Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes

![]() Prerequisite: The following requirements must be met to operate the Plate Pilot:

Prerequisite: The following requirements must be met to operate the Plate Pilot:

•To generate the required planning data, an MIS (Management Information System) and/or the Prinect Scheduler must be available in the system environment.

•To use network signal lamps, such lamps must be installed and accessible in the network (WLAN) of the Prinect system environment.

With the Plate Pilot, it is possible to systematically put together printing plate stacks for just in time printing.

CTP devices

The Plate Pilot supports all imagesetters that are connected to Prinect Production directly via Prinect Shooter 2 (TIFF-B export) or, if it is a third-party device, as an "external CTP device". See Add External CTP Device. When configuring CTP devices controlled via a Prinect Shooter 2, all the clusters containing this CTP device or the TIFF-B export devices have to be configured alike for the Plate Pilot. In other words, "Plate Pilot active" must be enabled, and the respective parameters must be configured.

![]() Note: In "Administration > System", you can switch between manual operation and operation with the Plate Pilot, if needed, in the context menu in the "FormSetter" cluster view for directly connected CTP devices (not for TIFF-B outputs). See also Configure CTP devices for Plate Pilot or manual operation.

Note: In "Administration > System", you can switch between manual operation and operation with the Plate Pilot, if needed, in the context menu in the "FormSetter" cluster view for directly connected CTP devices (not for TIFF-B outputs). See also Configure CTP devices for Plate Pilot or manual operation.

In a first step, the ImpositionOutput sequence generates the Tiff-B files required for exposure and collects them instead of forwarding them to the imagesetter immediately. When all the Tiff-B files belonging to a print job have been generated, they are put together to a "virtual plate stack" and sorted to match the print unit order. The assignment to a plate stack or the creation of a plate stack is based on the following criteria:

•the operations are scheduled for a specific press

•the print operations follow each other without gaps

•the maximum number of possible plates for the intended plate trolley is reached (a new plate stack is generated in this case)

•a minimum lead time prior to the scheduled print date has been reached, i.e. all plates must be imaged after the lead time has expired, and the plate cart must have been transported to the press

•a minimum time offset to the scheduled print start has been reached.

The plates are exposed shortly before the scheduled date of the "Print" operation. The plates can then be transported to the press as a "real plate stack" on a plate trolley. Thanks to the sort order, the plates can be mounted into the print units one after the other, and printing can take place at the scheduled date.

![]() Note: There will be no scheduling of print operations in Prinect if an external Prepress system is used. In this case, PlatePilot displays all print operations created in the last 4 weeks.

Note: There will be no scheduling of print operations in Prinect if an external Prepress system is used. In this case, PlatePilot displays all print operations created in the last 4 weeks.

Barcodes

Barcodes are printed on the plates and can be read at the press in order to automatically identify the plates. The barcodes are printed on the plates as marks and also contain operation information such as JobID, sheet, color, etc.

![]() Note: These barcodes can also be used to control Plate Management Systems (Nela Plate Indexer).

Note: These barcodes can also be used to control Plate Management Systems (Nela Plate Indexer).

For CTP devices, you can configure the printing of pallet sheets for printing plate pallets on a Windows system printer; to do so, go to "Administration > Device configuration > devices". For CTP devices, the pallet sheets provide information about the stacks of plates generated by Plate Pilot, such as whether the stacks of plates are fully exposed. See also Defining Windows printers on the Prinect server and Enable / disable automatic pallet sheet printing for pallet change.

Network signal lamps

The current state of CTP devices and plate trolleys can be indicated over a long distance with controllable signal lamps installed in the press room. In this way, you can easily detect that a plate trolley is completely filled and needs to be transported to the press or replaced with an empty trolley.

User Interface

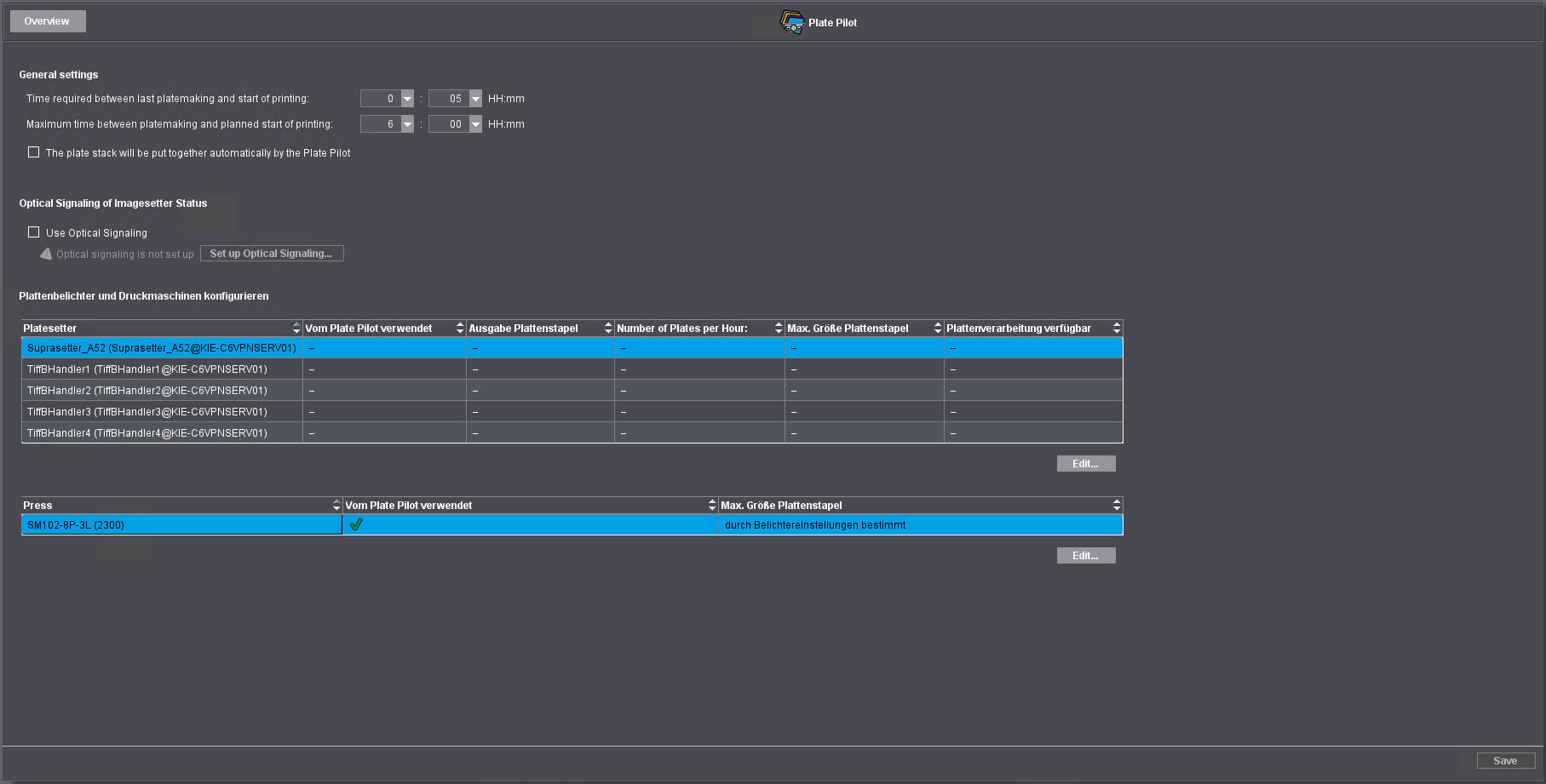

The user interface of the "Plate Pilot" is part of the Prinect Portal (WEB UI). Configure the system-wide settings for the Plate Pilot in the Administration area of the Prinect Cockpit.

Privacy Policy | Imprint | Prinect Know How | Prinect Release Notes