Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes

PPF List

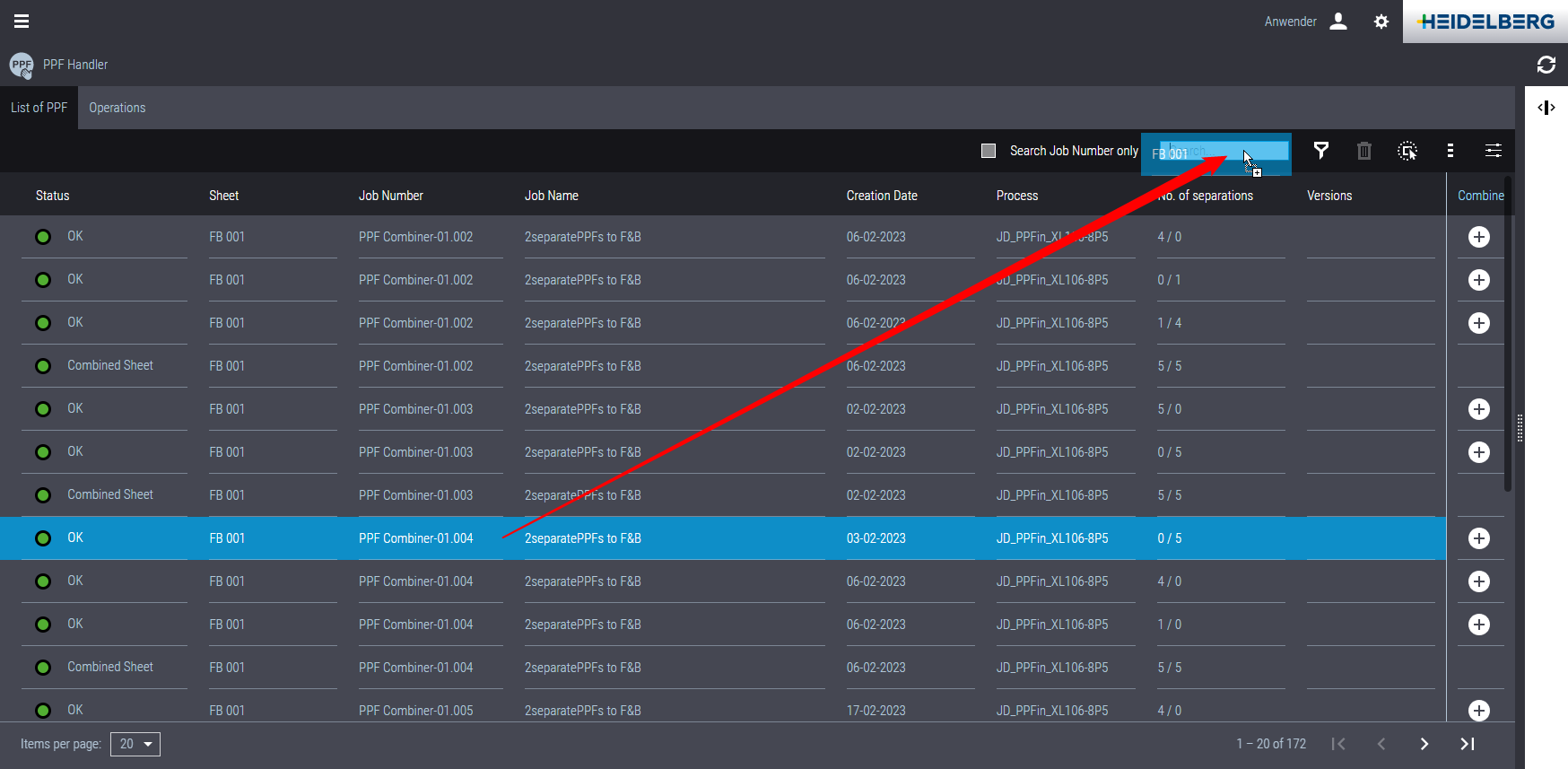

The following PPF files are displayed here:

•All imported PPF files, provided that they are not defective

•All PPF files which could not be automatically assigned to a job (only in a mixed JDF-PPF workflow).

•All PPF files not defined in the color tables of the Master Data Store (MDS) of Prinect Production.

"Combine" column

In the PPF list, you can click a "plus" icon in the "Combine" column. The icon will change to "minus". If the respective requirements are met, you can combine PPF files marked in this way into a common job. Thus, you can, for example, combine individual separations of a job the prepress system transmitted in single PPF files into a joint job. See Combine PPF files.

