Advanced Settings for Sheet Optimization

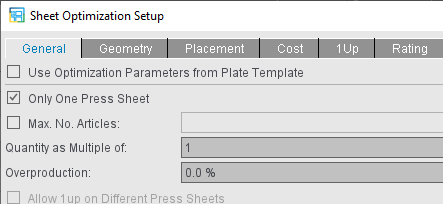

The "Advanced Settings" button lets you invoke all additional settings like the ones also available in the "Sheet Optimization Setup Editor" for creating templates. The "Sheet Optimization Setup" is divided into the "General", "Geometry", "Cost" and "Rating" tabs.

Changes in this dialog are implemented directly. In other words, the values entered are applied immediately without confirmation through the OK button. The dialog must be exited with "OK" if the values are to be kept. The changes are discarded if you exit the dialog with "Cancel" or with the "Close" icon.

Use Optimization Parameters from Plate Template

The optimization parameters from the "Plate Template" and "Papers (Printing Materials)" resources are used and display accordingly when you enable this option. If a number of plate templates or papers are set in your job, proceed as follows:

•Plate templates

The values in each parameter are checked for validity in all plate templates defined in the job and compared with each other. If the values from all the plate templates are valid and identical, the same value displays in the relevant box.

If a value is invalid or different, the word "various" displays in the box instead of a value.

The tooltip of the box also shows all different values of the parameter.

You cannot edit the values.

The value from the job data displays if there are no plate templates.

This will be indicated with a gray square in check boxes that can only be enabled or disabled if multiple plate templates with different settings are loaded in the job:

•Papers

The values in each parameter are checked in all papers to see that they are available. If a value is set each paper, one of these values is used during optimization. To make this clear, the value in the box is blue. However, the value shown is not used for optimization.

If a value is missing in one or more papers, an existing value displays in the standard color in the box and is used if the paper provides the best optimization result.

The tooltip of the box also shows all different values of the parameter.

You can edit the values. Edited parameters are not kept in the paper entered in the plate template but in the job data.

Note: You can set the quality criteria in the "Rating" tab for a specific job even if the optimization parameters from the plate template are used and use them for optimization.

Exactly one good press sheet is generated during optimization. After you save your data, gang parts that are not placed are returned automatically to the pool for gang jobs.

The "Max. No. Articles" box lets you restrict the number of articles on the press sheets to take into account restrictions in finishing (e.g. sorting equipment with a limited number of trays). When you enable the option, the box first displays '10' by default. You can then match this value to suit your needs.

When the number of articles to be placed is greater than the maximum number you defined, the articles are split into partitions, optimization is calculated separately for each partition and finally these single results are added together. For example, for 20 articles and a limitation to five articles, this produces four press sheets each with five articles instead of one press sheet with 20 articles.

Quantity as Multiple of

The quantity is to be a multiple of the number entered in this box. The quantity can be less than this value in the case of an odd number of remaining copies.

Overproduction

You can enter a percentage for overproduction in this box if the calculated overproduction for a job was not specified.

Allow 1up on Different Press Sheets

A check is run to see whether a better result can be obtained by placing the same 1up on different press sheets.

![]() Note: This option is not available if segments are used in sheet optimization.

Note: This option is not available if segments are used in sheet optimization.

Press Sheet Allowance

Allowance for the press sheet quantity, either as a fixed value (base) and/or as a percentage.

For example, waste allowance for finishing.

1up Allowance

Allowance for the 1ups/gang job objects; the delivery quantity is taken as the basis.

Include Separations

Optimization with "Include Separations" gives you only press sheets where the placed documents of a press sheet do not have more colors in total than available printing units. This makes it possible to avoid multiple runs (for details, see Include Separations).

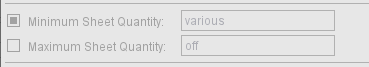

Minimum/Maximum Sheet Quantity

You can control the quantity of sheets resulting from optimization with these parameters. For a digital press, for example, it could be desirable that it will not print sheets whose quantity exceeds a specified amount (= "Maximum Sheet Quantity" enabled and appropriate value entered). An optimization with maximum sheet quantity could then result in the 1ups being distributed on several press sheets whose respective sheet quantities do not exceed the maximum sheet quantity.

With the maximum print quantity, it is also possible to force that very high quantities of 1ups are always printed as multiple ups. The set maximum sheet quantity will not be exceeded even in this case: If it is impossible to place all required 1ups on the maximum number of sheets, optimization will abort with an appropriate error message.

In turn, a minimum quantity could be feasible for an offset press.

Note: You can also set the defaults for the sheet quantity in the plate template. With the option "Use Optimization Parameters from Plate Template" enabled, the fields in the job are disabled and the values from the plate template are displayed. If the job contains several plate templates with various settings, the fields display "various".

Slider for less plates / less sheets

The slider lets you weight the priority, in other words whether less plates or less press sheets will be used. The digits only portray the weighting for the algorithm and are not important otherwise.

Note: The slider does not necessarily improve optimization in every job. In some cases, the result is identical.

Note: The geometry data are not read from the MDS but you must define them yourself in this tab.

Left Margin / Right Margin / Top Margin / Bottom Margin

By defining these margins, you create a bounding box within which the 1ups can be positioned. If you leave the default values of "0" as they are, the bounding box is the same size as the paper. By entering values for the margins, you shrink the size of the bounding box accordingly.

If you set marks at the left, right and top, you must set a margin for these marks.

Margin around 1up block

Spacing between the folding sheets/assembly blocks. You must set the value to "0" for a separating cut.

With the option "Only for marginless 1up", you can ensure that the set "Margin around 1up block" is not added to the already existing margin for 1up with margin, but is only used for 1up without margin. 1ups are considered "marginless" if at least one margin=0.

In optimization, you can reserve spaces on the sheet for any sheet brakes that may be required. You can set up to 12 sheet brakes.

The standard width of a sheet brake is 7 mm. In addition to this value, one or two standard trims are kept free so that no trim juts into the sheet brake.

In case of 2 or more sheet brakes, one brake each is expected on the left and right margin respectively; should the space be insufficient, it will be expanded internally

For single surfaces, sheet brakes do not require any lanes and therefore will not be considered by Signa Station. For this reason, you could also use parameter sets with sheet brakes for single surfaces

There is no horizontal centering for (effective) sheet brakes because otherwise the positions of the lanes would be unpredictable.

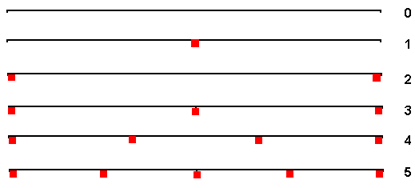

Schematic view of assumed positions for 0-5 sheet brakes:

Note: For "Single-sided work-and-turn", the meanings of left and right margin apply analogously to the sheet halves. This may also result in increased margins because of the sheet brakes to consider. A peculiar situation arises with even sheet counts of 4 and more since a smaller strip is formed on the sheet half.

Horizontal lanes/width/height

In addition to the number of sheet brakes, you can also set their width and the number and width of the horizontal empty areas (lanes).

The sheet brakes and the horizontal lanes must always cover the entire height and/or entire width of the press sheet. That is why the number is interdependent. An appropriate lock is integrated into the graphic user interface and described as a tooltip.

If one or more than 2 sheet brakes are selected, these are centered on the press sheet. In this case, only the values of '0' or '2' can be selected for the horizontal lanes. Accordingly, it is vice versa if the number of horizontal lanes is first entered.

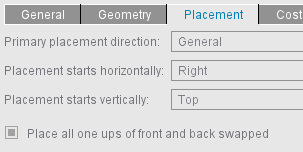

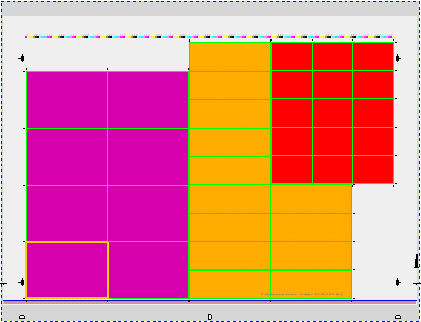

For "Sheet Optimization without Layout Default", you can also define the placement, that is, the starting point as of which the gang parts are aligned on the press sheet.

