Automatic Ganging with the Prinect Signa Station Gang Server ("Auto Ganging")

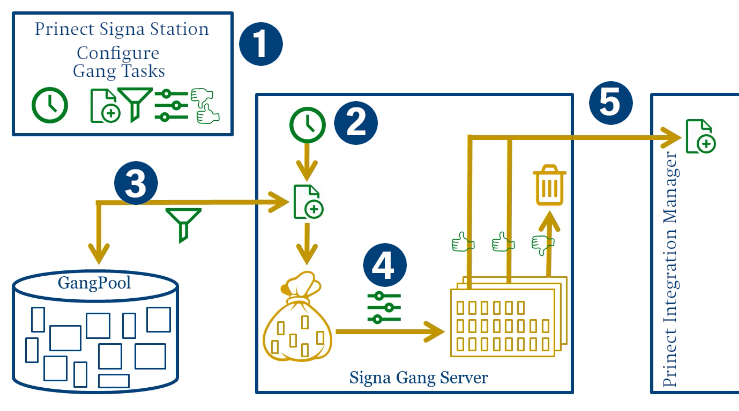

You can schedule various tasks that then automatically create ganging optimization layouts. These time-controlled tasks are processed accordingly by the Prinect Signa Station Gang Server. In this process, the set gang pool is scanned for certain criteria (e.g. paper, delivery date) and if paper utilization is satisfactory and production costs are low, the Prinect Signa Station Gang Server automatically creates a gang run form that is then used to create a new job in the Prinect Integration Manager.

Prerequisite: This requires the "Gang & Sheet Optimizer" license in addition to the Prinect Signa Station Server.

•Step 1: Preparations for the setup of the gang tasks (timing, filter rules, settings for processing, see Gang Tasks Configuration)

Automatic workflow:

•Depending on the timing, a job starts and is named by the naming rules. (2)

If need be, output can be started directly by the user.

•The gang pool is scanned based on the filter criteria. (3)

You can follow the processing stage in the status display in the "Planned Tasks" dialog.

•In the job, processing of the gathered gang parts then runs based on the data of the set product part template and optimization starts. (4)

•The result sheets are assessed sheet for sheet and all sheets considered good are submitted to the Prinect Integration Manager. (5)

By contrast, sheets that did not meet the rating criterion are deleted, and the gang jobs placed on them are returned to the gang pool.

•Then the resulting layout is written to the default output folder (you can also see the path to the layout in the "Planned Tasks" dialog). Information displays if an error occurred before or during the optimization run (e.g. no matching gang jobs found or no sheet met the criteria).

•If "Prinect" is set as the output workflow in the output parameter set used to output the optimized layout (Device: "Prinect" and variant: "Prinect Cockpit xx (via JDF)"), then the layout is sent automatically to the Prinect system. As a result, a new job in the Prinect Integration Manager is created by Prinect Signa Station.

Depending on the setting for the job number/job name, the layout can then be imported to an existing Prinect job or to a new one.

The following settings must be defined for the automatic processing of tasks:

|

|

Define the output parameter set that controls output, for example, "Device", "Prinect" and "Variant" "Prinect Cockpit (per JDF)" for creating a job directly in the Prinect Integration Manager |

"Resources > Output Parameter Set" |

|

Define the plate template and assign the output parameter set you want in "Output" |

"Resources > Plate Template" |

|

|

|

Define the sheet optimization setup that controls optimization and if necessary has the rating criteria for sorting out sheets with insufficient utilization of the sheet |

"Resources> Sheet Optimization Setup" |

|

|

Define the product part template for processing In the product part template: •In "Product Part" set "Ganging Optimization" as the work mode and enable "Create Prinect Job". •In "Plates" assign the plate templates and with them the output parameters. •In "Optimization" set the sheet optimization setup you want directly or assign a predefined sheet optimization setup. |

"Resources > Product Part Templates" |

|

|

Define filter rules In the "Job Import from Gang Pool" dialog or in the resources, you can define various filters with different criteria on the left that not only impact the display in the dialog but also can be selected when creating the tasks. For example, the filters can be used to filter the gang pool by certain printing materials or by delivery quantities. |

"Tools > Job Import from Gang Pool" |

|

|

Schedule tasks This is where you actually define the automatic tasks. You define the names to be assigned to the jobs, assign the product part template created for processing and the filter rule to be used. |

"Tools> Planned Gang Jobs" |