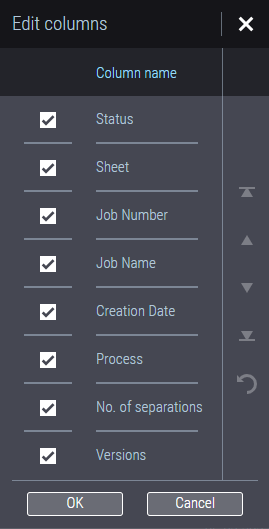

Clicking the "3-dot button" (1) opens the dialog "Edit column set":

This is where you can deselect/select single columns and set the order of the columns. The top item is displayed as the first (leftmost) column, the second item as the second column, etc.

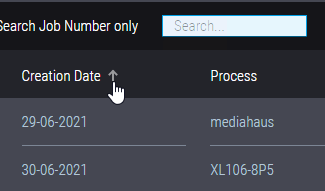

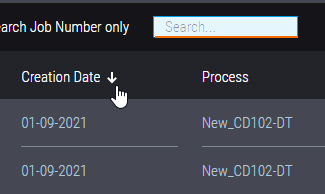

A small arrow appears next to the table header if you hover the mouse pointer over it. The arrow indicates the current sort order of the column.

Click the table header to reverse the sort order. This will also update the table view. The arrow then indicates the current sort order.

Multiple selection on mobile devices

You can click the "Multiple selection" button if you are operating Prinect Portal on a mobile device (tablet, smart phone). This lets you select several list items at the same time by touching them one after the other. This is a toggle button. Clicking it again will disable this function. This function works only on mobile devices.

The status of the incoming PPF files is shown here:

Process status | Explanation |

|---|---|

OK | This PPF file is OK. It can be processed in the Prinect Production workflow. The necessary operations are available at the Press Center. |

Warning | This PPF file is currently not available. This can be the case if important PPF attributes are missing, for example. You can then click the item in the PPF list and enter the missing attributes in the open preview window. Another reason can be that the Prinect Server where the PPF import hotfolder is set up is rebooting, or that there is a short-term network interruption. PPF file processing starts or continues automatically if the computer has rebooted or the network connection has been reestablished. In this case, manual intervention is not necessary but you can make manual changes to the PPF files. |

Error | A fault has occurred in this process. This status displays, for example, if the pertaining device (press) was removed from the CDM configuration or is no longer accessible in the network. PPF file processing is not possible in this situation. In this case, check the process configuration or your system environment. |

With the search function, you can easily find specific PPF items or operations in the PPF or "Operations" lists. To do so, enter text identifying the desired item in the search box. When you enter "XL105" for example, you will see all items containing the string "XL105". The columns "Status" and "Number of color separations" are not considered. Click the "x" next to the search item to stop the search and to display the complete list again.

Option "Search Job Number only"

With the option "Search Job Number only" enabled, the search is restricted to the "Job number" column. Searching for job numbers only may give significantly faster results if there are many PPF files in the system.

Add search text using drag-and-drop

You can also search for text by clicking a table item and dragging and dropping it on the search box. Then the list is searched for entries whose name components match parts of the term typed in the search field. Searching starts when you release the mouse button. If needed, you can edit the search text and trigger a new search.