With the first cut opposite the lay edge, normally as many elements as possible are to be cut. This variable setting option makes sure that you can match optimization to suit your needs.

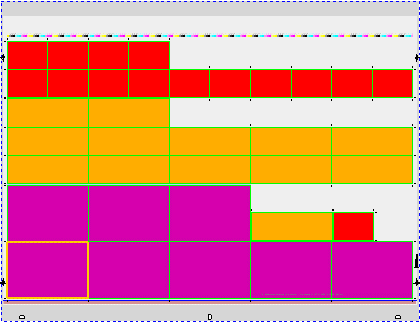

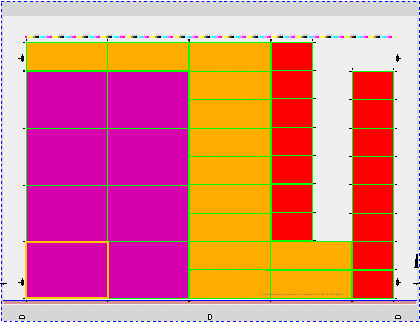

During optimization, the assembly blocks are grouped by size. Assembly blocks of the same size placed side by side make up what is known as a "ribbon". If possible, the bigger assembly blocks are always positioned more to the left. Positioning normally begins at the bottom left. If needed, you can change the starting point for optimization in horizontal and vertical direction.

Primary placement direction

"Horizontal": Sheet optimization is in horizontal ribbons. They always fill the entire space between the margins before a new ribbon begins.

"Vertical": Sheet optimization is in vertical ribbons. They always fill the entire space between the margins before a new ribbon begins.

"General": Sheet optimization is in rectangles (or rectangular ribbons). In other words, assembly blocks of the same size are grouped together to form rectangles if possible. In most cases, the rectangular ribbons don't fill the entire space between the margins.

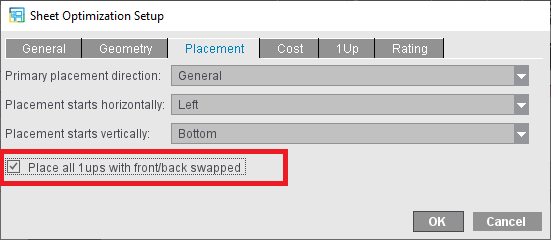

Option "Place all 1ups with front/back swapped"

This will swap all 1ups of the gang job from the front to the back and from the back to the front. This may be desired, for example, on presses with a perfecting device so that the print results are delivered face up and the stacks do not have to be turned in an additional operation for this purpose.

As a rule, swapping is applied to all 1ups of the ganging job. If jobs where swapping has already been done are added to the ganging jobs, their fronts and backs will be swapped again.

The option can also be set in the plate templates. If you enable the "Use Optimization Parameters from Plate Template" option in "General", the placement settings in the job will be disabled, and the plate template settings are displayed.

The checkbox has a gray square if multiple plate templates with different settings are loaded in the ganging job.

Note: If you also work with the "Include Separations" option, the ganging job may not be processed if the colors set for the front and back no longer match the settings for the separations after swapping.

Is equivalent to the cost data for sheet optimization (see Cost Data for Sheet Optimization) with an additional input option for the press for hourly rate and performance (sheets per hour).

Note: The cost data are not read from the MDS but you must define them yourself in this tab.

