the mark to certain presses or product parts by entering the name of a press or product part. You can use an exact name or part of the name depending on the selection in the list. The list displays all items defined in the system that match the input part.

•Press Sheets: You can confine placement of the automark to certain press sheets or exclude certain press sheets. When entering the press sheets, you can also specify several press sheets (separated by a semicolon, e.g. "1;3") or a range of press sheets (e.g. "5-8").

•Version: In versioned jobs, it can be a good idea to place certain marks depending on the version that is on a press sheet. In this way, for example, additional or different text marks to the press can make it easier to recognize the various versions. The "equals" settings lets marks be placed on homogeneous press sheets: the automark is placed only on press sheets that have this version only. The "contains" setting makes sure that the automark is placed on all press sheets that have this version at least once. "doesn't contain" makes sure that the mark is placed on all press sheets that do not have the specified version.

•Scheme: Marks must be placed relating to the press sheet depending on the used scheme (analogous to automarks sets relating to a folding sheet) for Push2Stop machines and also if the pull lay mark is used.

If the rule is selected, all the schemes on the press sheets must be identical and match the scheme name specified in the rule. The schemes on the press sheet must be homogeneous. The automark is not placed if different schemes are on the press sheet or if the scheme name does not match the scheme name specified in the rule.

•Cutting Die/Shape: Enter the name or part of the name of the cutting die or shape where the mark is to be placed or not placed.

All cutting dies and shapes must be identical (homogeneous) on the press sheet if cutting die and shape rules are evaluated in relation to a press sheet. All cutting die shapes must be identical if the shape rule is evaluated in relation to a cutting die (if a cutting die label is used, for example).