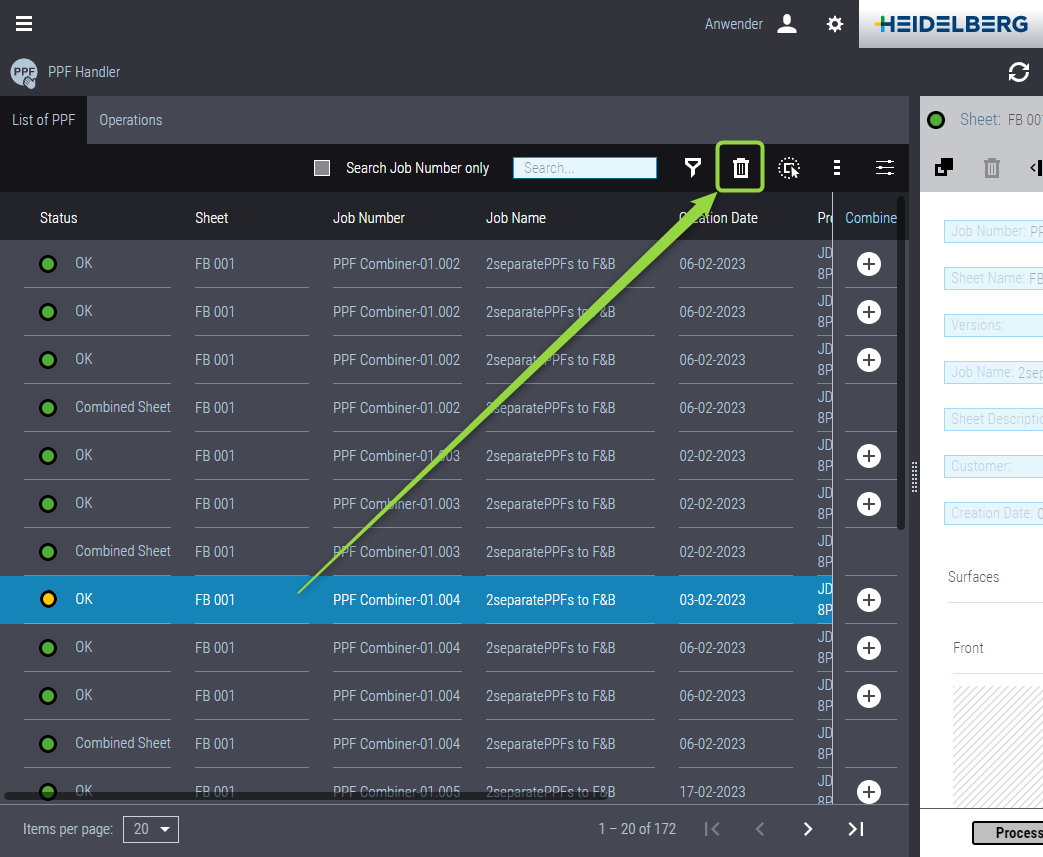

Delete PPF files

You can delete PPF files that have not yet been processed. Mark the respective list item and click "Delete"".

![]() Note: You cannot delete the PPF file if it is in the status "OK", which means the operations defined in the PPF file are in progress in Press Center.

Note: You cannot delete the PPF file if it is in the status "OK", which means the operations defined in the PPF file are in progress in Press Center.

PPF files will be deleted automatically if the pertaining print operation or print job was completed.

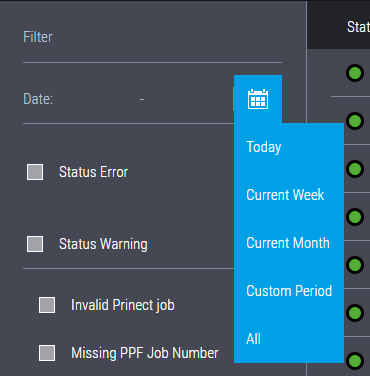

Click the "Funnel" icon (1) to enable the filter function. The filter criteria now display in the left window section. The filter function is primarily intended to find PPF items that cause processing issues and that may have to be edited manually. For this reason, the filter criteria — except for the date filter that lets you reduce the filtered list even more — comprise events that require intervention for processing to continue or that prevent the PPF data from being processed in Prinect Production.

Filter by date

Click the "Calendar" icon to choose a period of time to be applied to the filter.

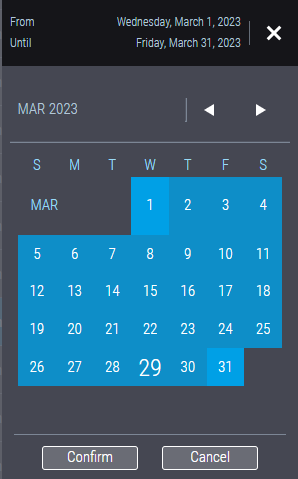

Here, you can select one of the suggested periods or "Custom Period". A calendar opens:

You can select a time period here. You can also select a time period spanning one month. To do so, click the start date, then set the desired month, and click the end date. The set period also appears as a text in the window caption. Click "Confirm" to choose the selected period of time as filter criterion. The date filter applies in addition to the other filter criteria.

Apply filter

Click "Apply" when you are finished with the filter settings. The filter criteria are being applied.

Restore unfiltered list

Click "Restore" to display the complete unfiltered list again.

![]() Note: When you close the Filter criteria settings and do not click the "Restore" button, the list will not be restored automatically but remain filtered.

Note: When you close the Filter criteria settings and do not click the "Restore" button, the list will not be restored automatically but remain filtered.

Close filter settings

Click the "funnel" icon again to close the filter settings area.

![]() Note: This is the only way to close the filter criteria settings.

Note: This is the only way to close the filter criteria settings.

Number of list items shown simultaneously

To the left below the PPF list you can set the number of list items shown simultaneously (1).

To the right, you can jump between the blocks of list items if there are more items than can be shown simultaneously.

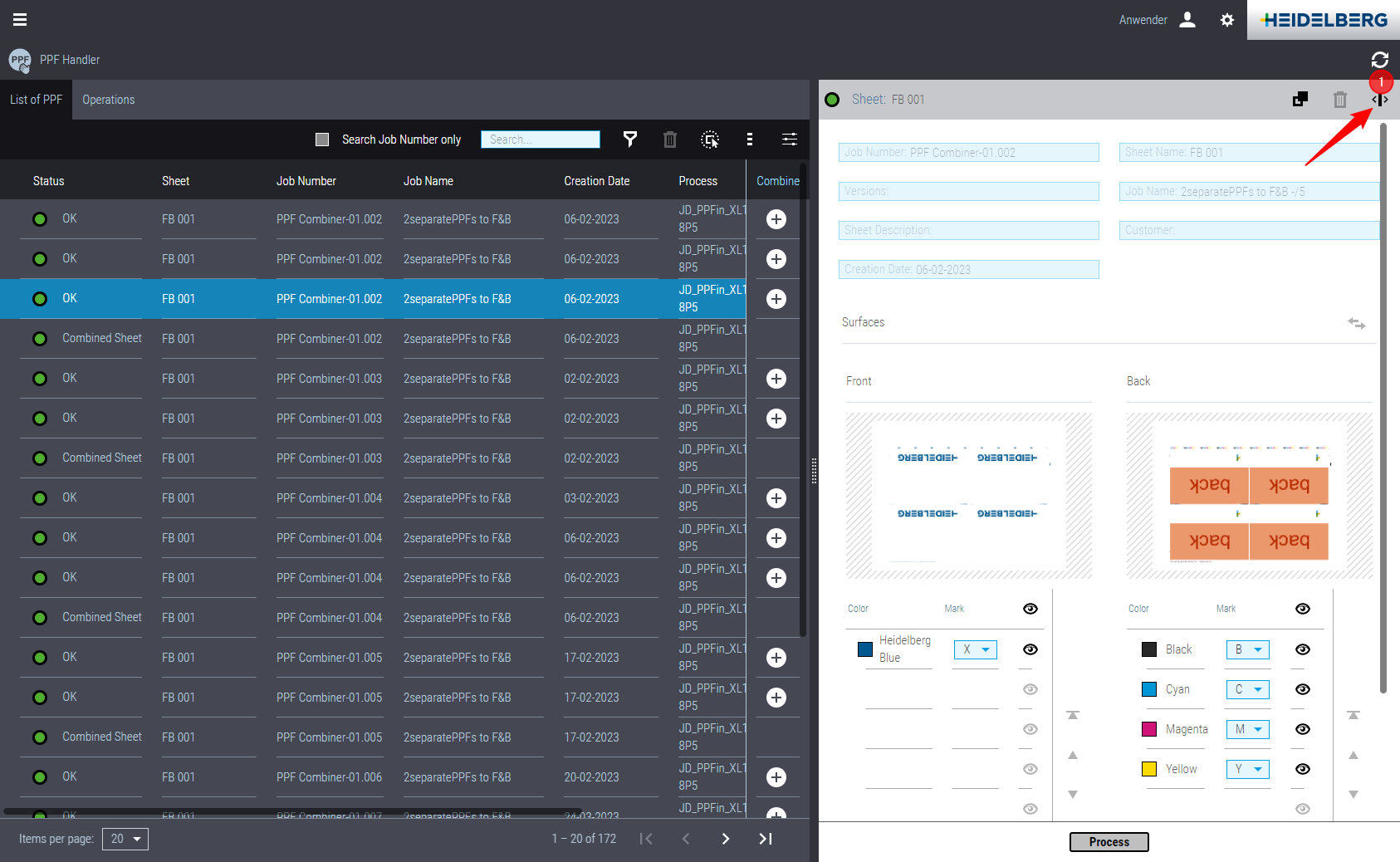

You can click a list item in the PPF and Operations lists to view the respective sheet::

The sheet previews and administrative job data of the item highlighted in the PPF input list are displayed here. You can make the following changes here if necessary:

•Changing job name or sheet name.

•Changing marks assignment and print order

•Deleting individual separations

You can click the "shrink" icon (1) to reduce the sheet preview to a narrow strip. The sheet preview opens again if you click the job again. When you click another item in the list, the sheet preview opens with accordingly updated contents.

Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes