The step is only enabled in the "Imposition" and "Automatic Imposition" work modes.

You can set the following parameters in the "Binding" step:

•Select the binding method

•Enable creeping and define values for it

•Enable automatic bottling

•Define a gripper margin for front or back fold

•Define cover bonding for residual glue (web)

•Define a glue line (web)

•Define defaults for automatic gap computation

(see also Overview of Gap Computation)

•Assign cut blocks

Prinect Signa Station automatically defines the pagination and any necessary creeping for the selected binding method (pagination depends on the folding scheme/folding rule you selected).

The trim for the pages at the back margin is set to the value defined in "Preferences > Trim ... in routing margin" if you use a binding method that includes a routing margin. Normally, the routing margin should not have any print data.

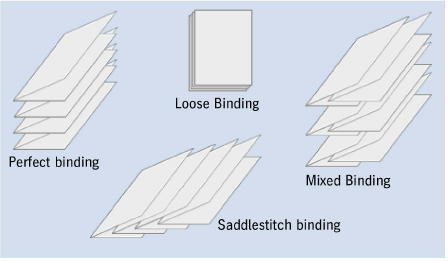

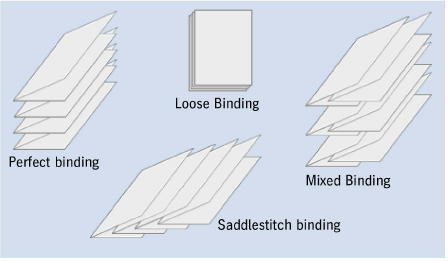

In perfect binding, the folded sheets are placed on top of each other, milled off at the back and glued.

Note: Automatic gap computation generates a gap between the left and right page that is equivalent to the maximum routing margin.

In saddlestitching, the folded sheets are nested. As a result, the final page number of the assembled page not only depends on the folding scheme selected, but also on the size of the publication.

In this binding method, the application automatically pairs up the highest and the lowest page numbers and then calculates the number that each individual page will really have.

Note: Automatic gap computation set the gap between the two-page spreads to 0 mm.

Note: In the "Product Part" step, you can also set the "Binding Type for Gluer" that is written to the output JDF and can be used in postpress for machine presetting. This setting has no impact in Signa Station.

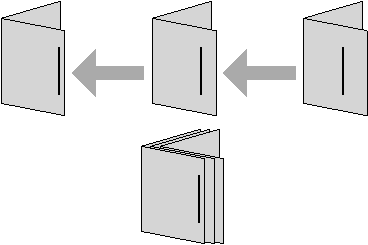

In the "Come & Go" binding method, the first and last book block are printed on one folding sheet, the second and second last block together, then the third and third last, etc. The folded sheets are stacked one on top of the other until the middle is reached or passed. The last fold between the two blocks is not made. Instead the sheets are cut. Now both piles of blocks are placed one on top of the other. In this way, your book is produced.

Additional 1ups of parts of a book can be produced by utilizing a folding sheet to print additional book blocks that are also cut off and then gathered with the other blocks. The aim is to produce smaller folding sheets (less creeping), to fold less folding sheets and to save a cut on the cutter by using the separation cut on the folding machine. This process is used often for small-format books (soft cover).

Page numbering is the same as in saddlestitching. Creeping values, on the other hand, are similar to those in perfect binding. However, the creeping values depend on the folds done and, for that reason, are not 1:1 identical. This means that different values are calculated when the binding method is changed. For example, in an F08 scheme in Come & Go, creeping of the two folding sheet halves would be equivalent to creeping of an F04 scheme in perfect binding.

Note: Automatic gap computation generates a gap between the left and right page that is equivalent to the maximum routing margin.

This option also allows you to image two book blocks on one folding sheet. One block has ascending page numbers, the other descending page numbers. In other words, mirror-inverted sheets are produced, with two whole books being imaged. This mode is used if the plates would have been necessary anyway because of the number of sheets or if rotation of the first folding sheets would result in an inaccurate production. Generally, closed and open sides of the folding sheets alternate.

Note: If you create a product part in this binding mode, the number of pages is automatically doubled and twice as many folding sheets created. For example, to print a book with 48 pages, enter 48 pages as your page total. You need three folding sheets for this. Prinect Signa Station, however, doubles this number to 96 pages and 6 folding sheets.

Automatic gap computation generates a gap between the left and right page that is equivalent to the maximum routing margin.

In this binding mode, a stack of sheets can be divided into two parts after printing, with one part consisting of the upper half of the page numbers and the other of the lower half. For example, in a 16-page book, one stack has pages 1 thru 8 and the other stack pages 9 thru 16. For this to be done, you must create a folding scheme where the page numbers make allowance for this, e.g. after folding for two pages, 1-3 (front), 4-2 (back).

Note: Automatic gap computation generates a gap between the left and right page that is equivalent to the maximum routing margin.

This binding method includes different binding modes, namely perfect binding and saddlestitching.

For example, three folding sheets are assembled to one book block with saddlestitching. Afterwards, the book blocks are compiled to one book with perfect binding or thread-stitching.

Note: Automatic gap computation set the gap between the two-page spreads to 0 mm.

In the Loose Binding mode, you can create all the gaps the same, at least on the right and left. This means that all the sheets are the same, that they are not folded just cut, for example, punched sheets in a loose leaf binder.

Note: Automatic gap computation divides up the available space evenly between all gaps.

In a publication with thread-stitching, the folded book blocks are stacked on top of each other, with the sheets bound by thread.

This method is analog to perfect binding but there is no routing margin.

In a publication with a leaflet fold, the pages will not be cut. This means that the spacing between the pages must not change.

Note: Automatic gap computation set the gap between the two-page spreads to 0 mm.

This setting is for books in Arabian-speaking countries. In such countries, books are opened from left to right and read from left to right. You must create a special folding scheme for this.

The function is not suited for the "Come & Go", "Come & Go Two Books" and "Cut and Stack" binding methods. The setting switches automatically to "Perfect Binding" if you select one of these binding methods.

The pagination of a 36-page publication is affected as follows when you enable the option:

•"First and Last"

The cover has pages 1, 2, 35, 36

•"First"

The cover has pages 1, 2, 3, 4

•"Last"

The cover has pages 33, 34, 35, 36

This function now makes it an easy matter for you to place cover pages, for example, to the beginning or end of a custom PDF document.

In addition, automatic mechanisms are handled as follows:

•The folding sheet concerned is ignored in the calculation for creeping.

•The folding sheet concerned will not have any collating mark. Collating mark "1" will be placed on the second folding sheet.

•The folding sheet concerned is ignored in the "sort for bookbinding" function.

Sort Folding Sheet for Bookbinding

Bookbinders generally want that smaller folding sheets (half sheets, quarter sheets or even light-weight sheets) are not at the end of a book block. This function automatically repositions the sheets accordingly.

You can also enable this option manually in Sort Folding Sheet for Bookbinding using the context menu in the "Schemes" step > "All Folding Sheets" if a folding sheet is selected.

Note: In the "Schemes" step > "Gaps and Master Pages" and "All Folding Sheets", red font draws your attention to the fact that the option was already enabled.

Twin lay jobs are those where two different products are processed in one scheme. The procedure used so far tried to obtain a resulting scheme by nesting two schemes. For this purpose, the horizontal gap was extended in its center until the second scheme fits in there completely. But since the sheet must be folded altogether, all gaps of both schemes must match exactly. Assembling two schemes to obtain such a result proved too complex in practice.

The procedure of version 13 and later uses a different approach. A folding scheme contains two products. This method has already been used in the "Come & Go" binding method, i.e. "Come & Go" is a special variant of the twin lay method. But there is a restriction: the folding sheets of both products cannot be moved due to color or other requirements. It is not possible in this way to combine folding sheet 1 of product 1 and folding sheet 3 of product 3 on one press sheet because they contain the same spot color, for example.

The twin lay method in Prinect Signa Station meets these demands universally. This requires that you can split a folding scheme into a maximum of two sections and that this division is always horizontal. You enable the "Twin Lay" mode in the "Binding" step of the Assistant/Product Part Inspector. You can select this option only with allowed binding methods (at present, perfect binding, saddlestitching and thread-stitching). The "Change Section Order" button in the "Schemes" step becomes operable when the Twin Lay option is enabled (see Section Handling ).

For saddlestitch-bound publications (such as magazines), the paper thickness makes the inner pages shift outward (i.e., away from the spine). If the publication is trimmed after binding, the inside pages will have narrower outer margins than the outside pages. The same is true for perfect binding when large sheets with many pages must be folded often.

This schematic diagram shows how the required value for creeping is determined in saddlestitching.

Creeping Off

The function is disabled and ignored.

The creeping values are calculated automatically from the paper thickness if you select this option. You can generate or modify the paper definitions in the "Plates" step or in "Papers (Printing Materials)" in the "Jobs & Resources" menu > "Resources & Machines". See also Papers (Printing Materials).

The function makes automatic creeping in X and Y direction possible.

•Creeping by

You can choose between "Offset" (default) and "Scale". With scaling, the pages become bigger or smaller depending on their position in the scheme to stay the same at the back margin and match them to the nominal position on the outer edges.

•Paper Thickness Factor

The paper thickness is multiplied by this factor to get the creeping you want for each sheet.

Enable this option if you wish to enter your own inner/outer creeping values. The values refer to all the folding sheets in the product part. The data for "Inner" and "Outer" always refer to the first scheme of the product part. The program calculates creeping per sheet from these values and applies it to the entire product part.

•Dual Direction Creeping (see "Automatic")

•Creeping by (see "Automatic")

•Creeping Value Inner

This is where you enter the value by which the innermost pages of the first scheme have to be offset to compensate for their creeping.

•(Creeping value) Outer

This is where you enter the value by which the outermost pages of the first scheme have to be offset to compensate for their creeping. The difference between the internal and external adjusted margins is the creeping margin. By entering positive values, you will shift the pages outward; by entering negative values, you will shift the pages toward the spine.

The distances between all the other pairs of pages in the book will be calculated according to these extreme values. The creeping margin values are related directly to the page spacing you have set in the scheme, see also Folding Scheme Editor . These values will be added to or subtracted from the page spacing.

For more details about enabling creeping for a single page, see Creeping.

The scheme used determines whether automatic creeping is possible or whether manual creeping is necessary.

Generally, the program can calculate the required creeping margin values itself.

AutoBottling

Remember the following conditions when you enable this function:

•Binding Methods

Automatic bottling is not allowed with "Come & Go" and "Cut & Stack" binding methods.

•Folding sheet

The folding rule must end with a cross fold, e.g. "x1Y1", and may not have a minus sign.

•You may not make any changes or corrections to the scheme after you enabled the automatic function.

•In web presses with ribbons, combinations with single pages and 3/4 pages may result in problems.

•"AutoBottling" must be disabled if you use the scheme "F16-11_li_4x2".

•Fold types "zigzag" and "letterfold" can be problematic.

•Pagination

The "Accordion Fold" pagination mode may not be selected in the Folding Scheme Editor.

More information about "bottling" and what manual corrections you can make can be found in Bottling .

Gripper Collator / Cover Bonding / Glue Line

Normally, a strip of paper/material is used to pull the folding sheets on to the saddle if a saddlestitcher is used to collate the sheets. The position of this strip on the sheet depends on the folding sheet scheme and basically means that the folding scheme is slightly asymmetric on the paper sheet.

Prinect Signa Station's automatic gap computation includes the values you enter for this option and calculates all the gaps so you have the correct front and rear gripper fold after folding.

•(No) rear fold/front fold

There is no gripper margin for the saddlestitcher or there is a page offset for a gripper margin for the rear or front fold. You must enter the values in "Size of Gripper Margin".

This is where you define the size of a page offset for the rear or front fold for the gripper margin of the saddlestitcher.

Note: When this function is set, the values display in the "Schemes" step. In addition, the function can be seen.

Only displays if "Show check items for cover bonding and glue line" is enabled in "File > Preferences > User Interface > General".

In "Cover Bonding", space is added to the folding sheet paper. In book production, this additional space must be created at the lower edge of the cover so that residual glue can be absorbed when gluing the cover to the book and that it does not flow into the pages.

•None

•On the First Folding Sheet

Paper is added to the first folding sheet of the product part.

•On the Last Folding Sheet

Paper is added to the last folding sheet of the product part.

Only displays if "Show check items for cover bonding and glue line" is enabled in "File > Preferences > User Interface > General".

A glue line is needed when producing booklets with web presses. A glue line is automatically applied before folding. This serves the purpose that no further gluing is needed after folding.

The folded double pages are glued together at the sides along a narrow strip in the back margin. This line is not noticed when leafing through the pages.

There should be no color in the glue line as this could impair adhesion.

This can be done in one of the following ways:

•By Moving

You can move the content of each page affected away from the back margin by the value set in "Glue Line Width".

•By Scaling

The visible page content is retained and scaled (made narrower) so that the glue line in the back margin of each page is kept free by the value set for width.

•By Clipping Only

The page bleed becomes smaller.

•Outermost Pages Only / Include Inner Pages

Normally, the glue line is defined on the outermost pages. However, in certain production conditions, it may be wanted also on the innermost pages (for example, to glue a cover to a booklet). Choose the option accordingly.

•Glue Line Width

Enter the width you want for the glue line.

Parameters for Automatic Gap Computation

Note: See also Overview of Gap Computation

Automatic gap computation

This setting lets you select where the setting for automatic gap computation comes from. If "Use for JDF Import" is enabled in a product part template, then during a JDF import with a product part template the setting for automatic gap computation from the Preferences is not used but the setting from the product part template.

In this way, for a specific job you can switch between the Preferences and the product part template as the source.

If automatic gap computation is enabled, it is no longer possible to specify the gaps manually in the "Schemes" step. The gaps are calculated automatically when a new scheme is added. If automatic gap computation is not to be done for a scheme, you can disable it for the selected scheme with "No Automatic Gap Computation" in the "Schemes" step.

Routing margin

•This displays the default value for a routing margin. After you enable the "Use routing margin" option, the value is applied in the product part and you can also change it manually in this box.

The value is taken from the preferences in "File > Preferences > Defaults > Routing Margin Min.".

Use this option to define whether or not a routing margin will be included. You can disable the function as you may want to impose a job with thread-stitching as a job with perfect binding (there must be no routing margin in thread-stitching).

Note: Automatic matching of the routing margin is ignored if special master pages are defined in a job as this would otherwise give you incorrect results.

Max. Head Trim/Max. Foot Trim/Max. Gap

The value entered is used for the automatic calculation of the gaps (in the "Schemes" step) when you check this option.

The value for Max. Head Trim only affects the page head, the value for the max. gap all the gaps. The gaps are created only up to the size entered, even any larger head trim, if Max. Gap is enabled. This means that the folding sheet can be smaller than the paper.

Analog to the maximum head trim, during automatic gap computation the gap at the foot of the page is set up to the entered value as a maximum. This can be necessary if you are working with a saddlestitcher/perfect binder that aligns the signatures on the foot or, in the case of multiple 1ups, with high quantities in finishing.

Remember that the extra space in the "Master Pages" step is taken to be the minimum gap and the maximum gap is added to this. The automatic gap is used if you disable the maximum gap. In this case as well, remember the values you entered in the Preferences > "Defaults" tab.

Gaps between a two-page spread such as routing margins are not affected by this.

For example, if the gap at the head is always to be exactly 10 mm, then enter 5 mm in "Master Pages > Trim Allowance for Pages > Top", set Max. Head Trim to 0 mm and check the box. The head trim is now automatically exactly 10 mm when the gaps are calculated automatically.

In the "Imposition" and "Automatic Imposition" modes, it is also possible to customize the cut block to meet your different needs.

Cut blocks that are defined as described below are written to the data for a CIP3 or JDF output and as a result their data can be used by cutters.

Cut blocks are shown as a "green line" in the graphic window.

To pages/1ups

The single pages on a folding sheet automatically become cut blocks.

This can be a good idea if a scheme with the same page numbers, e.g. when you create postcards, was selected. Generally, however, the "Montage" mode covers this type of production.

To folding sheets

Folding sheets including their margins automatically become cut blocks.

This is what you normally want and is the default.

To scheme

Only the scheme without the folding sheet margins becomes a cut block.

The margins must not be in the cut block if the folding sheet is to be trimmed to size before folding.