•Explanation of the Time Evaluation

•Explanation of Time Categories and Time Types

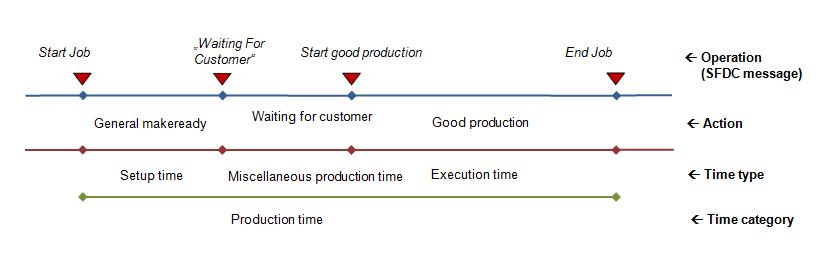

•Interdependency between Operation, Action, Time Type and Time Category

Time evaluation...

•...is used to evaluate the processes in your company.

•...provides a gapless visualization of times accrued at the machine.

•...allocates accrued times to production time, auxiliary time and downtime.

•...lets you easily track machine standstills.

Explanation of the Time Evaluation

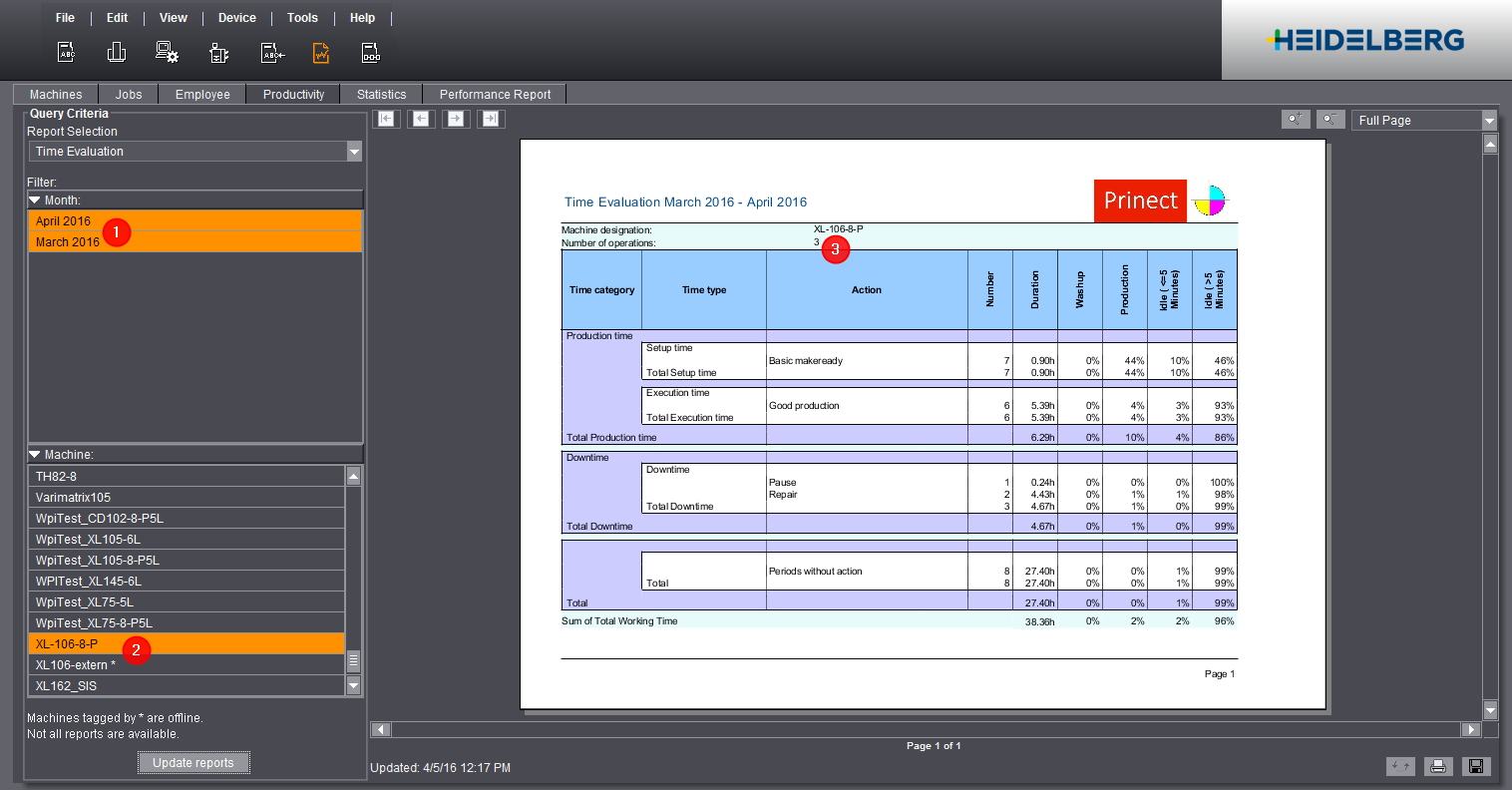

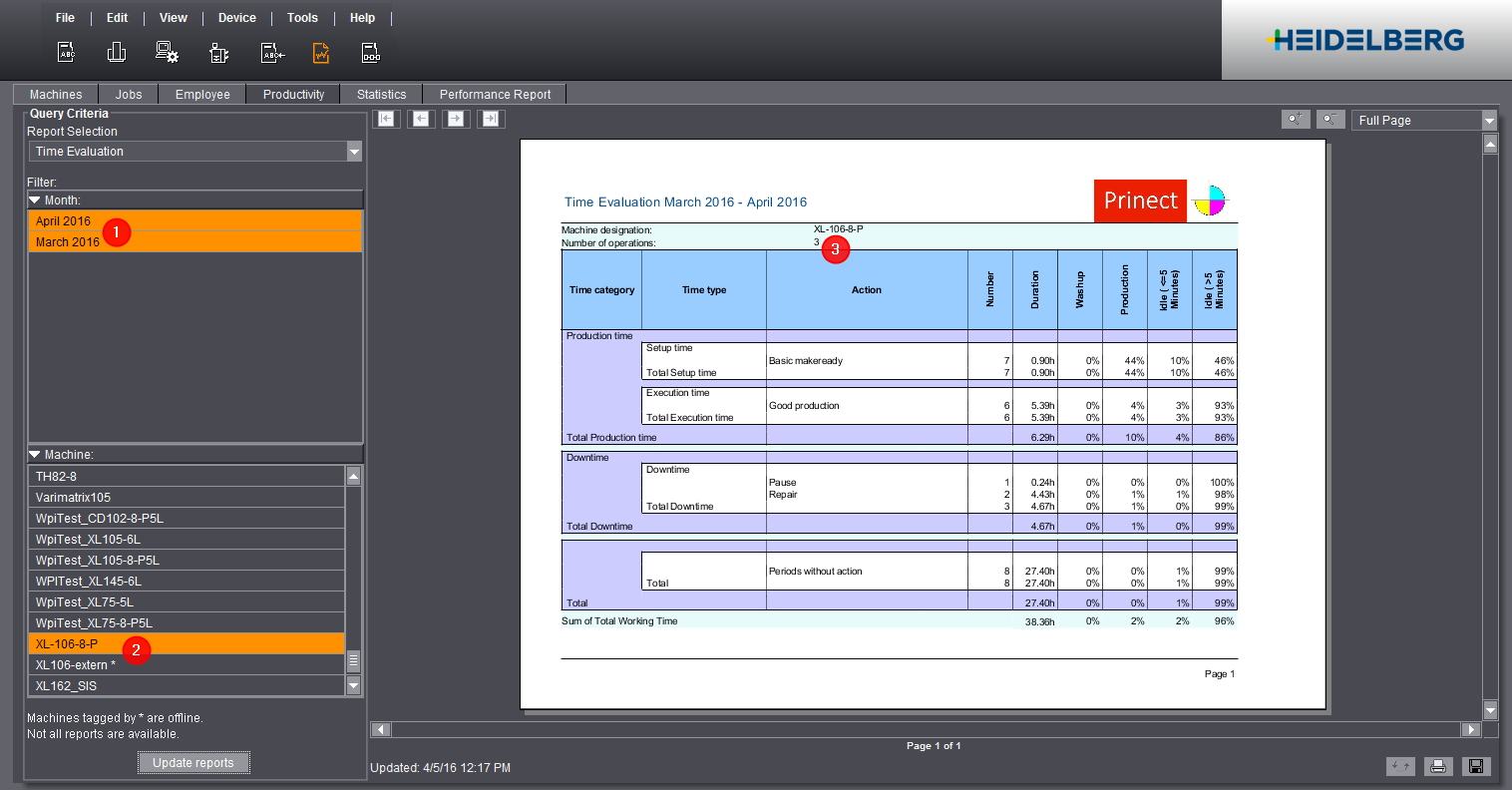

The Time Evaluation lists the production process at the selected machine (1) in the selected period of time (2). Only operations in the selected period of time are considered. The number of operations is indicated in the table header (3). A position after the decimal point indicates that an operation was not entirely completed in the selected period of time.

The Time Evaluation always refers to exactly one machine. The Time Evaluation occurs separately for each machine if you select more than one machine. With the arrow keys, you can select each of the Time Evaluations of the selected machines.

Note: The Time Evaluation is updated every hour. In other words: current times do not immediately appear in the Time Evaluation.

Upper Table Area

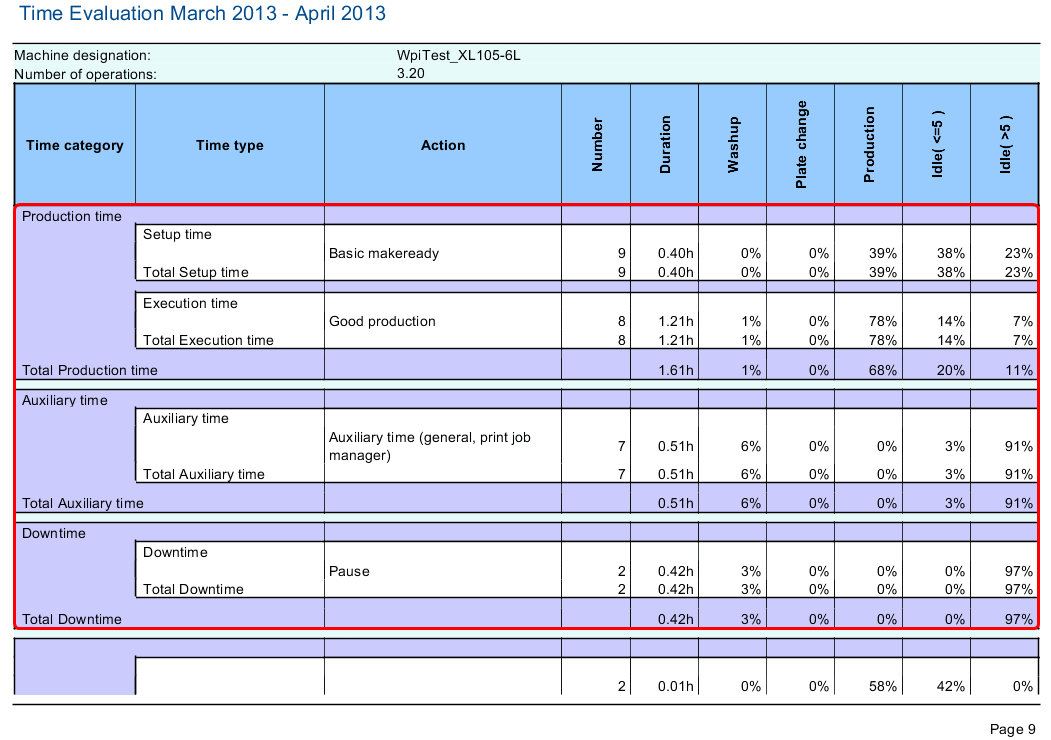

The upper area or table header of each machine-related Time Evaluation shows the share of recorded machine statuses in percent for each action and for each time type and time category. Explanation of each of the columns, see Explanation of the Columns.

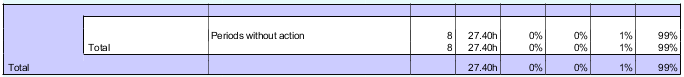

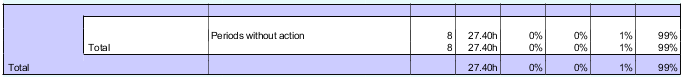

In the lower area or at the table end, all times without operation are listed. For possible reasons of a missing assignment, see Periods without action.

Note: The data for washing, plate change, production, idling <= 5 minutes and idling > 5 minutes are shown proportionally for each action and for each time type and time category in percent. "Washing", for example, can occur during basic makeready, or during "good production". The washing time is then evaluated in relation to actions.

|

Column Name |

Explanation |

|---|---|

|

Time category |

Time type group. The total time is indicated for each time category. |

|

Time type |

Indicates the time type assigned to the captured action. |

|

Action |

Name of the captured action. |

|

Number |

Number of occurrences of an action in the report period. If the start or end of the action lies outside the report period, this action is included. |

|

Duration |

Duration of all actions captured in the report period in industry hours. If the start or end of the action lies outside the report period, the time will be calculated proportionally. |

|

Washup |

Duration of the automatic washup programs. Note: If the washup occurs in parallel, the sum total of the percentages for the machine status times can be unequal to 100% |

|

Plate change |

Duration of the plate change for automatic plate change systems. Note: If the plate change occurs in parallel, the sum total of the percentages for the machine status times can be unequal to 100% |

|

Production |

Duration of good sheet and waste sheet production |

|

Idling <= 5 minutes |

Machine standstill or idling up to a period of 5 minutes. |

|

Idling > 5 minutes |

Machine standstill or idling for more than 5 minutes |

Explanation of Time Categories and Time Types

A description of time category and time type can be found in Explanation of Time Categories and Time Types.

Interdependency between Operation, Action, Time Type and Time Category

The above drawing shows how time recording at the machine is translated.

Operations (PDC messages) are messages that are sent at the machine. This can be done manually by the machine operator, or automatically by the machine.

The intervals between the operations are translated to Actions . A new action starts when an operation is reported. It ends as soon as a new operation is reported at the machine. An exception applies to operations that are not assigned to an action. As a rule, these are automatic operations. In this case, the time expired after the operation has been reported is added to the old action.

The actions are visible in the Employees of the machine operator later and indicate the duration of each of the activities.

Each action is assigned to a Time Type, and each time type is assigned to a Time Category. The classification into time types and time categories is to identify productive and non-productive times at the machine.

Some times may not have any assignment to a time category, time type and action. Unassigned times can all be found at the bottom of the table of each Time Evaluation.

A missing assignment can have the following reasons:

•The machine was switched on without processing a job or an operation being reported.

•Actions are not assigned a time type.

In this case, the action has already been set up, and you must assign it to a time type. See Editing/creating a time type.

•Actions have an assignment to a time type, but no assignment to a time category.

In this case, you must assign the time type to a time category. See Editing/creating a time type.

•No action is defined for the times.

Explanation: Operations (PDC messages) automatically reported by the machine (such as automatic washing) usually are not assigned to an action. This is correct because such messages are not to trigger a new action but are added to the previous one.

But if these messages are reported without reference to an operation, the times will not have any assignment. A typical example is the machine washup every weekend.

Note: Define a new action if you carry out work without reference to a job often. Proceed as follows:

1.Define a new action for this work (such as "Auxiliary times (general)").

See Defining a New Action.

2.Define a respective operation (PDC message) and assign the action defined beforehand to the operation.

See Creating a New Operation (PDC Message).

3.Assign the new operation to the machines where the action is to be recorded. The operation is visible at the machines only then.

See Assigning operations.

(4).If the operation does not appear at the machine, resynchronize the PDC configuration.

See Performing a synchronization.

The operation is now visible at the machine and can be reported by the machine operator. To correctly capture the times, the operation must always be reported before the work in question is started.