Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes

Configuring the data storage on the Prinect CP2000 Center for data exchange with the Prinect workflow

The following section describes how to configure the data storage on the Prinect CP2000 Center to be able to exchange data with the Prinect workflow. The procedures for configuring the data storage differ depending on which version of the CP2000 Center software is installed on the press control station.

1.First, you must open the appropriate software module on the press, i.e. on the Prinect CP2000 Center. The procedure differs depending on the software version installed:

From CP2000 Center version 37.6, you have to open the "DataControl" software module.

From CP2000 Center version 41.6, you have to open the "DataControl" data storage.

From CP2000 Center version 44.0, you have to open the "Workplace Interface" data storage.

In all three cases, the following view will open:

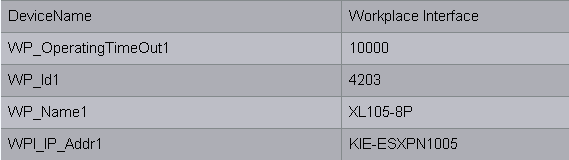

CDM devices | Prinect CP2000 Center |

|---|---|

Workplace ID | "WP_Id1" |

Device name | "WP_Name1" |

Name of the Prinect server | "WPI_IP_Addr1" |

Table of attribute assignments:

2.For the "WP_Id1" attribute, enter the workplace ID that you entered previously in Prinect Integration. See Workplace ID (6). In our example the workplace ID is "4203".

The press is uniquely identified in the Prinect workflow using this "WP_Id1".

3.Under the "WP_Name1" attribute, enter the device name. In our example the device name is "XL105-8P".

The device name was assigned when the machine was set up in the Device Assistant. See Device name (1).

4.For the "WPI_IP_Addr1" attribute, enter the computer name of the Prinect server. In our example this is "KIE-ESXPN1005". Once this configuration is complete, the connection between the press and the Prinect workflow should be fully established.

Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes