You will find a detailed description of how to work with marks in Working with Marks.

You can set the following parameters in the "Marks" step:

•Set/remove automatic print control marks

•Define positioning, colors and scaling for automatic marks

•Confine the placement related to the folding sheets

Note: When a job is reloaded, the marks and automarks sets used are compared with the current resources and can be refreshed if needed. Automarks sets modified in the job (tagged by "*") are not automatically synchronized.

Automatically Placed Print Control Marks

Cut marks, fold marks, collating marks, folding crosses, folding sheet cuts, fold lay marks, 1up ID, 1up cover clip path mark and folding sheet labels are automatically set for the product part if you enable this.

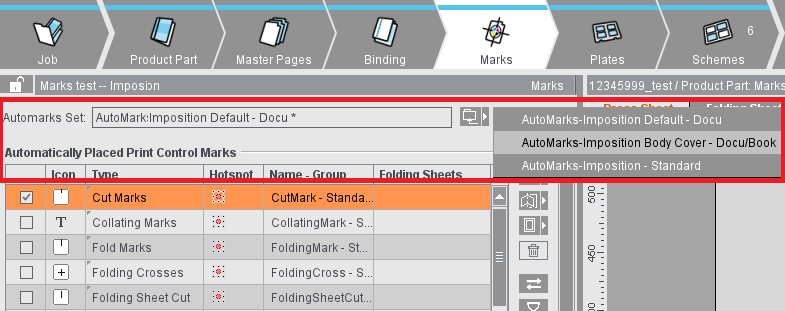

In a new job, the automarks set defined in the Preferences for the selected work mode is used. The set used displays in the "Automarks Set" box. In the job, you can select a different automarks set from the Resources using the folder button or customize specific settings for the job. The automarks set used and the Resources folder display in the upper box. Only the automarks sets matching the selected work mode display in the "Choose Mark" dialog.

Changes to the automarks set affect only the job in question and not the resource. Automarks sets that differ from the resource are tagged by a "*". During a comparison of the settings within the job with the resources, modified configurations are ignored to avoid unwanted changes within the job. You can also save the modified set from the job to the Resources using the Save button (either as a new set or by overwriting an existing set).

You can create and edit automarks sets not only in the Resources but also in the job in the "Marks" step and save them to the Resources from there. The editor for creating automarks sets in the Resources and the editor in the job have only slight different functions. To give you a better overview of the use of automarks, the topic is described in a separate section: Automarks

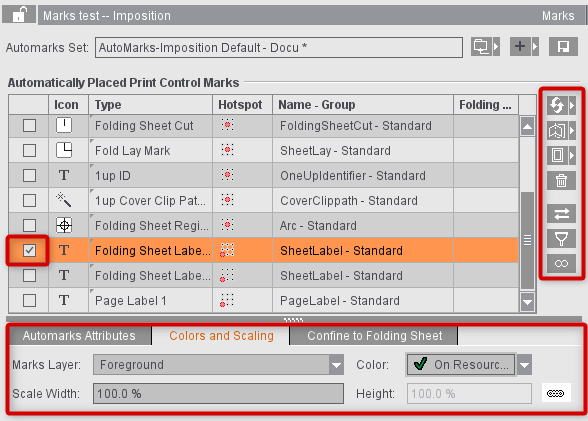

The table gives you a clearer overview of the default parameters and configuration of the print control marks:

•When you select an inactive mark, its parameters show below the table (cannot be edited).

•When you enable and select a mark, you can edit its parameters below the table.

The automatically placed cut and fold marks cannot be changed for now because the positions of these marks are always unique. You can modify them only by explicitly disabling the automatic function in the graphic window. More details can be found in Automatic Function for Automatic Cut and Fold Marks.

You can then select and modify all other automatic mark types in the graphic window.

Note: You can find details about the settings for marks in the following sections:

Automarks Attributes

Colors and Scaling for Automatic Marks

Confine to Folding Sheet

Note: The "1up ID" mark was designed especially for gang jobs or for multiple sheet optimization. More details can be found in Introduction to a Gang Job with Sheet Optimiza-tion.

When cut and fold marks are set, the program always checks whether the gaps on the folding sheet/assembly block are big enough for the automatic marks and for the page bleed. If necessary, the marks are deleted and the bleed reduced so that they don't jut into the adjacent page. This applies for front and back printing.

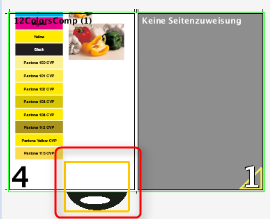

The cut and folding marks can no longer be modified. These elements are indicated by a red frame in the graphic window when you select them.

The automatic fit for bleeds is not used if a custom bleed is set on a special master page. There are special cases where a bleed must jut into the adjacent page. You can allow this by creating a special master page with a custom bleed ("Master Pages" step). In addition, you can disable the "AutoReduce Bleed" option in the Page/1up Inspector.

The cut marks are set in relation to the page and are listed in the Page/1up Inspector in the "Marks" step (see also Page/1up Inspector).

The fold marks, folding crosses, folding sheet cuts, fold lay marks and collating marks are set in relation to the folding sheet and are listed in the Folding Sheet Inspector in the "Marks" step (see also Folding Sheet Inspector, Marks).

Automatically placed print control marks are set per folding sheet or page. Using rules, you can use different automarks configurations within a job, depending on the folding sheet. For example, the cover is to have different marks and parameters to the body or there are to be different marks configurations for various customers.

Note: At present, you can create rules only for automarks configurations for the "Imposition" work mode.

For more details, see: Automarks

Manually set marks are handled based on the following rule:

All folding sheets and press sheets are fully recalculated if you change the layout in the product part, e.g. page size, gaps, paper size. etc. In this case, any manually set marks are lost. The layout is not recalculated and the marks are kept with other types of changes such as creeping on/off, position of the page contents, etc.

You can only select automatically set marks in the "Marks" step. You can set manual marks in the Press Sheet Inspector, Folding Sheet/Assembly Block Inspector and Page/1up Inspector.

Assembly block labels (Montage only)

You can use this automatic mark only in the "Montage" work mode. The mark is not set by default.

Marks that provide additional information about the assembly block are required analog to the folding sheet label in the "Imposition" mode.

Precutting marks (Montage only)

You can use this automatic mark only in the "Montage" work mode. The mark is not set by default.

Precutting marks are set on the margins of the assembly block. If precutting marks are active and set for the selected assembly block, a check is also run to see whether the gaps are at least the sum of the margins. This check makes sure that, when two assembly blocks abut each other, the precutting marks of one assembly block do not cut away the content of the other assembly block. If this is done, a warning triangle displays in the "Gaps" text box. Your attention is drawn to the issue in the tooltip of the text box.

Precutting marks may jut into another page when these marks are used for CAD assembly blocks (e.g. if the CAD assembly block does not have a shape). Nevertheless, precutting marks are wanted for precutting assembly blocks.

You can control whether the precutting marks will be removed or kept with the "Delete, if this juts into another page" option.

You can use the automatic mark in the "Imposition", "Montage" and "Packaging" work modes. The mark is not set by default.

A Cover Clip Path mark is set automatically to every page/1up with this type of mark. This prevents marks set to "Background" jutting into the page/1up content or overlapping white parts within the bleed box.