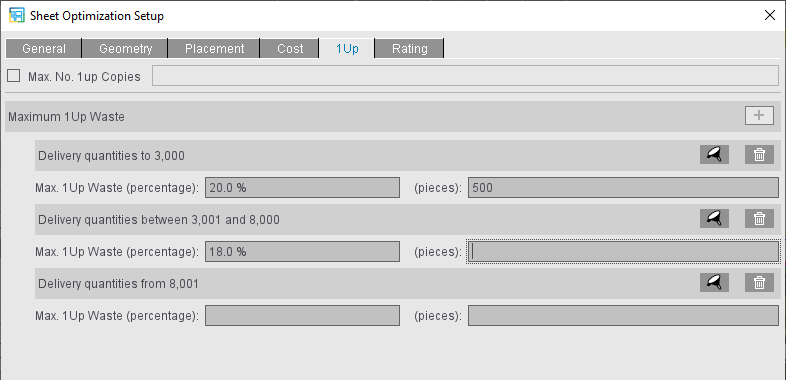

"1up" Tab

Max. No. 1up Copies

This lets you confine the maximum number of 1up copies on a press sheet to the specified value (by default, the option is disabled).

Rating criterion "Maximum 1up waste"

If a job contains very different delivery quantities, the job parts with low delivery quantities can result in a high amount of waste. The "Maximum 1up waste" rating criterion can be used to set the maximum amount of waste per 1up that may be generated, depending on the delivery quantity.

1.Click the plus symbol to add another rating criterion.

2.To begin with, specify the delivery quantity for which the 1up waste is to apply to.

This allows you to control the maximum 1up waste, depending on the delivery quantity. For example, a lower absolute value could be desired for a low delivery quantity and a lower percentage value for a large delivery quantity. If the criterion is to apply regardless of the delivery quantity, leave the default setting 1 to infinity in the "Edit Delivery Quantities" dialog.

3.Enter values for the maximum waste as a percentage of the delivered quantity and/or the maximum absolute value. Optimization then uses the one of the two values that generates the lower waste in relation to the desired delivery quantity.

For example, values entered for "pieces = 500" and "percentage = 20"

For a desired delivery quantity of 500 pieces, the percentage, i.e. the maximum waste produced, may be 100 pieces.

For a desired delivery quantity of 3000 pieces, the absolute value applies to 500 pieces, since the percentage would be higher with 600 pieces.

For a delivery quantity of more than 3000 pieces but a maximum of 8000, the percentage value of 18% is always used because no value has been entered in "Pieces".

If the delivery quantity exceeds 8000 units, the maximum 1up waste is not taken into account because no values are entered in both fields.

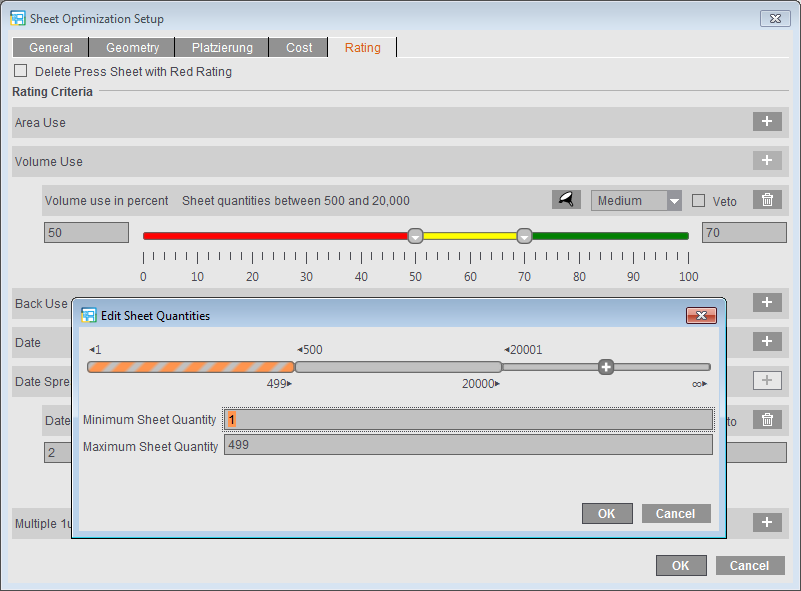

You can define one or more rating criteria for the press sheets depending on your individual requirements by clicking the plus button. The results of these quality criteria display in the "Results" step in the table in "Optimization Result" and in the HTML report.

|

Area Use |

Utilization of the area on a press sheet "Area Use" is set by default when you first open the settings and for jobs from predecessor versions. |

|

|

Volume Use |

Volume Use refers to the press sheet stack |

Can be filtered by sheet quantity: the criterion is applied only to sheet quantities within the set range. See Edit Sheet Quantities/Delivery Quantities for details |

|

Back Use |

Percentage of the back in relation to the front, in other words to the area utilized |

You can set whether a sheet with an empty back is rated to 0% or 100% using the button with the three dots. This can be feasible for ganging of the "Front Only" type, i.e. for creating surfaces with an empty back. |

|

Date |

Assessment of the press sheets based on a uniform target date. "Oldest Target Date" refers to the date furthest back in the past or to the next date in the future. |

You can define a period (Oldest Target Date + x days) using the button with the three dots. |

|

Multiple 1ups |

The rating for multiple 1ups is 100% if each article is placed just once only. |

Can be filtered by delivery quantity: the criterion is applied only to placed 1ups with a delivery quantity within the set range. For example, you might not want multiple 1ups for small delivery quantities but would like to allow multiple 1ups for large delivery quantities on the same press sheet. See Edit Sheet Quantities/Delivery Quantities for details |

Note: With a sheet optimization setup generated with Signa Station version 2020, "Date Spreading" (number of days that may lie between the single jobs at the most) may also be available as a criterion. This was replaced by "Date" in version 2020.10.

In the "Rating" tab, you can set thresholds for a "yellow" traffic light state and a "red" traffic light state.

The slider has two handles, only one of which can be active at a time. The active handle is highlighted by a colored border. A handle becomes active by moving it, by a click on it or a click in the relevant text box.

In addition to moving the active handle, you can change its position by clicking somewhere on the slider.

Use the left handle to change the threshold for the red state and the right handle to change the threshold for the yellow state.

The positions of the slider and the values in the text boxes correspond to each other.

Rating results

Note: For Sheet Optimization without Layout Default, the percentage for the rating result refers to the whole press sheet. For Sheet Optimization with Layout Default and Sheet Optimization for Packaging, the percentage refers to the default layout or cutting die. In other words, a completely filled layout produces, for example, an area utilization of 100% even if the whole press sheet was not used. This rating, varying according to optimization type, is applicable for all quality criteria except for date spreading.

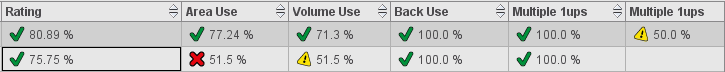

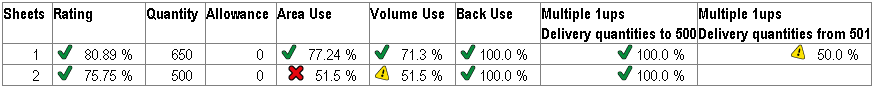

The traffic light position and the values display in the press sheet lists of the HTML report and in the "Results" step. The "Rating" in the report is equivalent to the overall rating that is calculated from all defined rating criteria according to the degree of their weighting.

The results for each single quality criterion defined also display in the press sheet list and in the report. The "Multiple 1ups" column can display several times if the criterion is defined for different delivery quantities. The "Volume Use" criterion can also be defined several times (for different sheet quantities), but it always only displays once (volume use matching the optimized sheet).

Display in the "Results" step in the press sheet list:

Note: To view the criteria in the report, you must add the criteria to the table of the press sheet list with "Select Columns". In this case, only the columns where criteria are also enabled display.

Display in the HTML report:

Delete Press Sheet with Red Rating

If "Delete Press Sheet with Red Rating" is enabled, press sheets that are below the left threshold, i.e. in the red, are removed automatically from the gang job.

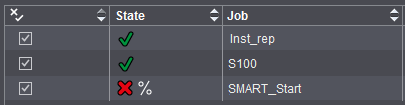

During optimization, a warning message is issued and the removed jobs are highlighted accordingly in the "Results" step in the "State" column in the 1up list: