What's New?

In this chapter, we would like to highlight to you briefly the main enhancements and changes in the current Prinect Signa Station. The blue links will lead you directly to more details on the topics.

What's New in Prinect Signa Station 2020.10

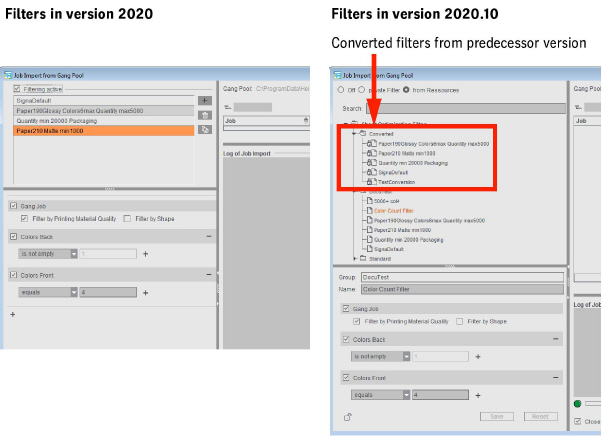

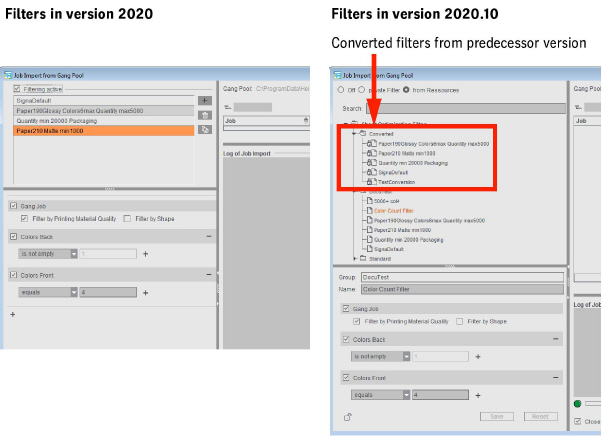

Gang tasks and filters as resources

The tasks for the automated processing of gang jobs and the filters for job import from the gang pool are now both managed in the resources. If you have a large number of gang tasks and filters, this makes it possible to display them in a clearer overview because these can then be sorted in different groups. In this way, administration is made simpler and errors as a result of a wrong selection are reduced.

Two new editors are available for creating gang tasks and filter rules:

See Task Setup Editor and Filter Editor for details.

After the update to version 2020.10, any existing gang tasks and filter rules are converted automatically only once to resources when Prinect Signa Station first starts and are sorted to the relevant resource group. The gang task group generated in this way is set automatically as the "Current Task Parameter Group" in the "Planned Gang Jobs" dialog (see Planned Gang Jobs for details).

Filters in "Job Import from Gang Pool":

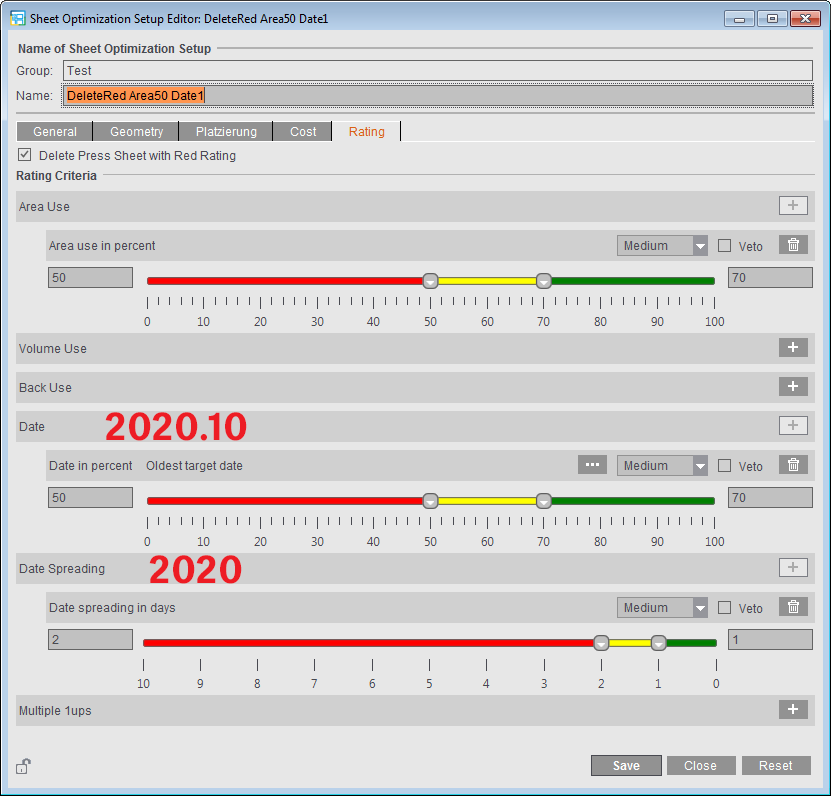

Modified rating criteria for optimization

The rating criterion "Date Spreading" introduced in version 2020 was replaced by the rating criterion "Date":

"Date Spreading" continues to be shown and assessed in the case of existing sheet optimization setups where "Date Spreading" is enabled as a rating criterion. It cannot be enabled in new parameter sets or if the rating criterion was removed from an existing parameter set.

The "Date" rating criterion lets you assess the press sheets based on a uniform target date of the jobs. If required, you can define a period, "target date + x days", using the button with the three dots.

You can find more details in: "Rating" Tab.

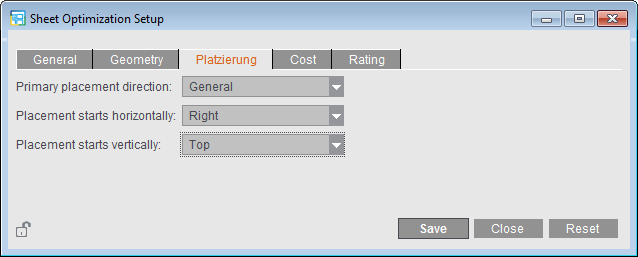

Variable setting for placement

Up to now, the bottom left corner of the press sheet was always used as the starting point during optimization. Only for orientation could you make a difference between "General", "Horizontal" and "Vertical". This setting is now set in the new tab, "Placement", as the "Primary placement direction". This is where you can now also set the sheet corner that is to be used as the starting point of optimization.

You can set this either for a specific job in the Sheet Optimization Setup or as a default in the optimization data resources or the plate template resources.

Simpler editing of gang parts in the input list

In the "Input List for Sheet Optimization", you can now edit gang parts using the context menu ("Edit Delivery Quantity", "Set Orientation to ...", etc.) irrespective of the column in which the cursor is currently located.

Enhancement of the geometry data for sheet brakes

The width of the sheet brakes (vertical lanes) and the number and width of the horizontal lanes have been added to the "Geometry" group in the Sheet Optimization Setup.

At present, sheet optimization without a layout does not support horizontal lanes.

See "Geometry" tab for details

New option, "Use for JDF Import". If this option is enabled in a product part template, then during a JDF import with a product part template the setting for automatic gap computation from the Preferences is no longer used but instead the setting from the product part template. In this way, for a specific job you can switch between the Preferences and the product part template as the source.

In the case of new product part templates, the option is first disabled in order not to change the old behavior.

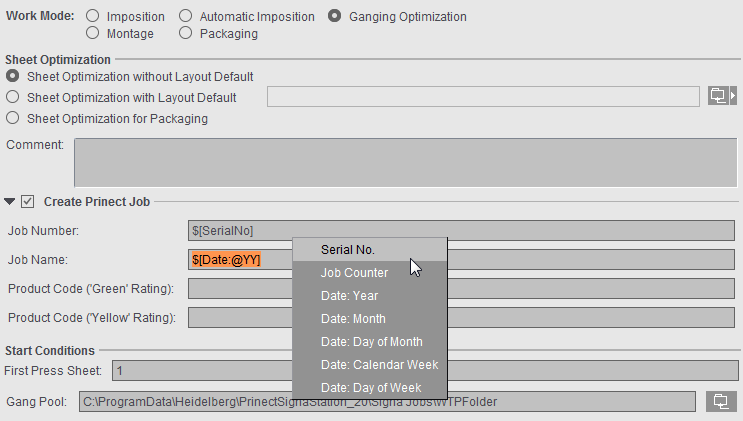

New function, "Create Prinect Job" (makes it possible to create a Prinect job during manual creation of a gang run form)

Note: Only in the "Ganging Optimization" work mode.

When gang run forms are created via the Prinect Signa Station Gang Server, it is possible to use product codes. As a result, various functions are triggered in the workflow:

•Job creation with matching process network via Smart Automation

•Automatic start of processing

•Definition of the procedure instructions for the matching gang run form based on placed gang parts

As of version 2020.10, you can also enter product codes when creating a gang run form manually in Prinect Signa Station and output the gang run form through the same way. In other words, a layout is generated directly in a Prinect job based on the same pattern as in automated processing by the Prinect Signa Station Gang Server.

For that reason, you can fill out the "Job Number", "Job Name" and "Product Code ('Green'/'Yellow' rating)" boxes either in the product part template or, like in version 2019, in the gang task.

When defining a gang task, select whether the data will be taken from the assigned product part template ("Job Data from Template") or whether you wish to define the data independently of the template and directly in the task ("Job Data from Task"). It is necessary to define the data in the task if, for example, different gang tasks are to use the same product part template. In this case, separate product part templates that only differ in the job data do not have to be created for various gang tasks.

More details can be found in Create Prinect Job.

"Job Data from Template" is the default setting when creating new gang tasks. When older gang tasks are opened, "Job Data from Task" is set because no definition was then possible in the product part for these tasks.

Password protection for preferences and resources

To prevent unwanted changes to the resources, you can lock single resources or whole resource groups. In earlier versions, however, these locks could be removed again by each user without restriction. You can now assign a password in the Preferences for locking and unlocking resources.

See Password for locking and unlocking resources

Like in the resources, you can also assign a password for all of the Preferences to prevent unwanted changes. If the correct password is not entered when opening the Preferences, the buttons for saving and resetting are disabled.

See Password for editing the Preferences

When shifting folding sheets in the graphic view, the snap behavior has been fully revised. Up to now, the folding sheet to be moved snapped into place only if it abutted a corner of an adjacent folding sheet. It did not snap into place if it was moved to the edge of another folding sheet.

Now it is possible to snap into place on the edges of all folding sheets and snap lines placed on the press sheet. That is why it is also possible to align objects to each other even if they do not lie directly side by side on the press sheet.

In addition, a "magnetic line" in X and/or Y direction is drawn across the whole paper while moving the object during the snap process.

In the "Packaging" work mode, the settings for positioning cutting dies have been revised substantially.

The settings for the positioning of cutting dies are now kept permanently. This allows the positions of the cutting dies to be restored automatically after changes to the job (e.g. change in paper size).

See Cutting Die File and Main Settings for details

What's New in Prinect Signa Station 2020

You can choose between three different designs for the user interface. You can select the one you want in the Preferences in the "General" tab. You must restart Prinect Signa Station after you make your changes.

See Concept of the User Interface and Color Scheme for details.

The detailed user administration has been dropped in Prinect Signa Station because importing the user data can take a great deal of time and generally only "PrePressAdministrator" users work in Prinect Signa Station. Accordingly, it is no longer necessary to log in and out of Prinect Signa Station.

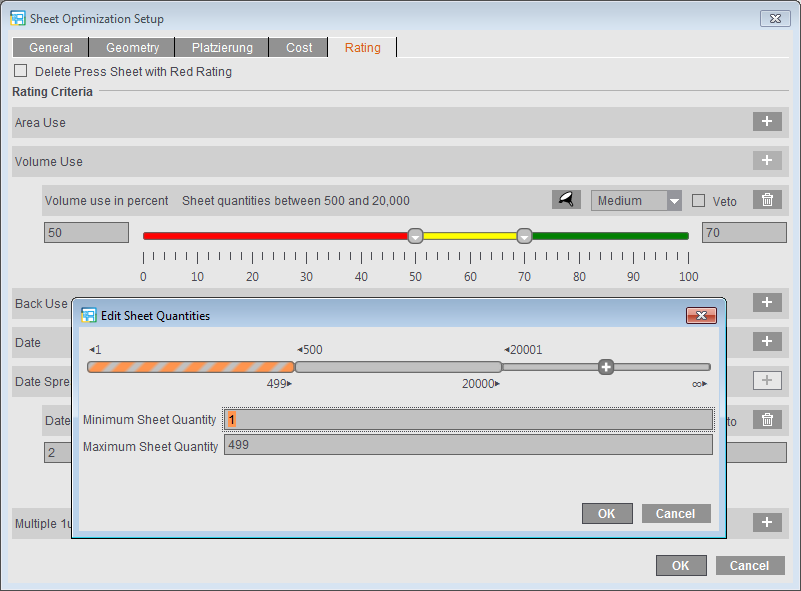

Enhanced rating criteria for optimization

The rating criteria introduced in version 2019 were enhanced. In addition to Area Use, you can now also set the following criteria:

·Volume Use

·Back Use

·Date Spreading

·Multiple 1ups

In the "Rating" tab in Sheet Optimization Setup, you can set the various rating criteria that can be weighted in 5 grades and combined with each other. Volume Use and Multiple 1ups can also be differentiated by sheet quantity or delivery quantity.

If you have a combination of several criteria, the "Veto" option makes sure that the status for the overall result (traffic light color) cannot be better than the status of a single result.

These settings are included during optimization. The results of the rating criteria display in "Results" and in the HTML report. In the list view of the press sheet, you can add the ratings as additional columns to the table.

You can find more details about the quality criteria in: "Rating" Tab.

Note: For Sheet Optimization without Layout Default, the percentage for the rating result refers to the whole press sheet. For Sheet Optimization with Layout Default and Sheet Optimization for Packaging, the percentage refers to the default layout or cutting die. In other words, a completely filled layout produces, for example, an area utilization of 100% even if the whole press sheet was not used. This rating, varying according to optimization type, is applicable for all quality criteria except for date spreading.

Optimization settings: Cost-based or quality-based optimization

There are basically three different ways for controlling optimization, depending on the priorities that you have:

•"General > Only One Press Sheet": off

"Rating > Delete Press Sheet with Red Rating": off

·Optimization runs essentially on a cost basis.

·All gang parts are placed.

·Set quality criteria are assessed and the results shown, but they have only a lower priority during optimization.

•"General > Only One Press Sheet": on

"Rating > Delete Press Sheet with Red Rating": off

·One press sheet is generated.

·Of the available gang parts, those gang parts are selected that will give you the best possible overall rating, matching the enabled quality criteria and taking the cost into account.

·Gang parts that are not used are subsequently located again in the gang pool.

•"General > Only One Press Sheet": off

"Rating > Delete Press Sheet with Red Rating": on

·Based on the quality criteria and taking the cost into account, several press sheets may be generated because you try to process all the imported gang parts if possible.

·If a sheet has a red rating in the overall rating or in a criterion defined as "Veto", the sheet is rejected automatically and the gang parts are returned to the gang pool.

Costs are included also during optimization based on quality criteria. However, it is possible that the costs determined are higher than with a pure cost-based optimization.

If "Use Optimization Parameters from Plate Template" is enabled, it is still possible to work also with the rating criteria.

You can find a detailed explanation in: Usage of the Optimization Settings

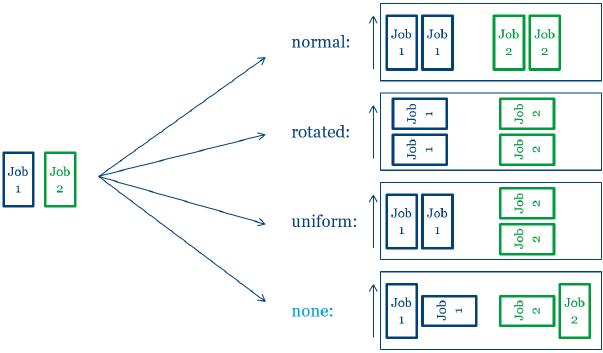

Orientation (orientation of the articles on the sheet)

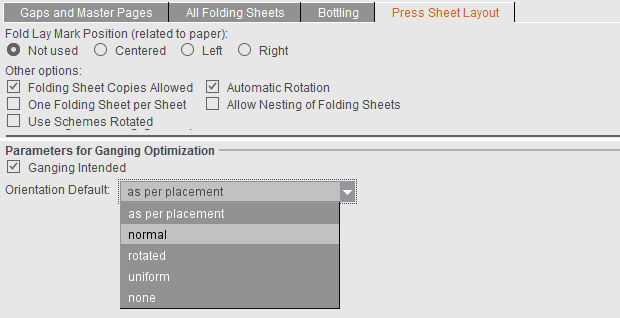

New setting, "none", for "Orientation"

In addition to "normal", "rotated" and "uniform" you can now also select "none" for "Orientation" (orientation of articles to paper grain direction) in the input list for sheet optimization. This means that the best possible placement for the articles is selected during optimization, making it possible for the 1up copies of an article to have different orientations (normal or rotated) in the process for better utilization of the sheet. For example, this can be used for materials without grain direction.

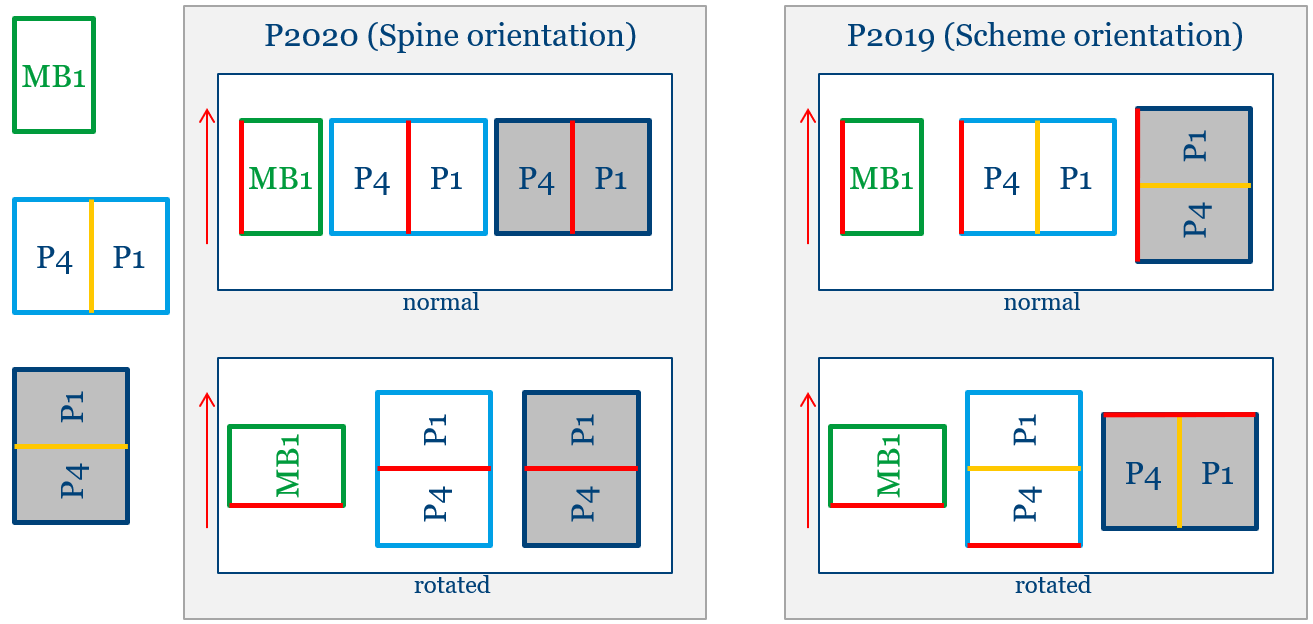

Modified procedure with reference to orientation

Up to version 2019, the "normal" and "rotated" settings for orientation were always interpreted related to the scheme and accordingly set in the gang run form.

As of version 2020 the settings are interpreted as follows:

·For schemes with a folding rule: Back margin orientation

·For schemes without a folding rule: Page orientation

·For Montage: Page orientation

Example: Comparison of the arrangement of an assembly block (MB1), of a vertical and a horizontal fold job in versions 2019 and 2020

New option, "as per placement"

•If "FromLayout" is entered in the gang part XML, orientation is determined from placement in the product part. The grain direction of the paper of the product part is included when determining this value. The result determined is always "normal" or "rotated". As of version 2020, placement can be set by default in Prinect Signa Station as an alternative to determining it from the product part.

For details about these topics, see Input List for Sheet Optimization (grouping table).

Prinect Signa Station Gang Server("Auto Ganging")

More information about processed gang jobs

The view with information for "Planned Gang Jobs" was enhanced.

In the table of the last runs, you can see fast from icons in the result column whether a gang job was run smoothly or whether there were issues, whether the gang pool was empty or the result was rejected because of bad rating. By clicking an icon, you can open either the PDF report or the related error message.

See Planned Gang Jobs .

Enhanced setting options for automated processing

The tasks for planning the automated processing of gang jobs with the Prinect Signa Station Server were enhanced by two setting options:

·Automatic Repeat

New jobs will be created by this gang task until gang jobs can no longer be created from the available gang parts. Only after this is the gang task said to be completed. This is especially important if you are working with the "Only One Press Sheet" option because otherwise all gang parts not placed on this press sheet during the first run would be included only when the gang task next starts.

·Event

In addition to the setting options for the timing of the gang task, you will now also find an event-related start option in "Trigger". This means that this task always starts whenever another task is completed. In this way, you can combine different tasks with each other, for example, to gather the remaining gang parts that were not processed in the predecessor task.

You can combine timing and events with each other.

•In the "Job Import from Gang Pool" dialog, you can customize the size of each of the four main sections individually.

See Job Import from Gang Pool

Creation of blank press sheets

•In the "Imposition" work mode, you can create blank press sheets in the "Plates" step using the "More" button (for example, for front/back end sheets in book production).

See Plates .

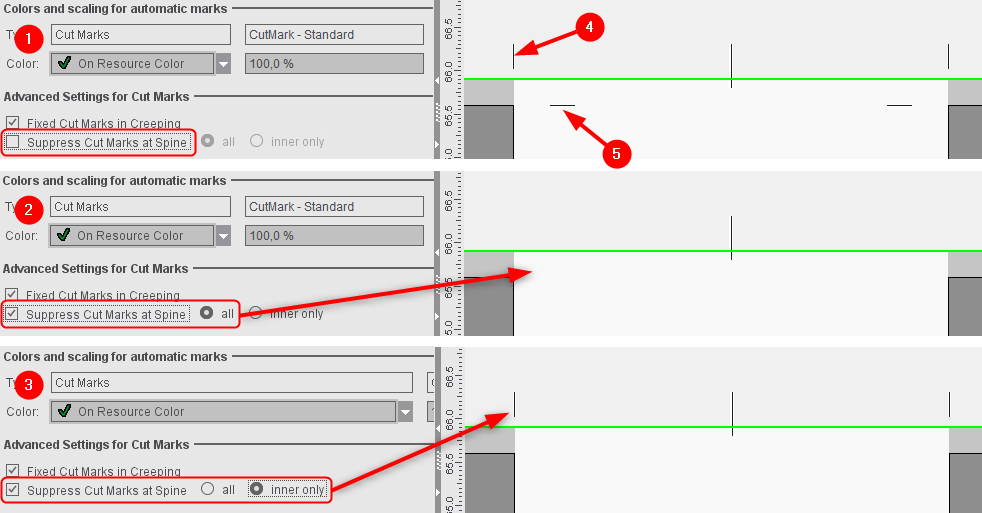

Advanced options when suppressing cut marks at the spine

Cut marks at the spine can be suppressed by default or for a specific job if they are a hindrance in finishing. A new feature as of version 2020 lets you select whether outer and inner cut marks will be suppressed or only the inner cut marks, for example, if the outer cut marks are needed, because there is the risk of "flashes" through the inner cut marks.

For the production of a cover, it can be a good idea to set the cut marks on all corners, for example, when the spine of the cover is not created as an extra page but using the gaps. In this case, the cut marks above the page are wanted but not the cut marks between the pages because these can cause flashes when cutting. For such a case, in the job in "Marks" you can enable "Suppress Cut Marks at Spine" selected with "inner only" (see example no. 3).

Example:

(1): Outer (4) and inner (5) cut marks are output.

(2): All cut marks in the back margin are suppressed.

(3): Only the inner cut marks in the back margin are suppressed to avoid flashes. The outer cut marks are kept.

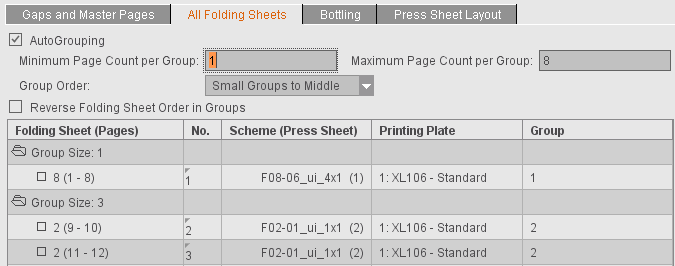

Automatic grouping of the folding sheets

For mixed binding, it is necessary to split the folding sheets into groups that are then put together. Up to now, this grouping had to be done manually and, as a result, products could be produced fully automatically only with set page counts; if the page count changed, grouping had to be done again.

The "AutoGrouping" function now makes it possible to automate this grouping based on certain defaults. Subsequent changes to the page count are also taken into account in this process.

Note: Grouping is possible only in certain binding methods. You can also use "Reverse Folding Sheet Order within Groups" independently of automatic grouping.

"First Folding Sheet is Cover" is now also possible with "Mixed Binding".

More details can be found in All Folding Sheets.

Ignore cover setting during JDF import without cover

In an automated workflow, product part templates are used to define the layout that will be generated. One of the things that the product part templates offer is the option of defining a folding sheet for the cover. If products are to be created that only differ in whether they have a cover or not, you then do not have to create two separate product part templates for this.

If this setting is enabled, the first scheme will be ignored if no cover is specified in the JDF when you are processing a JDF with a product part template where "First Folding Sheet is Cover" is enabled.

This setting affects only product part templates where "Match Folding Sheet Count to Page Total" is enabled.

Include Non-Printable Areas (Graphic View/Press Parameters)

•The press parameters for digital presses like Primefire, for example, were enhanced to be able to enter areas for the lead edge and tail edge of print as well as for margins on the side.

In the graphic view, you can now also display these non-printable areas of the paper in addition to the gripper margins.

See Digital Press Editor and View Properties and Enable/Disable Layers .

You can set inclusion of the gripper margin and the non-printable margins by default when placing 1ups in "Preferences > Defaults > Subject Settings". This is where you will now also find the "Center subject" option (previously in "Several Switches").

You will find the "With Gripper Margin" option that you could select in the "Schemes" step in "Press Sheet Layout" now in the "Plates" step as "Include Gripper Margins and Non-Printable Margins". As a result, the setting no longer generally affects the whole product part but can be set for specific plates, for example, enabled for the cover and disabled for the body.

When the option is enabled, a warning will be issued if subject, folding sheet, bleeds or marks are found in one of the critical areas during output.

For more details, see Subject Settings in the Preferences and Subject Settings in the "Plates" step.

•The "Show Press Template" function now shows details about the positions of grippers and suction cups for the following machines: CD74, CS92, SM52, SM74, SM102, XL75F, XL75C, XL106

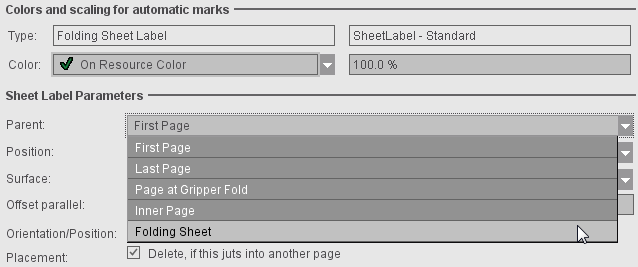

•Set folding sheet label related to folding sheet

Up to now, the folding sheet labels related always to the pages because they were read out only after folding. Newer folding machines are now equipped with barcode readers already at the feeder, making it necessary to assign a related mark to the still unfolded sheet.

See Sheet Label Parameters 1 and 2.

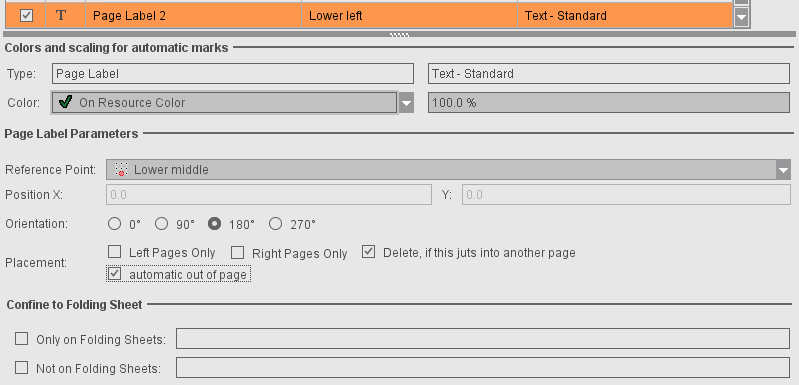

•Position page label automatically off the page

If page labels that jutted into another page were not to be deleted, you could only work around this so far by manually entering a position for the page label. In this case, you had to enter the position in X and/or Y direction related to the reference point. In "Placement", there is now the "AutoPosition off Page" option that sets the mark off the page taking "Orientation" into account. The input boxes for manual positioning are then disabled.

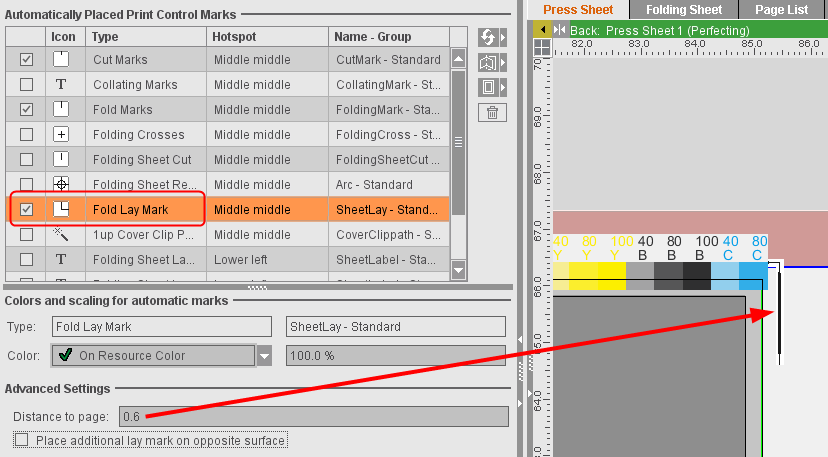

•Fold Lay Mark: Offset to page can be set

Up to now, the automatic fold lay mark was set at a fixed and non-changeable offset of 3 mm to the trimmed page. In certain cases, as a result, the mark could be off the paper. You can now set "Offset to Page" individually. By default, the offset is set to "0.3" = 3 mm. When you change the offset to the page, it is now possible to set the fold lay mark closer to the trimmed page and, consequently, generally into the bleed.

•New attribute, "Do Not Check Mark During Output"

During output, a check is run to see whether a mark is within the gripper margin or out of the paper. If this is the case, a warning is issued. Some special types of marks are excluded from this warning.

Enable "Do Not Check Mark During Output" if marks that are not part of these exceptions are also not to be checked during output.

See "Do Not Check Mark During Output"

•New placeholders: $[SheetRegionGroupIndex], $[MaxSheetRegionGroupIndex], $[SheetRegionInGroup] und $[MaxSheetRegionInGroup]

For finishing, barcode marks are generally used that help to identify a folding sheet. In mixed binding, the folding sheet groups and the relation of the folding sheets are also interesting in this case. The following data are used in finishing:

·Folding sheet group in which the folding sheet is located

·Total number of folding sheet groups

·Folding sheet index in the folding sheet group

·Max. folding sheet index in the folding sheet group

The new placeholders Folding Sheet Group ($[SheetRegionGroupIndex]), Max. Folding Sheet Group ($[MaxSheetRegionGroupIndex]), Folding Sheet Index in Folding Sheet Group ($[SheetRegionInGroup]) and Max. Folding Sheet Index in Folding Sheet Group ($[MaxSheetRegionInGroup]) were introduced to make the data available for marks.

These are found in the group of placeholders that are always replaced by Prinect Signa Station. The placeholders are replaced in the "Imposition" mode and in the "Ganging Optimization" mode. In ganging optimization, the data are read from the gang part analog to the folding sheet number if the folding sheet concerned was sent for ganging from the Cockpit.

•New placeholder "$[GrainDirection]" for paper grain direction

The paper grain direction is defined in the paper resource that is assigned to the press sheet. The new placeholder for paper grain direction is set related to the press sheet and is replaced by the localized text of the paper grain direction.

Note: The arrow for viewing the grain direction has dashed lines in the graphic view if "undefined" is set in the related paper resource or if no paper resource is assigned to the press sheet.

•Multiple selection is now also possible when locking resources and resource groups. If your selection only has resource groups, all resources in them will be locked or unlocked. If your selection is mixed, in other words, you selected resources and resource groups, then only the marked resources will be locked or unlocked.

Locking or unlocking resources makes it necessary to save the resources again and, as a result, saving the resources for job and product part templates can take more time. In this case or if more than 50 resources are locked or unlocked, a progress bar appears, showing you the currently handled resource.

What's New in Prinect Signa Station 2019.10

•In an upgrade, the license configuration of the predecessor version is applied automatically. There is no license request. In this case, the basic version is applied as it is and all available additional options that have at least a floating license are also enabled. In the case of licensing conflicts, these license options may have to be disabled again.

•As early as in the product part template or in the "Schemes" step, you can specify which folding sheets are intended for ganging. You can use this marking to submit these folding sheets automatically to ganging.

See Parameters for Ganging Optimization

•"Only One Press Sheet" option

In the "Sheet Optimization Setup" dialog (invoke with the "Advanced Settings" button), you can set in the "General" tab that exactly one (good) press sheet is to be generated during optimization. After you save your data, gang parts that are not placed are returned automatically to the pool for gang jobs.

See Only One Press Sheet

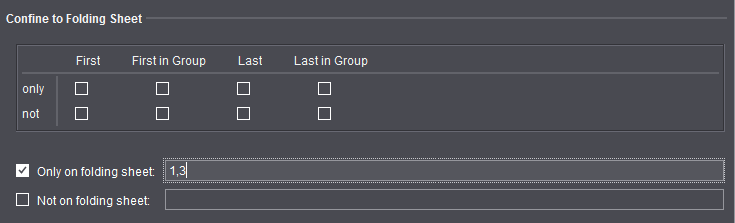

•Confine automatically placed print control marks to certain folding sheets

When you define automatically placed print control marks like cut marks, you can define that these are to be output only on certain folding sheets or that certain folding sheets are to be excluded. With folding sheet labels, you can also make a general selection through the group in addition to specifying the folding sheets directly.

See Sheet Label Parameters 1 and 2 and Confine to Folding Sheet.

•New placeholder "$[QuantityPerSheetRegion]" (delivery quantity per folding sheet)

This placeholder displays the delivery quantity, divided by the number of copies placed on the sheet. It can be used in all modes. If division of the delivery quantity by the number of copies does not give you an integer, the result will be rounded up to the next higher digit. Example: Delivery quantity = 1215, folding sheet X as double 1up on the press sheet, mark set for folding sheet X: 1215/2 = 608 (rounded up)

Background: If the last step of the surface is produced on different machines and not all of the available sheets are to be processed, the mark tells you when the desired delivery quantity is reached.

See also Delivery quantity per folding sheet.

Prinect Signa Station2019: group of placeholders that are always replaced by Prinect Signa Station.

Prinect Signa Station2020: group of placeholders that are always replaced in the workflow.

•$[color all-c] and $[color all-a] placeholders are not replaced only during the output but already during editing. As a result, details can display in the graphic view, in the list view and and in the report.

See also Group: Replacer in Workflow.

Using these placeholders, you can generate marks that output the colors used in the job or on the press sheet as text.

This is pure text replacement. For that reason, for a correct replacement of the color placeholders in the report, it is especially important in the Prinect Cockpit workflow that the colors are already known in Signa Station at the time of output. In other words, that the content is assigned.

The $[color] and $[ColorCode] placeholders continue to be not replaced in the graphic view, in the list view and in the report because these generally overprint during the replacement of all colors. These placeholders are designed for use on the plate.

What's New in Prinect Signa Station 2019

The licensing model has been simplified: The "Prinect Signa Station 52" and "Prinect Signa Station 145+" licensing options have been dropped. As a result, only the two variables, "Prinect Signa Station 75" (max. 75 format) and "Prinect Signa Station 106+" (now the option without a size restriction) now exist.

Existing licenses were transferred accordingly: "Prinect Signa Station 52" licenses have become "Prinect Signa Station 75" and "Prinect Signa Station 145+" licenses have become "Prinect Signa Station 106+".

In addition, there is also the license for the "Label Pro" option.

More details can be found in Licensing

•A different default folder for job import to a gang job can be set for a specific job in the "Product Part" step. The default folder, however, can no longer be changed in the "Job Import from Gang Pool" window. The setting is saved in the job. This means that when the job opens again the setting defined is kept even if the preferences have changed in the meantime.

More details can be found in Default for Gang Pool

•The execution times for automated ganging have become more flexible (selection of single days in the week, several execution times per day).

•The "Planned Tasks" were enhanced by the option of entering two product codes for rating. You can use these to define product codes based on which the gang jobs will either be automatically processed further by the Prinect Cockpit ("green" rating) or stopped for manual correction ("yellow" rating).

See Planned Gang Jobs for more information about these items.

•You can now set the kind of sheet optimization (previously Multiple Sheet Optimization) you want directly below the "Ganging Optimization" work mode.

•In the input list for sheet optimization, you can now also edit the grain direction for gang parts with a double click.

More details can be found in Input List for Sheet Optimization (grouping table)

•In the input list for sheet optimization, in the "Results" step and in the optimization reports, additional information and icons were introduced that provide you at a glance with information about the state of the gang parts.

You can find a description of the meaning of the icons in: Input List for Sheet Optimization (grouping table).

•The "Target Date" column in the "Job Import from Gang Pool" window shows either the set target date or, if available, the date for printing.

More details can be found in Job Import from Gang Pool

•The Product Code Editor was revised to make operation easier and for future setups of the product codes. The functionality was also applied for editing the "Product Code" filter criterion in "Job Import from Gang Pool".

Note: The dialog for creating a product code filter is invoked from the Product Part Template Editor in the "Product Part" step. In the open job, the product code filter displays for your information only if at least one filter criterion is defined.

More details can be found in Product Code Editor

•In the "Product Part" workflow step, you can set a product part template group for the product code search that is different to the one set in the Preferences. In the set group, the gang parts in the ganging workflow are looked for by product code (only with "Sheet Optimization without Layout Default").

•The defaults for the costs in "Sheet Optimization Setup" were adapted:

·"Cost" (tab) > Print Preparation (global)": 50 (previously 250)

·"Cost" (tab) > Print Preparation (per separation)": 50 (previously 0)

·"General" (tab) > Quantity as Multiple of": 1 (previously 100)

·When "Max. No. Articles" is enabled in the "General" tab: 10 (previously 1000000)

•The "Target Date" shows not only the day but also the time in hours:minutes if it is not 00:00 hrs (in the input list in the "Optimization" step, in the "Results" step, in the optimization report and in the "Assembly Block" list view.

•You can now also set the time when you set the deadline. If no time is specified, the time is set to 23:59:59 of the set day. See Edit Deadline .

•New option, "Label Pro", for editing labels. Label Pro can be licensed together with Packaging Pro or separately.

See Licensing for more details or separate "Help Packaging Pro/Label Pro" (invoke with the ? menu).

•New functions in the "Packaging" step if "Label Pro" is licensed: create a CAD file with Label Pro, save as a CAD file and save the CAD file in the tool pool.

See Cutting Die File and Main Settings.

•In the "Packaging" work mode, the assigned PDF files also display in the article table in the "Article" step.

•New tab, "Packaging", in the Preferences for a clearer overview of the preferences for the Packaging mode.

•In the "Packaging" tab, you also set a CAM/CNC machine and the folder where the CAM files will be stored. Using the functions in Label Pro, you can send the layout of a cutting die to a CAM/CNC machine to produce small batches and prototypes. You can find details about Label Pro in its Online Help.

See Packaging.

In the case of version clusters in the JDF workflow where several product parts are needed (e.g. because of a different number of pages, different folding sheets), the various product parts are created automatically during the import. The press sheets are created in the cluster based on the data from the JDF. It is no longer necessary to manually create the deviating product parts for the other versions as was the case up to now.

•New tab, "Ganging Optimization", in the Preferences

This is where you now set the default templates for sheet optimization (previously in "Resources"), the default product part template for the product code search (previously in "Import") and the default folder for the gang parts that will be imported to a gang job. The default for the product code search refers in this case only to sheet optimization. For JDF import, you can select a different default in the "JDF Import" tab.

See Ganging Optimization.

•New tab, "Packaging", in the Preferences

The "Packaging" tab was introduced in the Preferences to make handling of the default easier with the licensed Packaging Pro and/or Label Pro option. The setting for the default folder for CAD files was moved here from the "Paths" tab, the setting for the cutting line type from the "Defaults" tab. Likewise, the defaults for marks relating to the packaging mode are now set in this tab.

See Packaging.

•New editor for "Paper (Printing Material)" resource

With Prinect Signa Station, you can also create or edit a MDS paper resource (including selection of a feed direction). An editor especially for this is now available analog to the Printing Material Editor in the Prinect Cockpit.

See Paper (Printing Material) - MDS Editor.

•New default resources for digital printing

For Labelfire and Primefire, the following resources are now available in their "Standard" group:

Digital presses:

·Labelfire 340

·Primefire 106

Output parameter sets:

·Labelfire 340 (JDF)

·Primefire 106 (JDF)

Plate Templates:

·Labelfire 340

·Primefire 106

•New folding schemes for Heidelberg Stahlfolder TH/KH-82-P, TX96 with Pallet Feeder PFX folding machines

The 27 new folding schemes (L*, S*) follow a set naming scheme and are designed mainly for use of the above-named folding machines with a PFX feeder.

See Folding schemes L* and S*

Optimization of the User Interface

|

•Quick selection via the folder buttons is now available not only for resources but also for resource groups. |

•Selection of folding sheets and pages in the graphic window:

The folding sheet is selected when you click a page first, another click selects the page itself. You can toggle between the two possible selections with each further click. Hold down the Ctrl key when you click if you want multiple selection.

•The behavior of duplicated assembly blocks has been revised to the effect that a change to one duplicate (size, 1up copies) is mapped immediately to the other duplicates if this makes sense.

The parameters in "Position X" and "Position Y" are applicable only for the selected block and also the various margins ("Left Margin", ...) refer only to the active assembly block. The reason for this is that some MIS systems define the position of the various duplicates on the sheet by assigning different margins and, for that reason, different margins must be possible.

•"Subject Position on Paper" in the "Plates" step

To position the subject centered horizontally, up to now you had to disable automatic positioning and enter a value of "0" for the "left" offset. Now you can select "Center Subject Vertically" or "Center Subject Horizontally" to place the subject automatically centered. An input of "0" for the "left" offset now places the subject exactly on the left margin as to be expected.

As of version 2019, jobs from predecessor versions where horizontal centering was set with "Left offset = 0" open automatically with "Center Subject Horizontally" enabled.

•Use smallest suitable paper for the Intent workflow: When determining the production paper, a paper quality for production is sent via the Intent JDF (e.g. Web Shop) that determines the selection of the real paper for layout generation from the MDS. Up to now, the largest paper that still fitted on the plate was used.

In the Intent workflow, the smallest possible paper of suitable quality is now picked from such available papers to keep waste at a low level. In this process, attention is paid to the fact that neither the subject nor the related marks are outside the paper. In addition, the subject and related marks and the marks with a paper reference may not overlap.

If no suitable paper is found, the largest possible paper is used as before.

•The display time for tooltips was upped from 4 seconds to 10 seconds.

New features in the list view

•"Transfer Table Setup (of All Tables) to Server"

The column setup of the list view can now be sent from each Prinect Signa Station to the Prinect Signa Station server and Prinect Signa Station Gang Server and no longer must be set directly on the server. You can send the table setup of one specific list view or you can send the table setups of all list views at one go to the server.

See Context-sensitive menu on items in the table (all lists)

•Additional "Rating" column in the press sheet list view

If the press sheets were generated using sheet optimization, then quality criteria are applied to the generated press sheets. These produce a rating that results in one of the three traffic light colors (green, yellow, red) and the extent to which the state is achieved in percent. This rating already displays in the "Results" workflow step and in the HTML report on optimization. You can now also show the values in an additional column in the press sheet list view.

The "Rating" column is automatically hidden if the column is in the table setup but the open job is not a sheet optimization one. If the table setup opens in such a case, the column is tagged by a * indicating that it is not relevant for the current work mode.

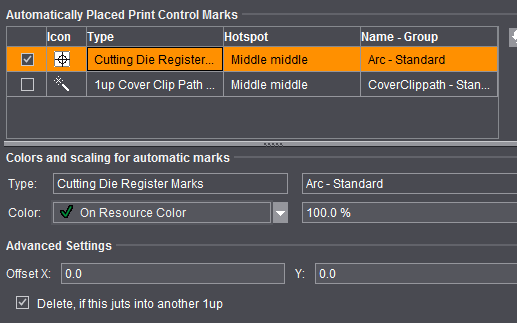

•New automatic mark, "Cutting Die Register Marks"

In the "Marks" step, automatic "cutting die register marks" can be added to the corners of each cutting die (with offset). The positions of these marks are sent to the cutter that "punches" the cutting die (especially for CAM/CNC machines).

Refer also to "Mark Type".

•New default marks: "NelaPlateControl" and "NelaPlateControlDetails"

A particular structure for a Data Matrix mark was agreed upon with Nela for the interaction with Nela plate logistic systems so that the mark to be imaged on the plate contains all the necessary information, for example, to be correctly assigned to the plate stacker. The new "NelaPlateControl" mark in the "Standard" group is equivalent to the SF-NELA-Prinect barcode definition. The "NelaPlateControlDetails" mark shows the content of the "NelaPlateControl" mark in plain text.

See also Standard Marks.

•Position fold lay mark also on opposite surface

To date, the fold lay mark was positioned always as set for the fold lay mark defined in the scheme (generally the back). The new "Position additional lay mark on opposite surface" option lets you place an additional fold lay mark on the opposite surface (generally the front).

See also Fold Lay Mark.

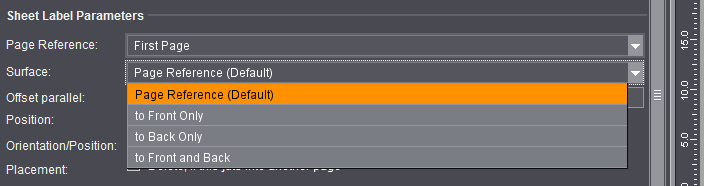

•Set surfaces for folding sheet label

You can now also directly set the surface on which the folding sheet/assembly block label will be placed in addition to doing this through the page reference. You can select between four different settings in "Marks > Sheet Label Parameters > Surface". The only option to date ("Placement > to Front and Back") has been dropped as a result because this is one of the possible options in "Surface".

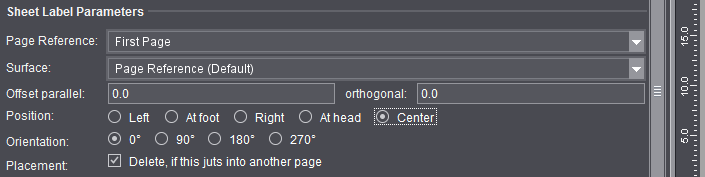

•Set orientation of the folding sheet label in steps of 90°

Up to now, the folding sheet label could be output rotated only by 180°. When you select "Center" as the position, you can now set rotation either by 90°, 180° or 270° in "Orientation".

•An additional feature, "Move to Page Center", was introduced for the folding sheet label to be able to place it automatically centered to the page in the spine. The folding sheet label can be automatically placed centered to the page in the spine if this option is enabled and the right page reference and hotspot of the mark are selected.

See Sheet Label Parameters 1 and 2 for more information about these items.

•Color Control Mark (with AutoClip to subject) - new parameter: Bottom/Top Margin

A margin with paper white around the color control mark is needed so that Inpress Control and Image Control can measure these strips properly. To date, color control marks with AutoClip are placed directly onto the side and, as a result, there is no such margin. In the Color Control Bar Editor, two additional boxes are now available in "Color Control Mark (with AutoClip)": "Bottom Margin" and "Top Margin". This margin is included when looking for free space on the paper, with the result that the color control bar is no longer positioned directly on the side.

See Additional Attributes for Color Control Marks

•Barcode marks freely scalable by selecting "User-defined" as the "Module Width"

•New tool, "Barcode object", in the Marks Editor

This lets you create Marks Editor marks to which barcodes can be inserted as graphic objects. The settings that are possible are equivalent to those in the Barcode Editor. In addition, you can define the starting point (bottom left corner of the barcode) on the canvas analog to the other graphic objects. You can create ASIR marks with this function without "IDAutomation" as the font.

See Graphic Area

•New setting for text marks: "Mark Height"

Select between "Default" (previous performance with margin), "Compact" (smaller clip path) and "Very compact" (smallest possible height, descenders are cut off).

See Creating a Text Mark

New features with placeholders

•$[PressID]

The new placeholder, $[PressID], is not replaced by Prinect Signa Station but in the workflow by the Prinect Cockpit. It is replaced by the press ID.

•$[SurfaceCharacter], $[PlateSizeX], $[PlateSizeY]

A particular structure for a Data Matrix mark was agreed upon with Nela for the interaction with Nela plate logistic systems so that the mark to be imaged on the plate can transport all necessary information. The new placeholder, $[SurfaceCharacter], is replaced by front surfaces ("F) and back surfaces ("B). The $[PlateSizeX] and $[PlateSizeY] placeholders are replaced by the plate size.

•$[PressSheetGangPartOneUpCount], $[PressSheetCopiesOfGangPartOneUp], $[GangPartOneUpCount], $[CopiesOfGangPartOneUp]

For gang jobs, the information about how many gang parts are on the sheet and how many copies per gang part are on the sheet is important for finishing. The new placeholders now make the required information available.

•$[PrintDate]

Only when you have the gang run form is it clear which processing steps are needed to process all the products on this sheet. The print date results counted back from the target dates.

•$[LastFoldingSheetMarker]

Identifies the last folding sheet of the source job

•$[JobCounter]

Names the job in the AutoGang environment (replaced by Prinect Integration Manager).

•$[DocumentCreationDate], $[DocumentModificationDate]

Using this, the modification and/or creation date of the PDF document can be output in a page-related text mark, for example, to be able to detect the various versions of correction PDFs of the same name during proofing.

See List of implemented placeholders for text marks by groups for a description of the new placeholders.

•Formats for layer placeholders

Placeholders showing layer-specific data, like the name of the assigned PDF document, to date always showed the data of the last active layer (generally the desired layer in versioned jobs). The new format makes it possible to replace the data for the layer specified in the placeholder.

•Formats for unit-specific placeholders

Placeholders that are unit-specific, in other words where the unit set in the Preferences plays a part, to date were always output in the unit set by default. It is now possible to show this in a unit that deviates from the Preferences.

•Formatting of date placeholders

You can set the date and time in very different ways. This can be done through formatting because it is pointless to provide a separate placeholder for each possible notation. To format a date placeholder, the introductory formatting character, the colon, is followed by "@" and after that the date format is set.

See Formats for placeholders for information about the formats.

The Online Help is launched via a URL link on a Heidelberg WEB server. If a computer does not have direct access to the Internet, the Help feature is routed through the PMC to the Internet. Online Help is no longer installed locally. This reduces the data volume during updates and you always have the latest Help contents.